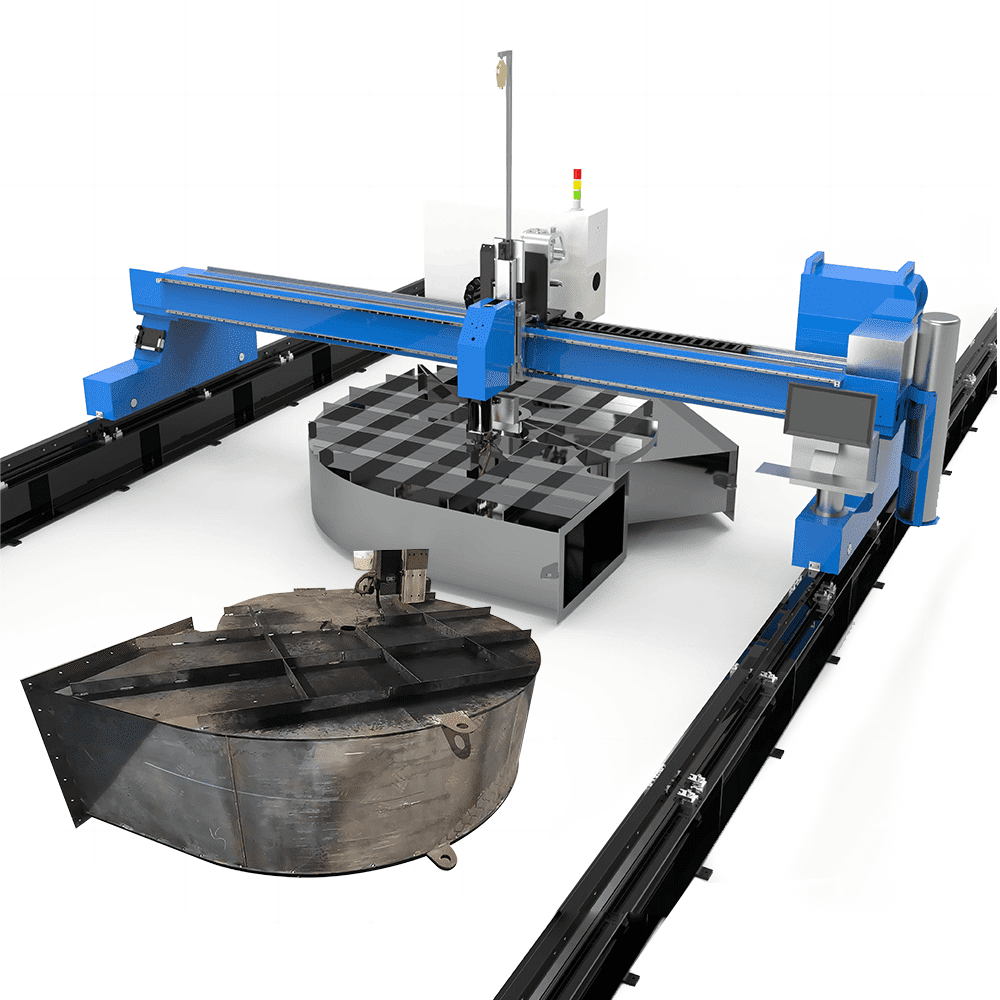

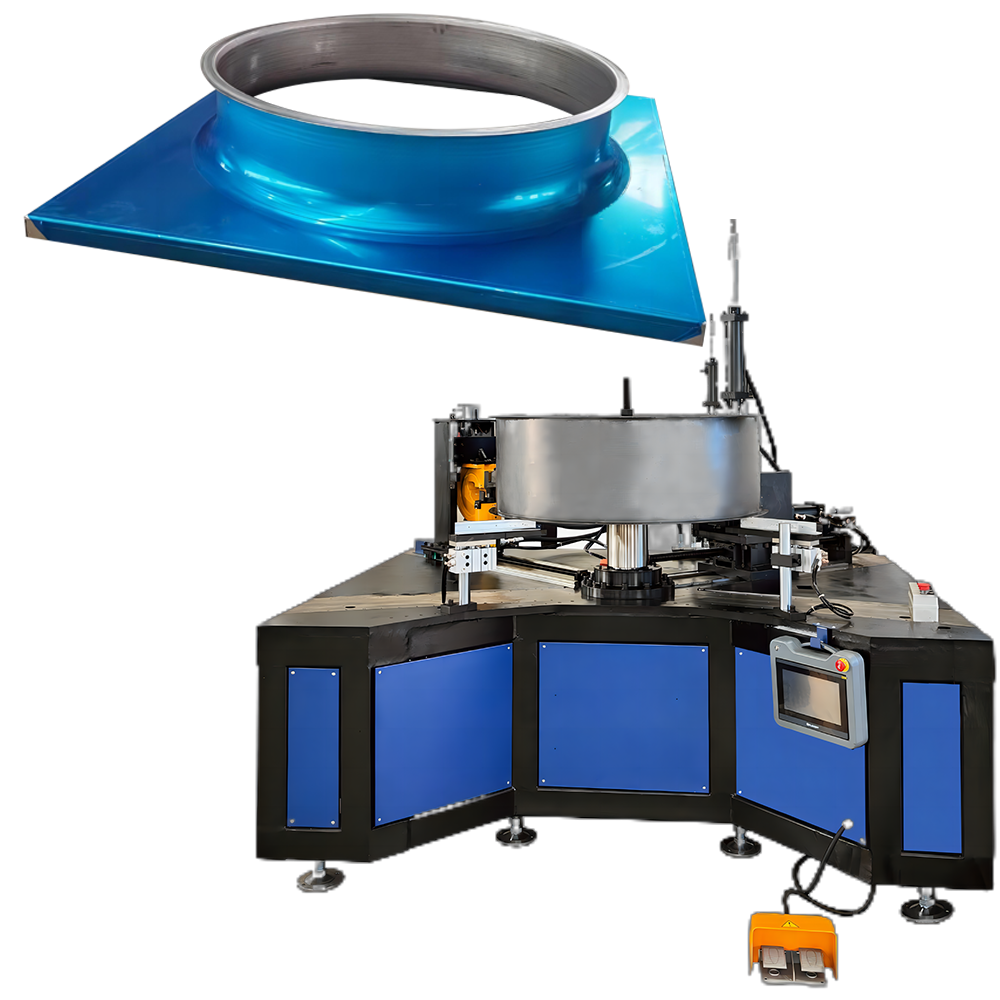

Gantry Stiffener Auto Vision Welding Machine

