Handheld Laser Welding Machine

Laser Welding Machine For Indystal Fans

|

Machine Name |

Handheld Laser Welding Machine |

|

Model |

AC JGW |

|

Application Industry |

Industrial fans, sheet metal, manufacturing |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

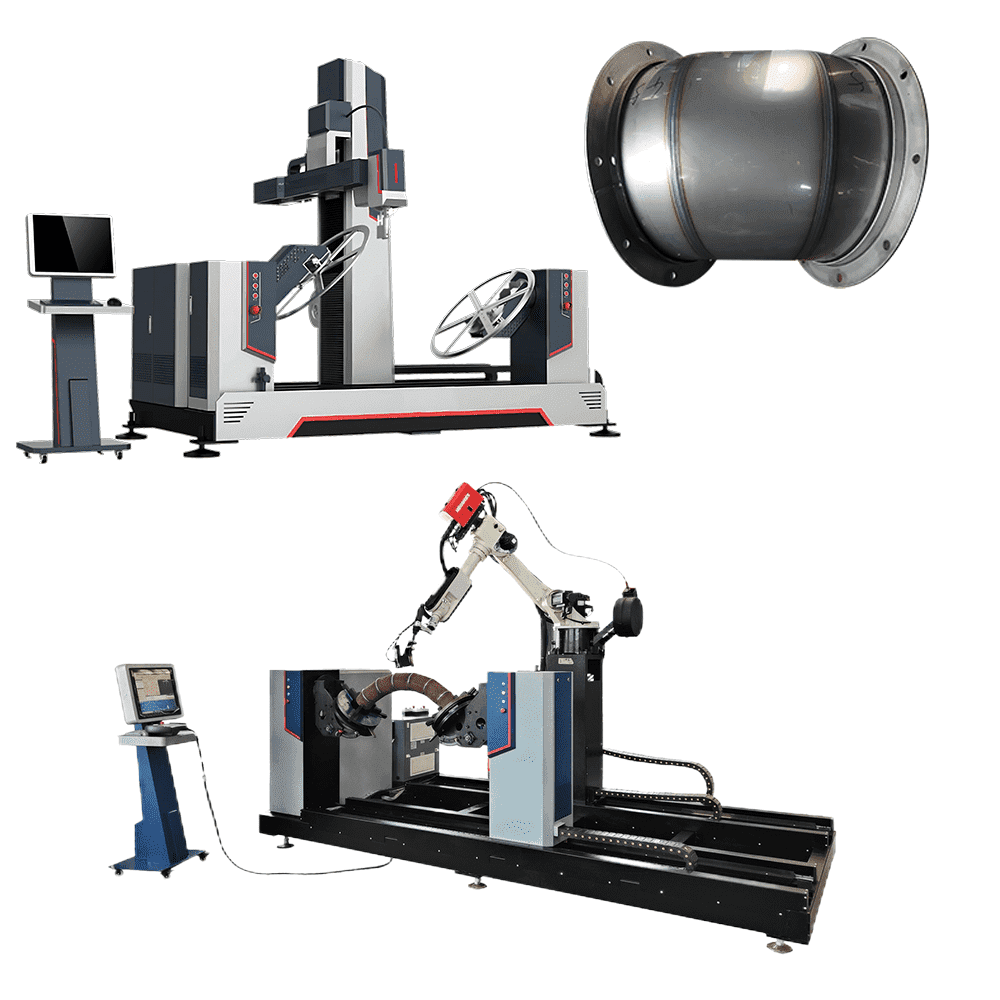

Automatic welding A-Z Project:

1 Centrifugal fan housing vertical welding machine 2 Centrifugal fan casing horizontal welding machine 3 Robot AI welding machine, 4 Gantry welding, 5 Laser welding,

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

The first laser in China, the independently developed wobble welding head features automatic wire feeding. The handheld laser welding machine uses the latest generation of fiber laser to fill the gap in handheld welding in the laser equipment industry. It can be operated with training and certification. It has the advantages of beautiful welds, fast welding speed, and no consumables.

