What are the Key Factors Influencing the CNC Metal Spinning Machine Price?

Delve into the intricacies of CNC Metal Spinning Machine Price, exploring factors like specifications, brand reputation, and comparative advantages over traditional methods. Learn why Altron Auto emerges as a top choice, offering innovative designs, comprehensive support, and long-term cost efficiency. Make informed decisions to optimize your manufacturing processes.

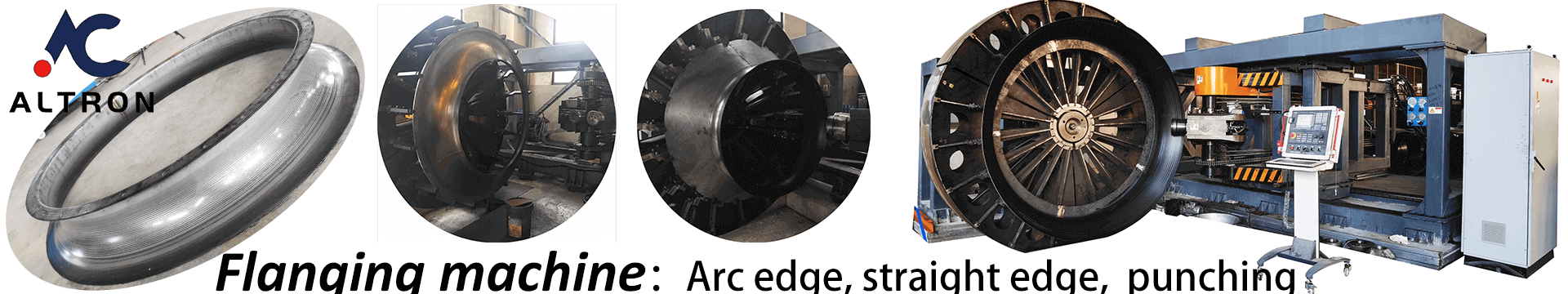

Introduction to CNC Metal Spinning Machines

CNC metal spinning machines are pivotal in modern manufacturing processes, revolutionizing how metal components are formed. These machines utilize computer numerical control (CNC) technology to automate the spinning process, enabling precise and efficient production of various metal shapes and sizes.

1.1 Definition and basic functionality

CNC metal spinning machines are designed to shape metal sheets or blanks into desired forms through a spinning motion. This spinning action is achieved by rotating the workpiece on a mandrel while simultaneously applying force with tools or rollers. The CNC aspect allows for precise control over the spinning process, including speed, direction, and tool movements.

1.2 Importance in modern manufacturing processes

These machines play a crucial role in industries such as automotive, aerospace, and household appliance manufacturing. They offer flexibility in producing complex shapes and designs with high accuracy and repeatability. CNC metal spinning machines also contribute to cost reduction and faster production cycles compared to traditional methods like casting or forging.

Understanding the Working Principle of CNC Metal Spinning Machines

CNC metal spinning machines operate on a straightforward principle but involve intricate mechanisms to achieve precise results.

2.1 Detailed explanation of how the machine operates

The process begins with securing a metal blank onto a rotating mandrel mounted on the machine. As the mandrel rotates, a CNC-controlled tool or roller presses against the blank, gradually forming it into the desired shape. The machine’s computerized system precisely controls the spinning speed, tool movements, and pressure exerted on the blank, ensuring consistent and accurate results.

2.2 Components involved in the spinning process

Key components of CNC metal spinning machines include the mandrel, which holds the workpiece in place, the spinning tool or roller, and the CNC control unit. Additionally, some machines may feature automated loading and unloading systems, further enhancing productivity.

Advantages of CNC Metal Spinning Machines

CNC metal spinning machines offer several advantages over traditional metal forming methods, making them a preferred choice for many manufacturers.

3.1 Efficiency and precision

One of the primary advantages of CNC metal spinning machines is their ability to produce intricate shapes with high precision. The CNC control allows for fine adjustments, resulting in consistent part dimensions and surface finishes. Moreover, the automated nature of these machines reduces manual labor and production time, increasing overall efficiency.

3.2 Versatility in handling various metals and shapes

CNC metal spinning machines can work with a wide range of metals, including aluminum, stainless steel, and copper, as well as different thicknesses and sizes of blanks. This versatility makes them suitable for diverse applications across various industries, from forming simple cylinders to complex geometric shapes.

3.3 Cost-effectiveness compared to alternative methods

Despite their advanced capabilities, CNC metal spinning machines offer cost-effective solutions for metal forming. They eliminate the need for expensive molds or dies required in processes like casting or stamping. Additionally, the efficient use of material minimizes waste, further reducing production costs.

Factors Influencing CNC Metal Spinning Machine Price

Several factors contribute to the CNC Metal Spinning Machine Price, including machine specifications, features, and brand reputation.

4.1 Machine Specifications and Features

The size, capacity, and technical specifications of CNC metal spinning machines significantly impact their prices. Larger machines with higher capacity and advanced features command higher prices due to their increased capabilities and production efficiency. Altron Auto offers a diverse range of machines tailored to meet different production requirements, ensuring there’s an option suitable for every budget and application.

4.2 Automation and Advanced Features

CNC metal spinning machines equipped with advanced automation features tend to be priced higher due to the added convenience and productivity they offer. Altron Auto’s machines often come with state-of-the-art automation capabilities, such as robotic loading and unloading systems and integrated quality control mechanisms. While these features may increase the initial investment, they result in long-term cost savings and enhanced operational efficiency.