|

Machine Name |

Gantry Welding Machine |

|

Model |

AC LMH |

|

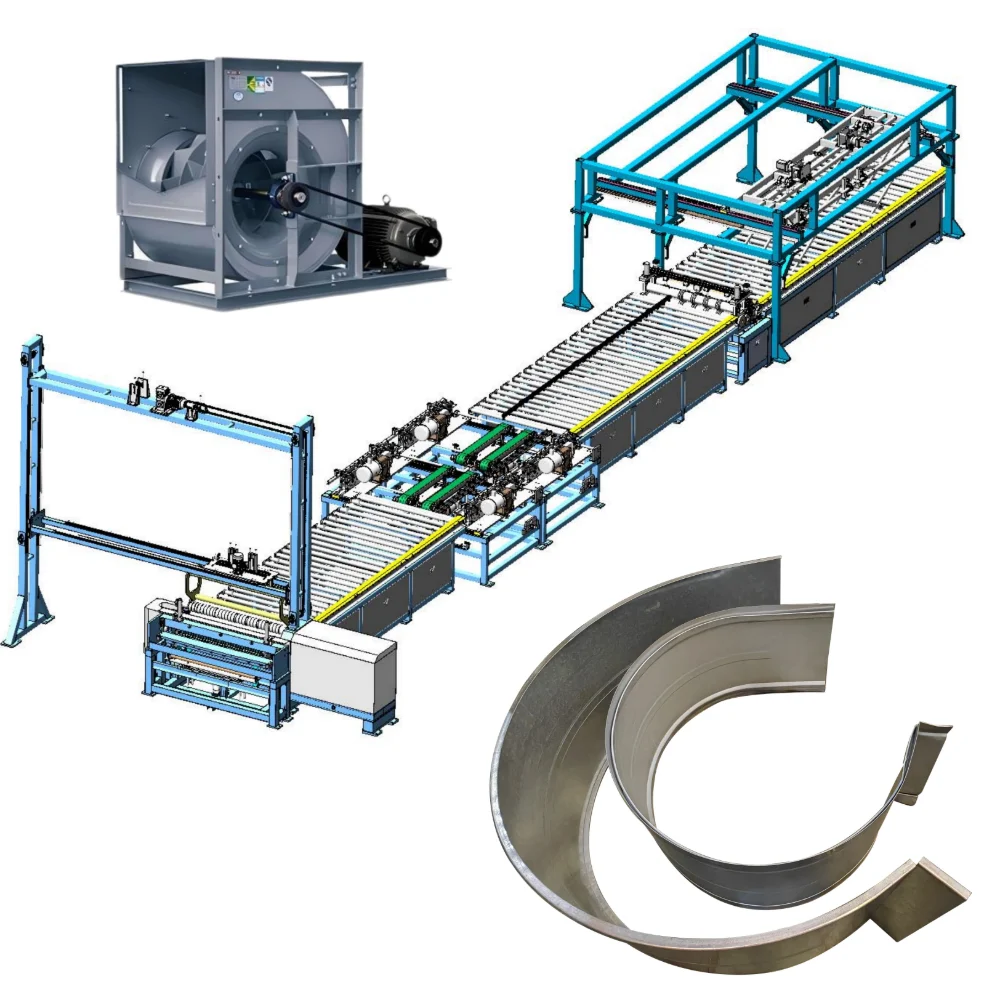

Application Industry |

Industrial fan housing, Sheet metal |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

