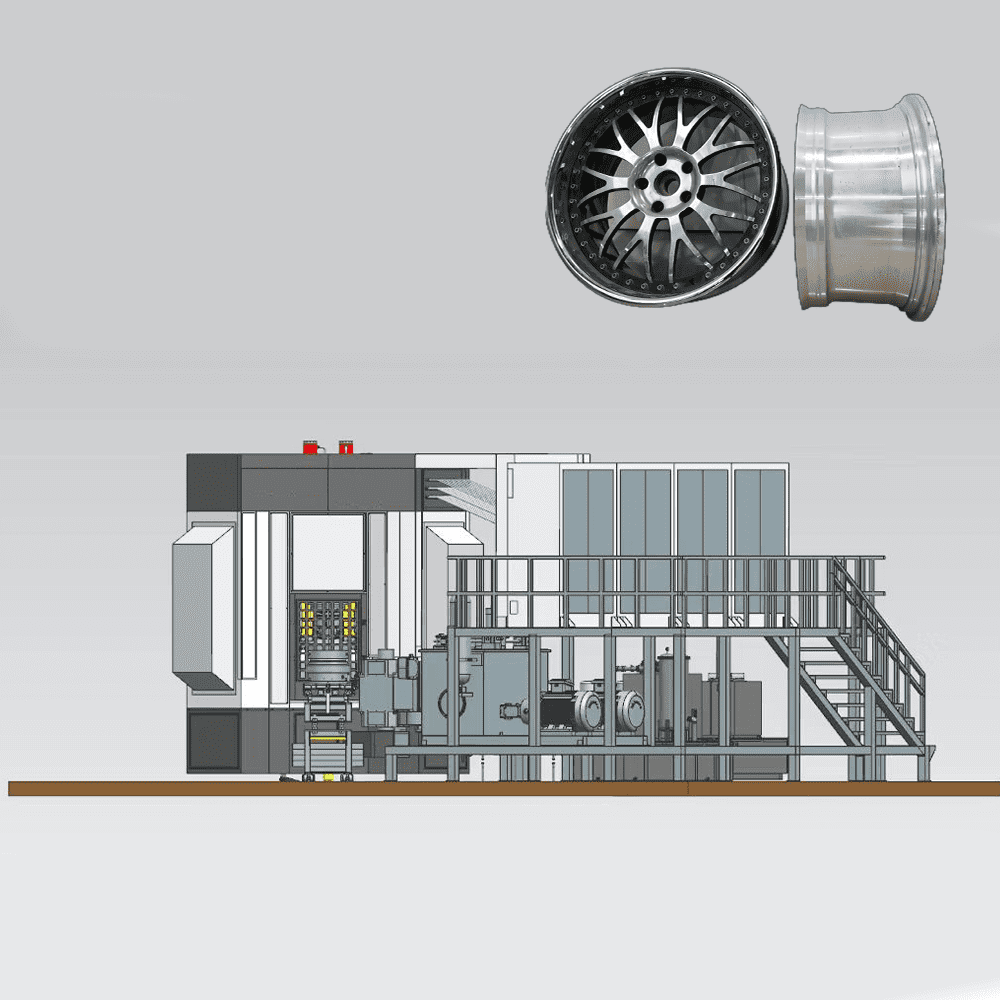

Aluminum Alloy Hub Powerful Spinning Machine

Aluminum Alloy Hub Powerful Spinning Machine

|

Machine Name |

Aluminum Alloy Hub Powerful Spinning Machine |

|

Model |

AC-700/2 |

|

Application Industry |

Casting Wheel Hub, forging Wheel Hub, Car Wheel Hub,Aluminum Alloy Hub |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours/7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