4.3 Brand Reputation and Quality

The reputation and reliability of the manufacturer also play a significant role in determining the price of CNC metal spinning machines. Altron Auto has earned a reputation for producing high-quality, durable machines known for their precision and performance. Investing in a reputable brand like Altron Auto ensures reliability, superior build quality, and comprehensive after-sales support, mitigating the risk of unexpected downtime and costly repairs.

Comparative Analysis with Other Metal Forming Equipment

While CNC metal spinning machines may seem costly upfront, they offer several advantages over traditional metal forming equipment, making them a worthwhile investment for manufacturers.

5.1 Versatility and Flexibility

CNC metal spinning machines offer unparalleled versatility and flexibility, allowing manufacturers to produce a wide range of complex shapes and designs with high precision. Unlike traditional methods such as casting or stamping, which require costly molds or dies, CNC metal spinning machines can produce parts directly from metal blanks, reducing tooling expenses and setup time.

5.2 Cost-Effectiveness

Despite their initial investment costs, CNC metal spinning machines offer long-term cost savings and operational efficiencies. By eliminating the need for expensive tooling and reducing material waste, these machines help manufacturers optimize production processes and minimize overhead costs. Altron Auto’s machines are designed to maximize efficiency and productivity, ensuring a high return on investment over time.

Why Choose Altron Auto

Altron Auto stands out as a preferred manufacturer of CNC metal spinning machines due to its commitment to quality, innovation, and customer satisfaction.

6.1 Innovative Designs and Technology

Altron Auto continually invests in research and development to innovate and improve its machine designs and technology. This dedication to innovation ensures that customers have access to cutting-edge solutions that meet their evolving needs and exceed industry standards.

6.2 Comprehensive Support and Services

In addition to manufacturing high-quality machines, Altron Auto offers comprehensive support and services to its customers. From installation and training to maintenance and technical support, Altron Auto’s team of experts is committed to helping customers maximize the performance and efficiency of their machines throughout their lifecycle.

Average Price Range for CNC Metal Spinning Machines

When considering the investment in a CNC metal spinning machine, understanding the average CNC Metal Spinning Machine Price range based on machine specifications is crucial. Prices can vary significantly depending on factors such as size, capacity, automation level, and brand reputation.

7.1 Analysis of price points based on machine specifications

CNC metal spinning machines come in various sizes and configurations, each catering to specific production needs. Smaller machines with limited capacity may start at around $50,000, while larger, high-capacity models can exceed $500,000 or more. The price typically increases with additional features such as advanced automation, precision control systems, and integrated quality assurance tools.

7.2 Comparison with other metal-forming equipment

In comparison to other metal forming equipment such as CNC machining centers or stamping presses, CNC metal spinning machines generally fall within a similar price range. However, they offer distinct advantages in terms of flexibility, versatility, and cost-effectiveness, especially for producing complex shapes or low-volume parts. While initial investment costs may be higher, the overall operational efficiency and reduced tooling expenses often justify the expense.

Key Manufacturers and Their Product Offerings

Several manufacturers specialize in CNC metal spinning machines, each offering a range of models with varying capabilities and features.

8.1 Overview of leading companies in the industry

One prominent manufacturer in the CNC metal spinning machine market is Altron Auto. Known for its innovative designs and high-quality craftsmanship, Altron Auto has established itself as a leader in the industry. Other notable manufacturers include PNC Spinning, Lien Chieh Machinery, and Leifeld Metal Spinning.

8.2 Highlighting notable CNC metal spinning machine models

Altron Auto offers a diverse range of CNC metal spinning machines tailored to meet different production requirements. Their flagship models, such as the Altron 1000X and Altron 2000X series, are equipped with advanced CNC controls, precision tooling systems, and robust construction for reliable performance. These machines are capable of handling various metals, including aluminum, stainless steel, and titanium, making them suitable for a wide range of applications across industries.

Tips for Selecting the Right CNC Metal Spinning Machine

Choosing the right CNC metal spinning machine requires careful consideration of various factors to ensure it meets production needs effectively and efficiently.

9.1 Assessing production needs and capabilities

Before investing in a CNC metal spinning machine, manufacturers should assess their production requirements, including anticipated production volumes, part complexity, and material specifications. Understanding these factors helps determine the appropriate machine size, capacity, and features needed to meet production goals.

9.2 Evaluating technical specifications and features

When evaluating CNC metal spinning machines, manufacturers should pay close attention to technical specifications such as spindle speed, tooling options, axis configuration, and CNC control capabilities. Additionally, features like automated loading and unloading systems, real-time monitoring, and predictive maintenance capabilities can enhance productivity and streamline operations.

9.3 Considering long-term maintenance and support

Choosing a reputable manufacturer like Altron Auto ensures access to reliable maintenance and support services throughout the machine’s lifecycle. Manufacturers should inquire about warranty coverage, training programs, and spare parts availability to ensure minimal downtime and maximum operational efficiency.

Conclusion

In conclusion, CNC metal spinning machines offer a cost-effective and efficient solution for metal forming in modern manufacturing processes. Their ability to produce precise and complex shapes with high repeatability makes them indispensable tools across various industries. While the price of these machines may vary based on factors such as size, capacity, and features, investing in a quality CNC metal spinning machine can yield significant long-term benefits for manufacturers.