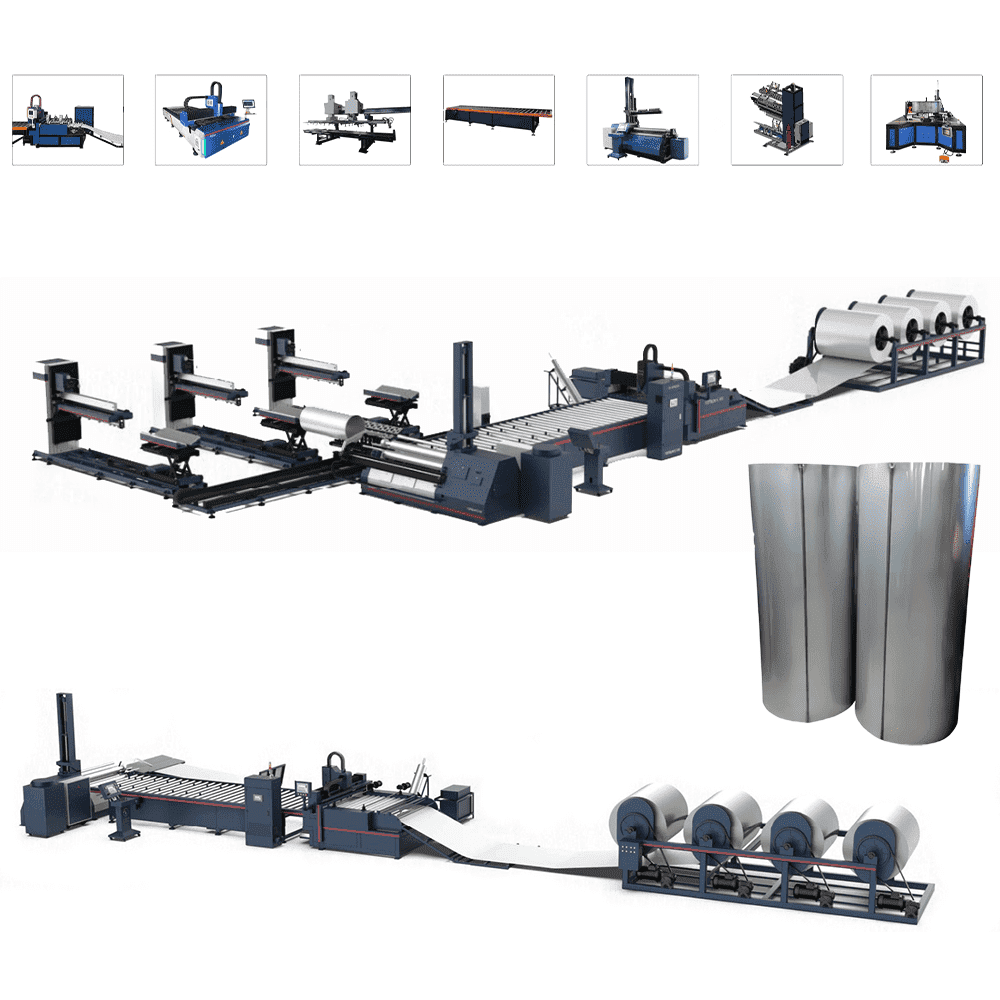

Automatic welding A-Z Project:

1 Centrifugal fan housing vertical welding machine 2 Centrifugal fan casing horizontal welding machine 3 Robot AI welding machine, 4 Gantry welding, 5 Laser welding,

- DETAILS

- PARAMETERS

- CUSTOMER TESTIMONIALS

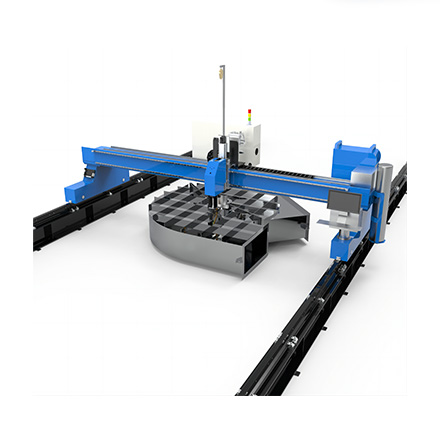

Altron centrifugal fan gantry reinforcement automatic welding machine is a highly efficient automated solution designed for welding side panels and reinforcements, such as large industrial centrifugal fans, high-pressure fans, and shells with high strength requirements for shell parts!

The machine is designed to simplify the welding process, improve productivity and ensure high-quality welding. The gantry structure greatly reduces the waste of space area.

