Customization and Flow Forming Machine Technology: A Perfect Match

Flow Forming Machine Technology has been gaining popularity in the ever-evolving landscape of manufacturing technology. This innovative process has transformed industries, providing an effective and efficient way to create custom metal spinning parts for a wide range of applications. With its exceptional versatility and precision, Flow Forming Machine Technology has become a perfect match for businesses looking to meet the growing demand for tailored solutions.

Understanding Flow Forming Machine Technology

Flow Forming Machine Technology, also known as spin forming, is a metalworking process that involves the gradual reduction of a metal tube’s diameter. This process occurs through the rotation of the workpiece while a set of rollers shape and form it.

The metal becomes thinner and takes on the desired shape. The key advantage of this technology is its ability to produce parts with high precision and tight tolerances, making it an ideal choice for applications where customization is critical.

Custom Metal Spinning Parts — Flow Forming Machine Technology

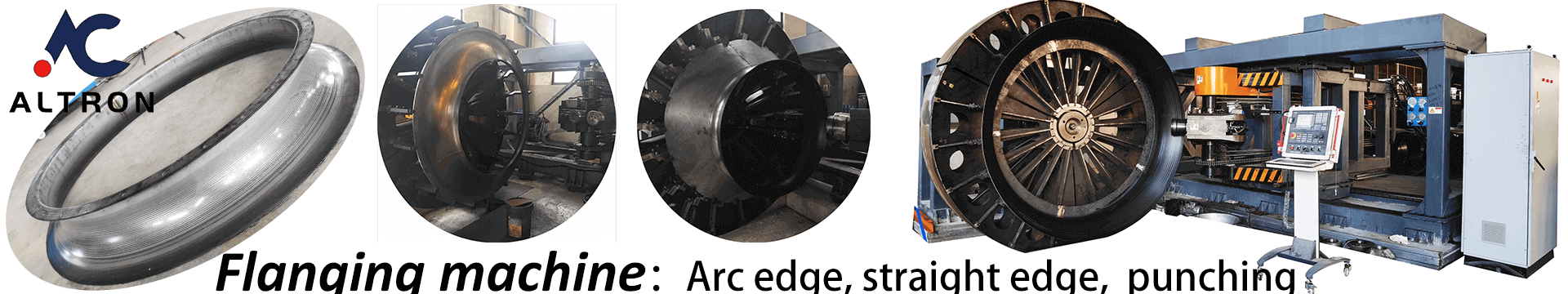

ALTRON, a leading manufacturer with a full production chain, including fiber laser cutting machines, 20+ CNC spinning machines, deep drawing machines, punching machines, and molds, has harnessed the potential of Flow Forming Machine Technology to provide custom metal spinning parts that cater to a diverse set of industries.

Whether it’s for the building and fire sector, musical instruments and crafts, automotive parts, or pressure vessels, Flow Forming Machine Technology has enabled ALTRON to offer tailor-made solutions that meet the unique needs of its clients.

Case Studies: Success Stories in Industry Transformation with Flow Forming Machine Technology

1. Building & Fire Industry Transformation

ALTRON’s involvement in the building and fire industry is a testament to the transformative power of Flow Forming Machine Technology. Building and fire safety regulations continually evolve, necessitating specialized components that can withstand the most demanding conditions. By utilizing Flow Forming Machine Technology, ALTRON has been able to craft custom metal spinning parts that not only meet these stringent requirements but also exceed them.

Their products include fire suppression system components, building connectors, and other essential parts. The customization made possible by it allows ALTRON to adapt to the specific needs of each project, ensuring that their clients can confidently comply with all safety regulations.

2. Musical Instruments & Crafts

The musical instruments and crafts industry is another sector where Flow Forming Machine Technology has made a significant impact. ALTRON has successfully provided bespoke components for musical instruments such as brass and woodwind instruments, as well as unique decorative elements for various crafts.

It enable ALTRON to achieve the precision required in crafting these components, ensuring that the final products meet the exacting standards of musicians and artists. The customization extends to not only the design and shape of the components but also the choice of materials, allowing for the creation of lightweight yet durable parts.

3. Automotive Parts

In the automotive industry, precision and durability are of paramount importance. ALTRON has leveraged Flow Forming Machine Technology to manufacture custom metal spinning parts for various automotive applications, from suspension components to exhaust systems.

The ability to customize parts according to the unique specifications of different vehicle models has allowed ALTRON to become a preferred partner for automotive manufacturers. Their ability to deliver high-performance, tailor-made components has resulted in increased efficiency, reduced costs, and improved overall quality in the automotive sector.

4. Pressure Vessel Manufacturing

Pressure vessels are essential components in industries such as oil and gas, chemical processing, and power generation. These vessels must adhere to stringent safety standards, making customization a critical requirement. ALTRON has successfully used Flow Forming Machine Technology to create custom pressure vessel components that meet the specific needs of their clients.

The ability to customize the thickness and shape of pressure vessel components, while maintaining the necessary structural integrity, is a hallmark of Flow Forming Machine Technology. ALTRON’s commitment to precision and quality has made it a trusted partner for companies in need of reliable pressure vessel solutions.

5. Customization: A Game-Changer

Customization is a game-changer in today’s manufacturing landscape. As industries evolve and demand unique solutions, the ability to tailor components to precise specifications is a competitive advantage. Flow Forming Machine Technology empowers manufacturers like ALTRON to deliver on this promise. By embracing this technology, they can offer their clients components that are not only high-quality and reliable but also perfectly aligned with their specific needs.

Flow Forming Machine Technology at ALTRON: The Key to Success

ALTRON’s journey to success in a wide range of industries is intrinsically linked to its adoption of Flow Forming Machine Technology. With a focus on precision, customization, and quality, ALTRON has become a key player in the manufacturing landscape. Their investment in a diverse range of machinery, including fiber laser cutting machines, CNC spinning machines, deep drawing machines, and punching machines, combined with their expertise in molds and surface treatment, has been instrumental in their ability to meet the diverse needs of their clients.

In the face of industry transformations, ALTRON has consistently adapted and thrived by integrating it into their production processes. This technology has allowed them to achieve levels of precision, efficiency, and customization that were previously unimaginable. Whether it’s creating parts for the building and fire industry, crafting components for musical instruments and crafts, manufacturing automotive parts, or supplying pressure vessel components, Flow Forming Machine Technology has been their ally in delivering tailor-made solutions to their clients.

In Conclusion

Flow Forming Machine Technology is a driving force behind the success of manufacturers like ALTRON. It enables them to provide their clients with custom metal spinning parts that are perfectly suited to their specific needs. The flexibility, precision, and efficiency of this technology have transformed industries and allowed businesses to thrive in the face of change. As we continue to witness innovation and evolution in the manufacturing landscape, it’s clear that customization through it is a perfect match for those looking to stand out and deliver excellence in their respective industries.