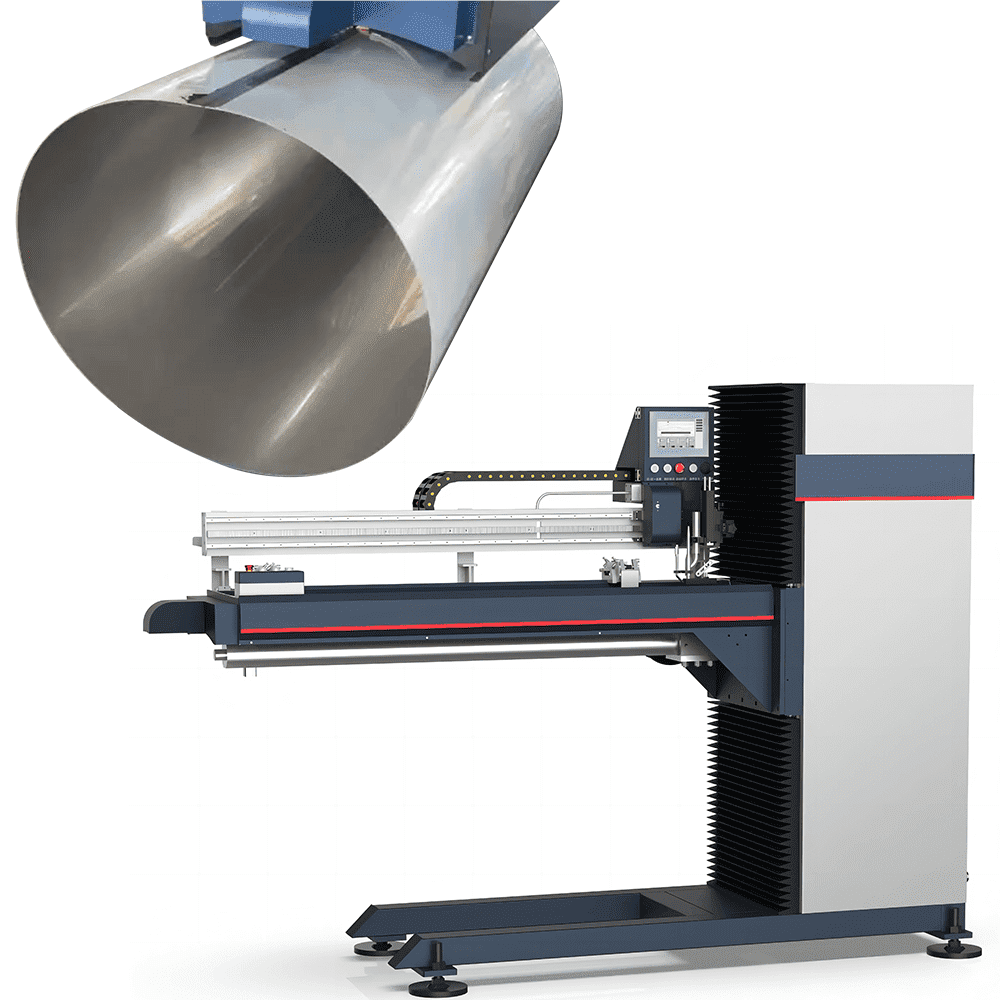

It is suitable for thin stainless steel plates, iron Welding of metal materials such as plates and galvanized sheets.

The handheld laser welding machine can be widely used in complex and irregular welding processes in cabinets, kitchens and bathrooms, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel home furnishings and other industries. With humanized design and technology upgrades, handheld laser welding machines make welders’ work more efficient, safe, energy-saving and environmentally friendly compared to traditional welding equipment. Moreover, the welding speed is 3-10 times faster, saving costs, being stable and worry-free.