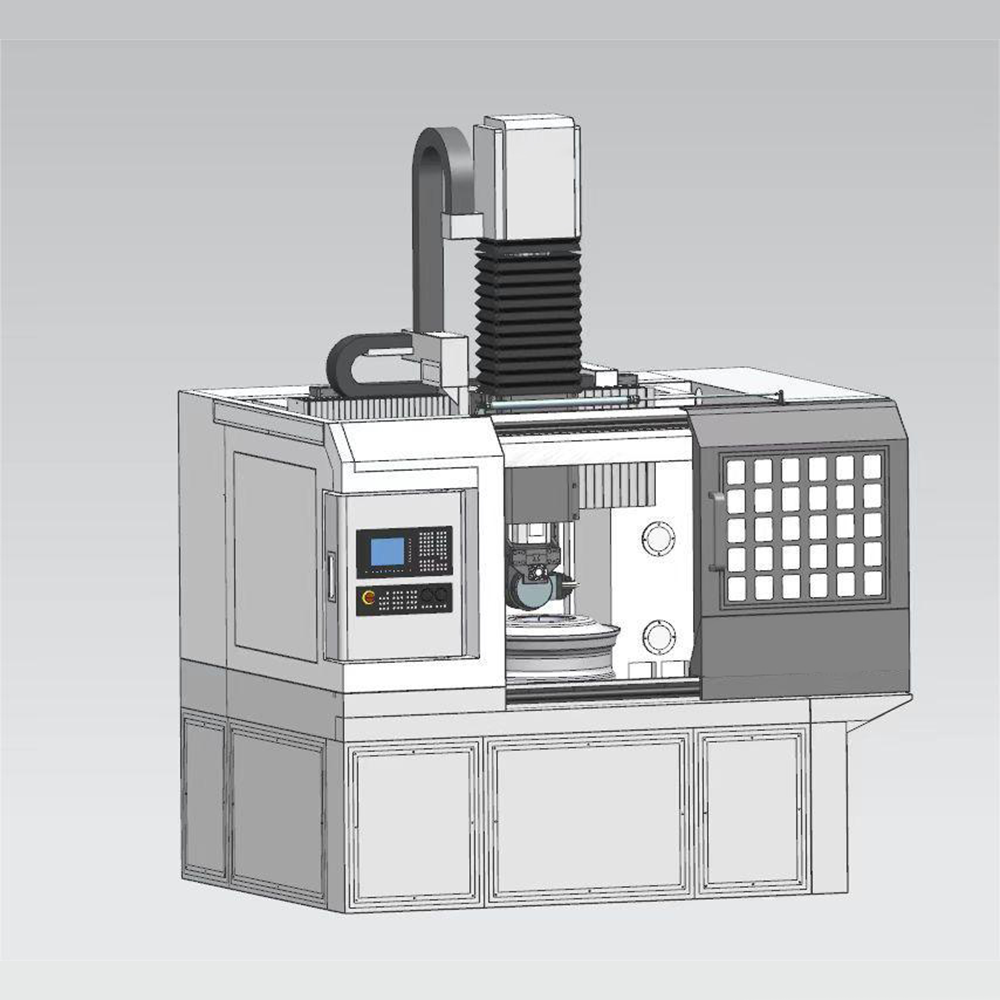

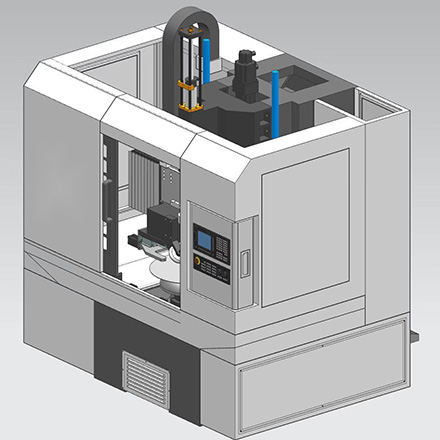

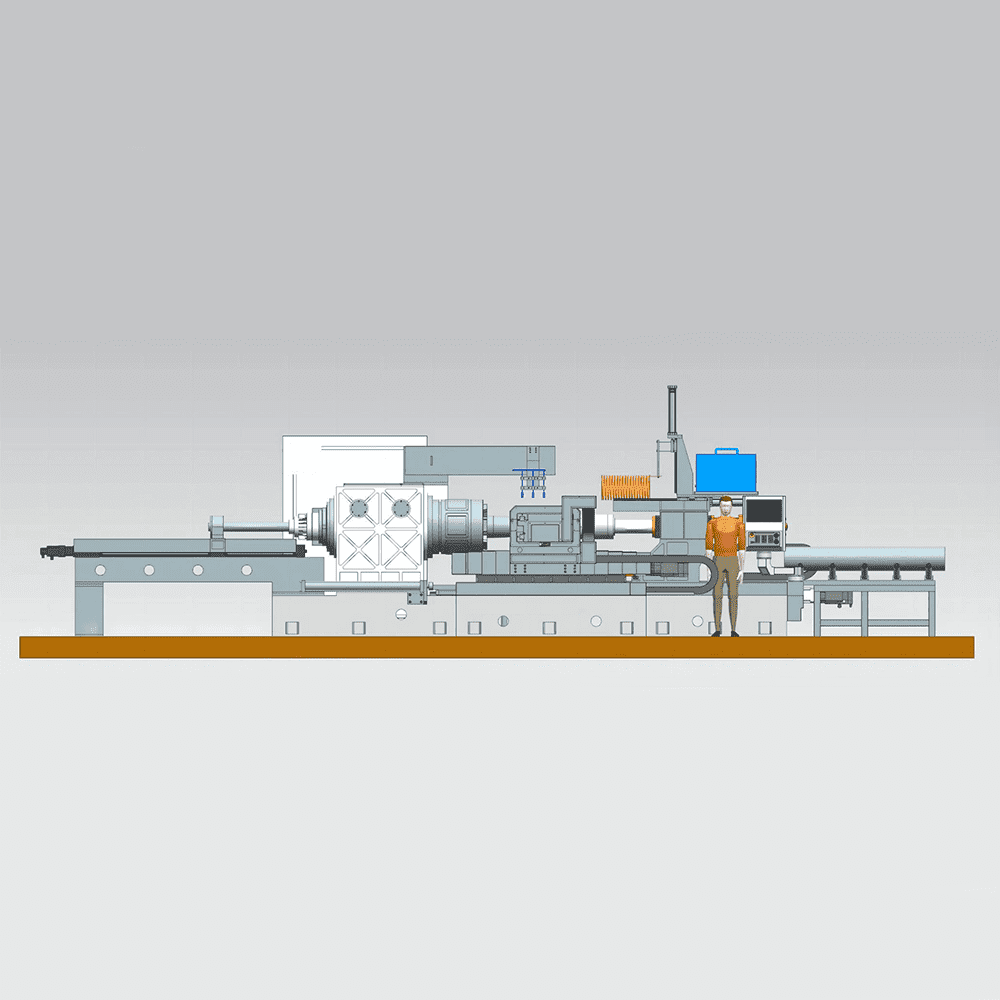

AC-700/2 aluminum alloy hub power spinning machine is specially designed for aluminum alloy hub and rim spinning. The vertical combined structure adopts high-strength castings to ensure the stability of the hub produced by the flow forming process of the machine.

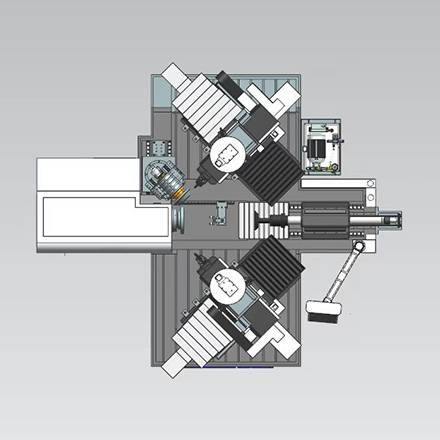

Mechanical design of Aluminum Alloy Hub Powerful Spinning Machined

The transmission mode of this machine is that the horizontal slider adopts a servo hydraulic control system, which has large thrust, high precision and stability. It replaces the previous servo motor screw transmission structure and has better performance. The spindle adopts a large thrust roller bearing, which runs smoothly and powerfully, and adopts an oil cooling structure to maintain the best operating state. The hydraulic control system adopts the German 4WRPEH10 servo proportional valve control, which is highly efficient and reliable.