Gantry Welding Of Industrial Fan Housing Reinforcement

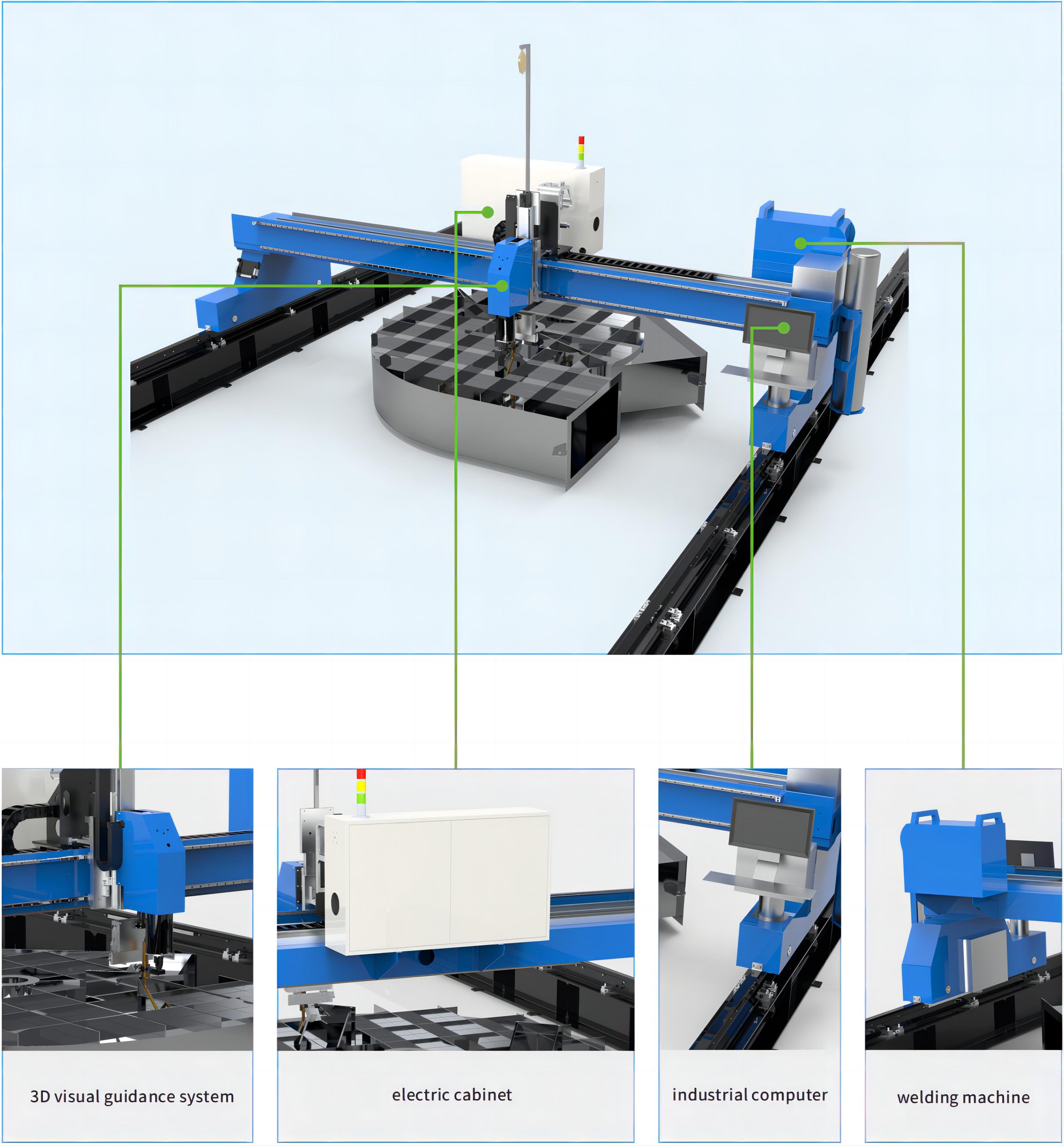

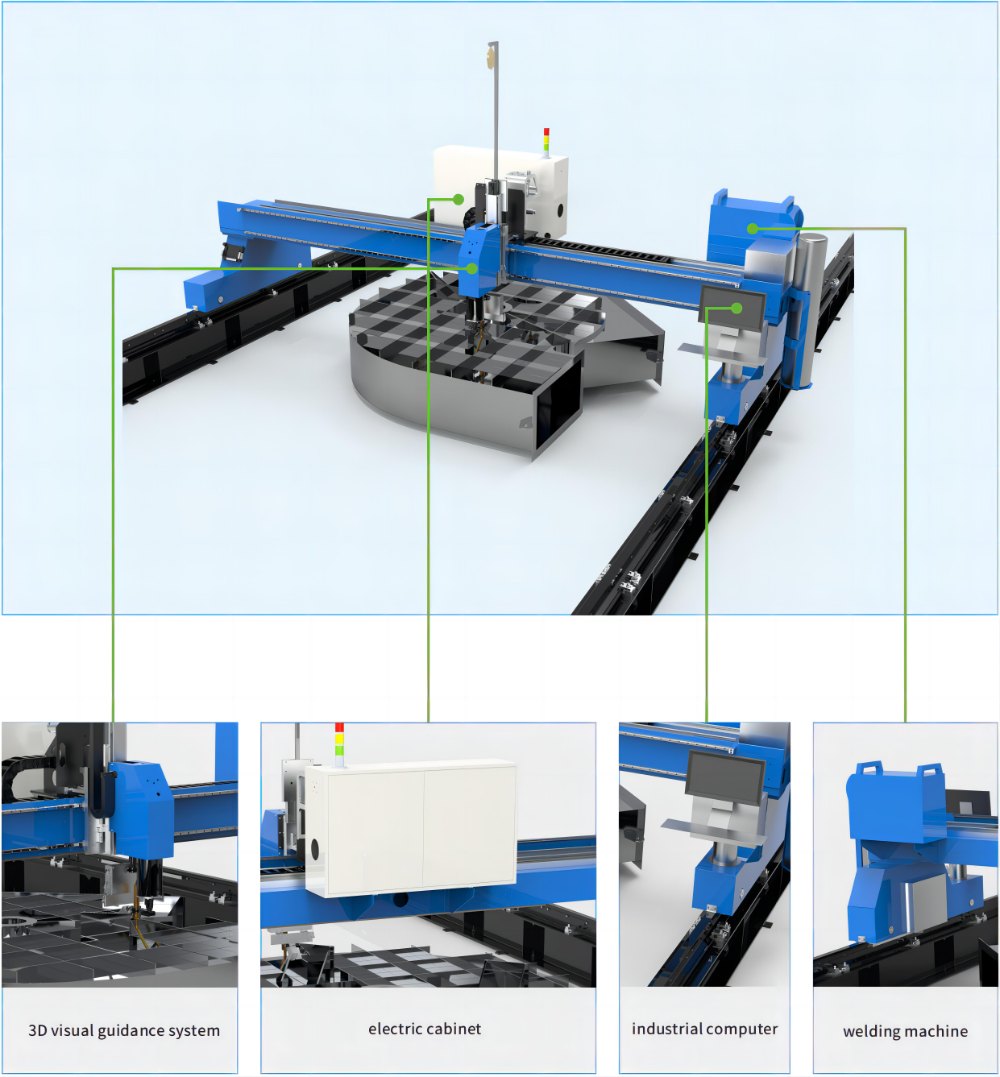

Gantry Welding Machine Structure

Equipment composition: gantry + 3D visual guidance system + electrical cabinet + industrial computer + electric welding machine

The gantry stiffener automatic welding system consists of several key components that enable its efficient operation. These components include the five-axis servo control system, PLC logic control system, visual positioning system, welding machine system, gun cleaning system, and welding smoke purification system.

How to Use Gantry Welding

The gantry stiffener automatic welding system is a solution that addresses the limitations of traditional manual welding methods by integrating advanced technologies. Comprising the five-axis servo control system, PLC logic control system, visual positioning system, welding machine system, gun cleaning system, and welding smoke purification system, this system offers several key advantages.

One significant benefit is the automation of data collection. The system automatically gathers information for each stiffener welding node from the CAD layout and product calibration. This ensures accuracy and reduces the potential for errors in the welding process.

To minimize welding distortion, the system allows workers to select the welding sequence and procedure flexibly. This customization capability enhances the overall welding quality and ensures that specific requirements for each welding node are met.

3D Vision System For Gantry Welding

Advantages of Gantry Stiffener Auto Welding Machine:

- High Production Efficiency and Cost Savings: The automatic equipment significantly improves production efficiency, reducing the need for manual labor and saving on labor costs.

- Universal System with Flexibility: The system supports the importation of new product drawings, allowing for flexible adjustment of welding-related parameters to accommodate different requirements.

- High-Quality Welding and Aesthetic Appearance: The automatic equipment ensures beautifully formed welding seams with high welding quality, minimizing the need for additional grinding or finishing.

- Flexible Work Scope: The system can be configured to accommodate various solder sizes or work site conditions, providing flexibility in its applications.

- Fully Automatic Intelligent Welding: The integration of intelligent welding technology enables fully automatic operation, enhancing the overall image and reputation of the company.

- 3D Visual Imaging System with Wide Range: The equipment incorporates a 3D visual imaging system that enables a wide range of photographing capabilities. This system allows for flexible placement of the solder, ensuring precise and accurate welding.