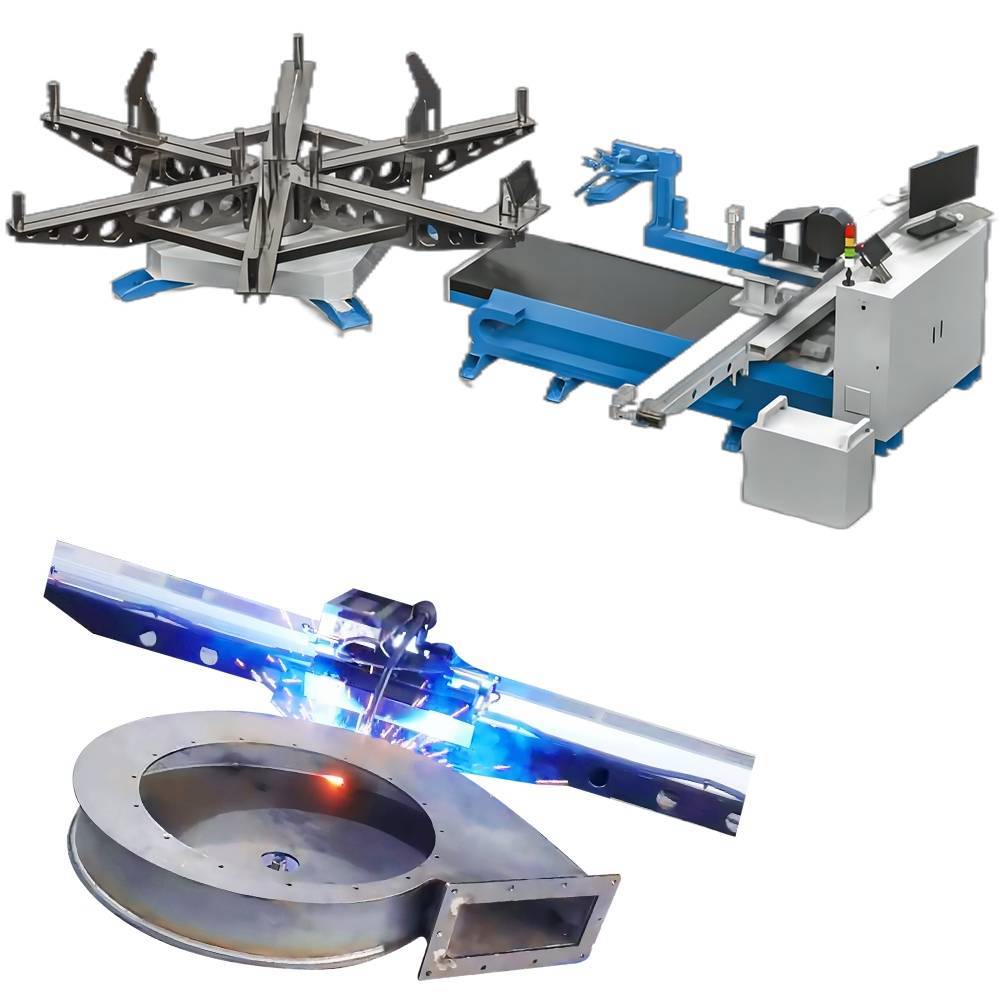

Handheld Laser Welding Process Fan Carbon Steel Parts

Features Of Laser Welding Machine

1 Cost savings: achieved by increasing speed, weakening manual skill requirements, and reducing post-welding processes:

- The speed is 3-10 times that of traditional welding, and one machine can save 3-5 welders;

- Complete the process from learning to proficiency in half a day, without relying on manual skills;

- System control makes the welds smooth and even, reducing the grinding and polishing process.

2.Environmental protection: During the operation of traditional welding machines, welding dust splashes and harmful gases are produced, which is harmful to the environment and workers’ bodies. However, the Minglai laser welding machine has almost zero harm to the environment.

3.Few consumables and long service life: 17 years of experience in laser equipment production and research and development, stable technology, and lifetime after-sales guarantee for the machine.

4.Strong scalability: It can be expanded to configure robots or CNC welding machine tools, and can replace ordinary hand-held heads or swing hand-held heads to meet various welding needs;

5.The hot zone has little impact: the hot zone of laser welding is concentrated, the workpiece has no deformation, no welding scars, and the welding is firm.

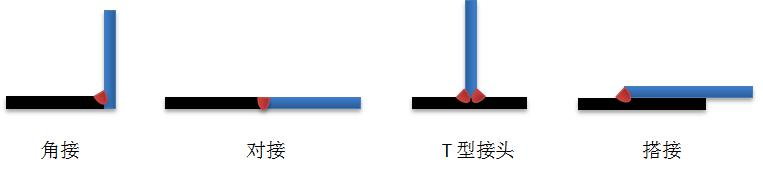

6 Full set of professional welding tips: meet the needs of welding processes such as tailor welding, fillet welding, stack welding, and lap welding.

Configuration

Handheld Laser Welding Sample

Industrial fan metal panel accessories, metal shell accessories, cabinets, kitchen and bathroom, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel furniture, etc…

| Technical parameters·Technical Parameter | ||

| serial number | project | parameter |

| 1 | Laser type | Handheld fiber laser welding machine (domestic model) |

| 2 | Laser power | 1000W, 1500W, 2000W, 3000W |

| 3 | Laser wavelength | 1070NM |

| 4 | Fiber length | Standard configuration: 10M, maximum support: 15M (customized) |

| 5 | Way of working | Continuous/Modulated |

| 6 | Welding machine speed range | 0~120mm/s |

| 7 | Cooling water machine | Industrial thermostatic water tank |

| 8 | Working environment temperature range | 15~35℃ |

| 9 | Working environment humidity range | <70% no condensation |

| 10 | Welding thickness recommendations | 0.5-5mm |

| 11 | Welding gap requirements | ≤0.5mm |

| 12 | Operating Voltage | AC220V/AC380V |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Handheld laser welding in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Handheld laser welding has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now process a wide range of material thicknesses and the machine consistently delivers precise welding results. It has significantly increased our production efficiency and customer satisfaction. We are very satisfied with this investment.