System control of Aluminum Alloy Hub Powerful Spinning Machined

The equipment adopts Siemens 820D SL system control, which has high precision and convenient programming. It adopts program control mode and can realize manual, semi-automatic and fully automatic operation modes.

Customized high precision CNC spinning machine video

Main functions of Aluminum Alloy Hub Powerful Spinning Machined:

- Spindle adjustability: The spindle can be adjusted and programmed steplessly.

- Radial X-axis feed adjustment: The radial feed of the spinning wheel can be adjusted and programmed steplessly.

- Axial Z-axis feed adjustment: The axial feed of the spinning wheel can be adjusted and programmed steplessly.

- Tail top hydraulic control: The tail top speed is hydraulically controlled, which can quickly approach and gradually decelerate to reduce the impact force that damages the spindle.

- Unloader: The spindle is equipped with an unloader mechanism to facilitate demoulding and removal after the hub spinning is completed.

| Project | Name | Unit | Parameter range |

| Processing capability | Range of machined hub diameters | English time | 14-26 |

| Spindle |

Servo spindle total power Spindle Revolution Spindle interface Tailstock spindle interface |

KW R/MIN DIN DIN |

150 50~800 variable speed DIN 55027 SIZE 15 DIN 55027 SIZE 8 |

| Roller |

Number of rotors Wheel diameter Maximum throat depth Roller mounting interface |

Of the project MM MM DIN |

2 380~400 60 DIN SIZE-6 |

| Spinning thrust |

The lateral thrust of the rotary wheel Wheel longitudinal thrust |

KN KN |

250 * 2 250 * 2 |

| The wheel moves |

Rotary wheel transverse machining speed Rotary wheel longitudinal machining movement speed The wheel advances the speed of movement laterally Rotary Wheel Longitudinal Fast Forward movement speed |

MM/MIN MM/MIN MM/MIN MM/MIN |

Max. 2000 * 2 Max. 2000 * 2 Max. 5000 * 2 Max. 5000 * 2 |

| Roller power |

Wheel lateral power Wheel longitudinal power |

Hydraulic Hydraulic |

Max. 20Mpa*2 Max. 20Mpa*2 |

| Roller stroke |

Wheel travel (X) Wheel’s longitudinal travel (Y) |

MM MM |

250 * 2 500 * 2 |

| Roller positioning |

Wheel lateral positioning accuracy Rotary wheel longitudinal positioning accuracy |

MM MM |

0.015 0.015 |

| Tailstock |

Seat travel Seat thrust |

MM KN |

700 100~250 |

| Hydraulic station |

Rated working pressure Hydraulic power |

MPa KW |

20 90 |

| Oil-cooled | Rated power | KW | 18.2 |

| Center distance | Center distance between top and bottom spindles | MM | 1460 |

| Return |

Spindle unload thrust Spindle discharge stroke |

KN MM |

50~200 100 |

| Equipment | Weight | Tons | 26 tons |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Aluminum Alloy Wheel Hub Powerful Spinning Machine in our production facility for several months now, and we are extremely pleased with its performance. The machine’s precision and stability have significantly improved our wheel hub production process.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

It offers excellent control over the spinning operations, resulting in consistent and high-quality wheel hubs. We highly recommend this machine to any automotive manufacturer looking for advanced spinning technology.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

Our company supplies aluminum alloy wheel hubs to various automotive manufacturers, and the Aluminum Alloy Wheel Hub Powerful Spinning Machine has been a game-changer for us.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The machine’s servo hydraulic control ensures exceptional precision and stability during the spinning process, resulting in wheel hubs that meet stringent industry standards. Its versatility and compatibility with different aluminum alloy materials have expanded our product offerings, giving us a competitive edge in the market. This machine has significantly improved our production efficiency and overall business performan