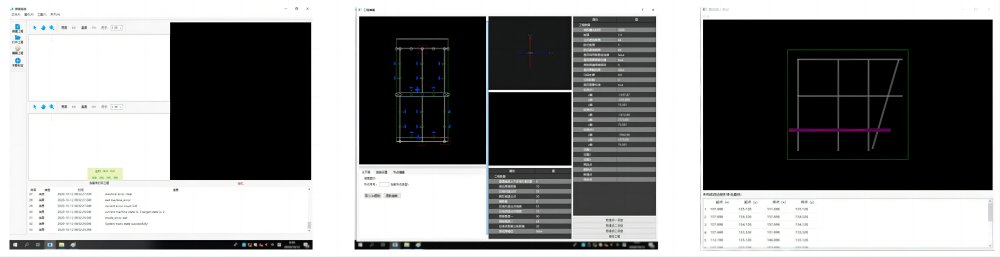

Gantry Welding Operation Interface Diagram

Import the corresponding CAD drawings on the computer of the gantry welding machine, and edit and modify the drawings. You can also set the welding process parameters in the host computer, and save the imported project after setting. Subsequent welding processes can be directly called according to the product type without repeated settings, which is simple and easy to use.

Welding Effect

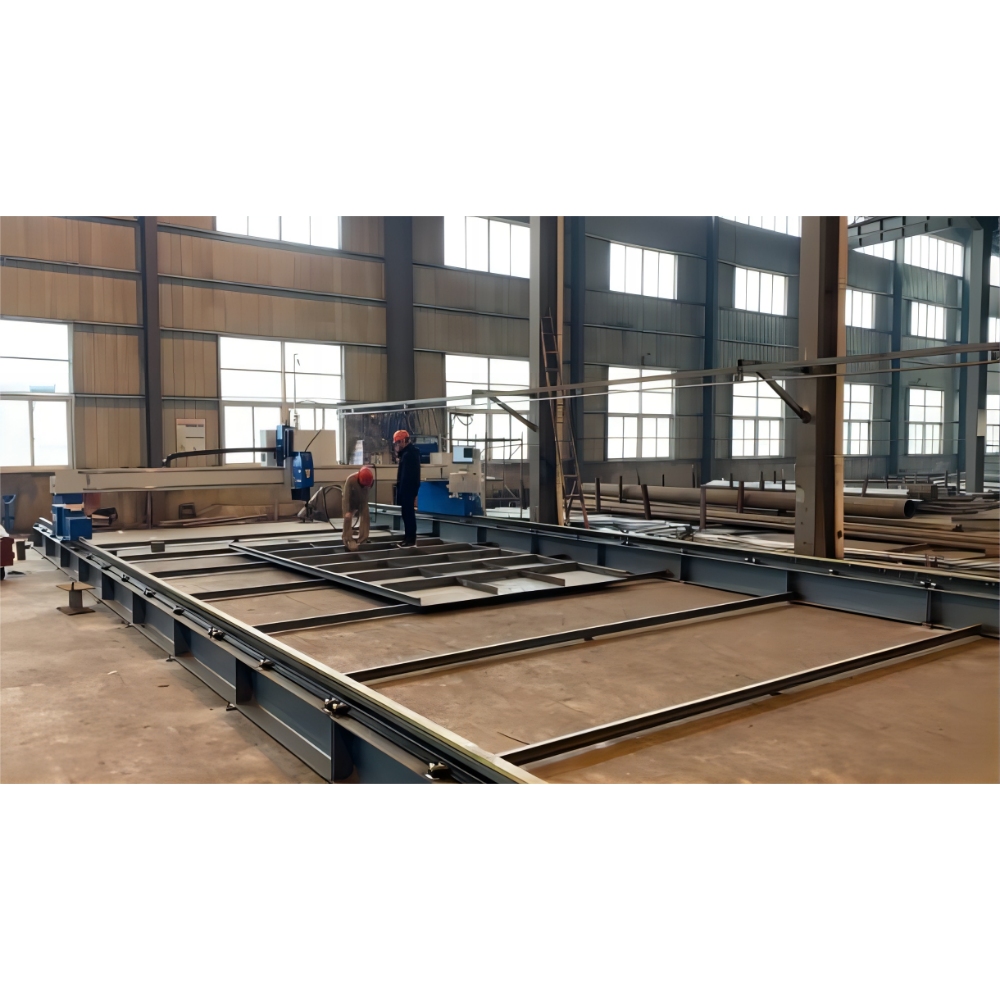

The length and width of the gantry can be customized according to the customer’s industrial fan production process, and multiple workstations can be set within the gantry’s travel range!

According to the design of the industrial centrifugal fan housing, whether to weld the reinforcement first or weld after forming, the temperature needs to be controlled during the welding process to prevent overheating and deformation during the welding process!

Configuration

Parameters Of Gantry Welding:

- Parameter Length: The total length of the track ranges from 10 to 20 meters, with the option for customization beyond this range.

- Width: The total equipment width is available in options of 4m, 5m, 6m, or 7m.

- Height: The equipment has a height of 3 meters.

- Quality: The device has a weight capacity of 5 tons (excluding the track).

- Product Length: The product length should be less than the total track length minus 2 meters, and the product width should be less than the total width of the equipment minus 1.2 meters.

Equipment Power Supply: The power supply for the equipment is AC380V, and the welding machine is also powered by AC380V.

Applications of Gantry Auto Welding Machine

Sheet metal structure welding site

Industrial centrifugal fan casing welding site

Gantry Stiffener Automatic Welding Equipment

| Item | AC LM01 / AC LM02 |

| Length | Full length of track 10-20 meters, out of range support customization |

| Width | Total width of equipment 4M / 5M / 6M / 7M |

| Height | 3.2 Meters |

| Machine Mass | 5 T (not include track) |

| Applicable Product Size | Product length < total rail length – 2 meters; Product width < machine width – 1.2 meters |

| Power Supply | Equipment: AC380V; Welding M/C: AC380V |

Camera Parameters

| Maximum scanning speed | 13.5FPS |

| Data resolution (megapixel) | 0.2 |

| Central object distance | 420 |

| Standard field of view XY(mm) | 220×160 |

| Standard depth of field Z(mm) | ±60 |

| Data interface | USB3.0 |

| Working voltage(V) | 24 |

| Working current (A) | 5 |

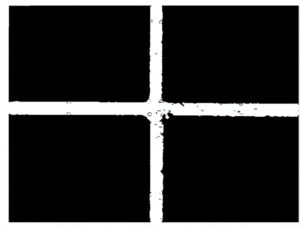

Camera Image

Cross Node Positioning Image

Advantages of Automatic Equipment for Gantry Stiffener

- High production efficiency and labor cost saving;

- The welding seam is beautiful in shape, with high welding quality and no need of grinding;

- 3D vision imaging system, wide photo range, flexible solder placement;

- Universal system, which allows the import of new product drawings and flexible setting of welding parameters;

- The operation range can be set flexibly according to the size of solder or site;

- Fully automatic intelligent welding,greatly improve the corporate image.

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

Upon receiving the machine, I proceeded to watch the training video provided, which proved to be extremely helpful in getting started. The after-sales service was commendable, with patient and helpful assistance throughout the process. Operating the equipment turned out to be straightforward, and I was able to quickly grasp its functionality. Thanks to the simplicity of the operation, I got the machine up and running in no time.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The delivery of the machine was exceptionally fast, which was greatly appreciated. Furthermore, the after-sales service exceeded my expectations with their remarkable level of support. The machine itself has proven to be incredibly efficient, surpassing the speed of other similar machines in the market. I am thoroughly impressed with its performance and the overall experience.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The machine has exhibited exceptional precision, meeting and even surpassing the desired results I aimed for. I am highly satisfied with its ability to deliver the precise outcomes I require. Moreover, the seller’s service has been outstanding. Their prompt response and assistance have been instrumental throughout the process.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The technician’s online guidance and instruction have proved to be immensely helpful, ensuring that I am proficient in operating the machine effectively. I truly appreciate their support and expertise.