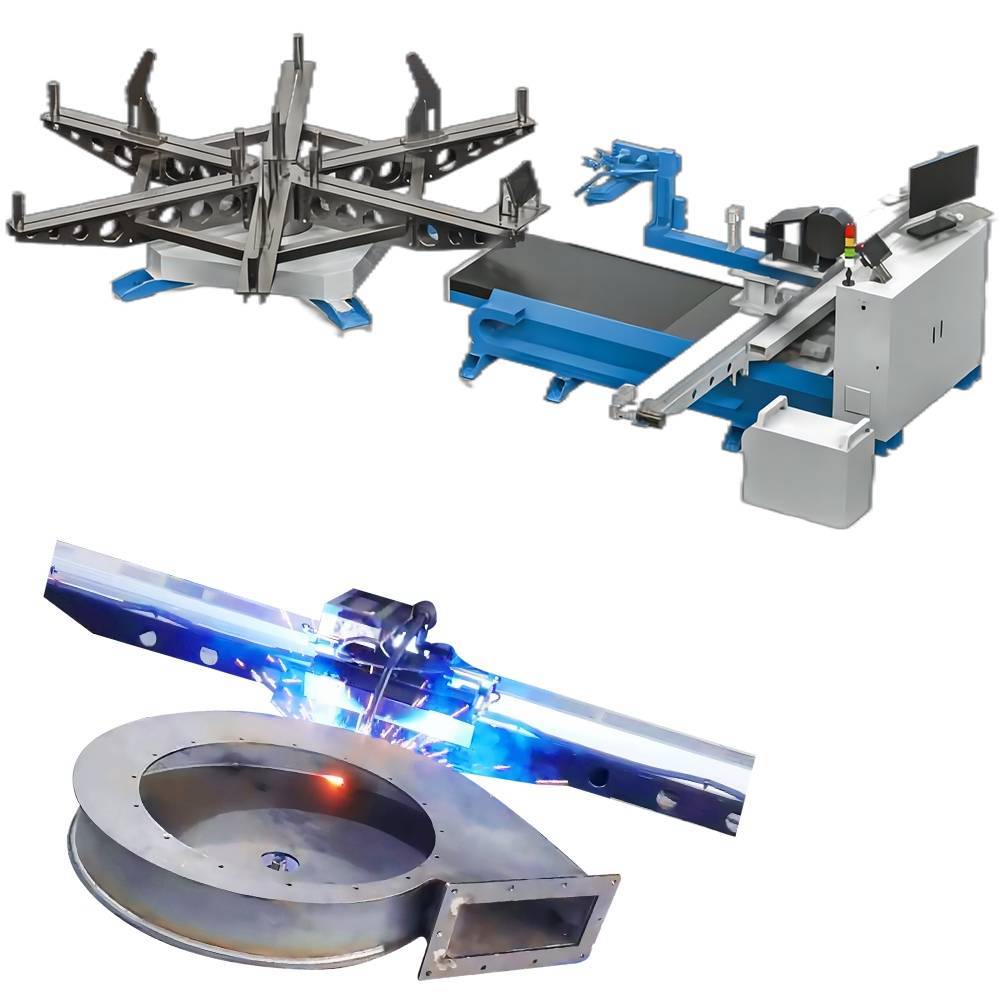

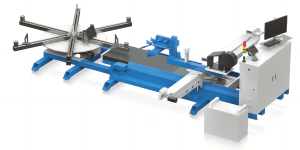

Auto Welding Machine For Centrifugal Fan

Welding for Centrifugal Fan’s Housing

|

Machine Name |

Fan’s Housing Welding Machine |

|

Model |

AC-WK (1500-2000) |

|

Application Industry |

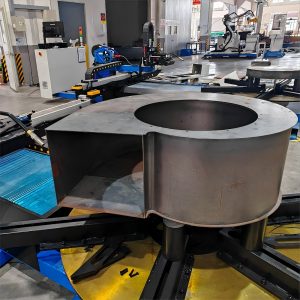

Centrifugal fan’s housing, casing |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

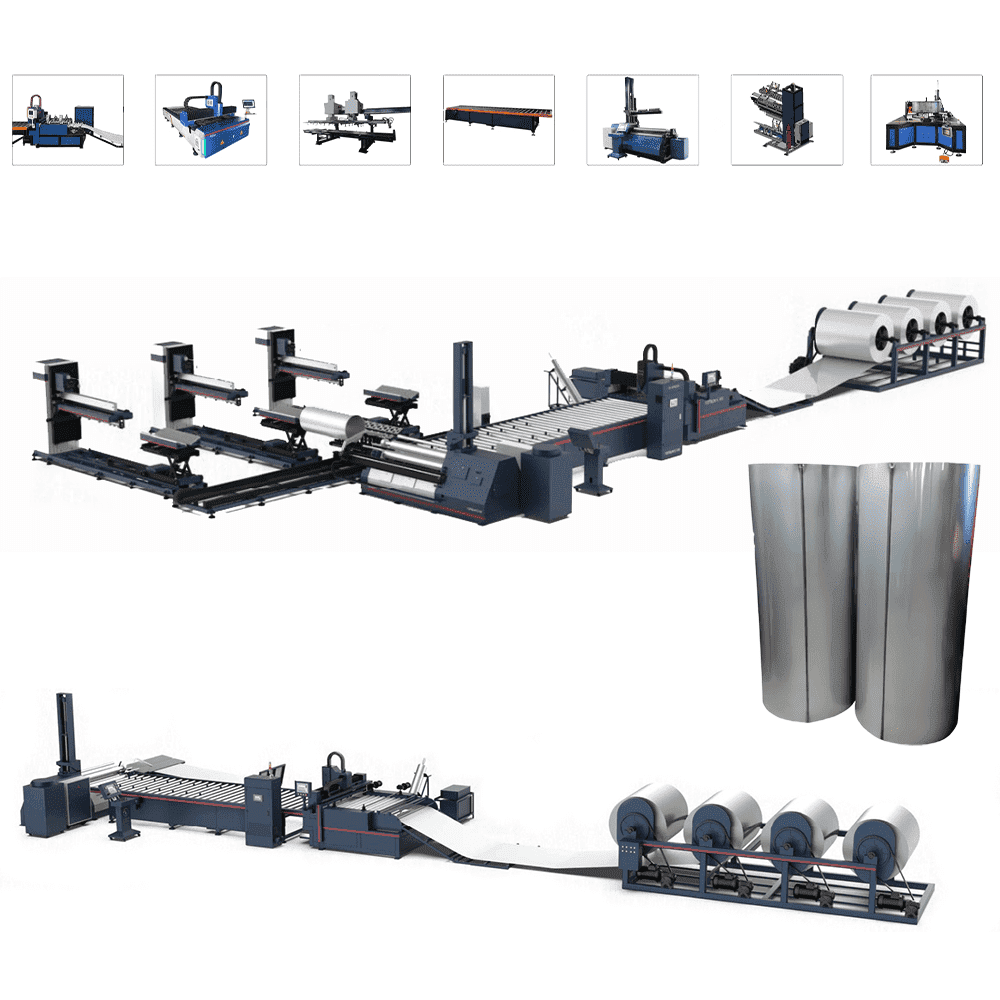

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Automatic welding A-Z Project:

1 Centrifugal fan housing vertical welding machine 2 Centrifugal fan casing horizontal welding machine 3 Robot AI welding machine, 4 Gantry welding, 5 Laser welding,

- INTRODUCTION

- PARAMETERS

- CUSTOMER TESTIMONIALS

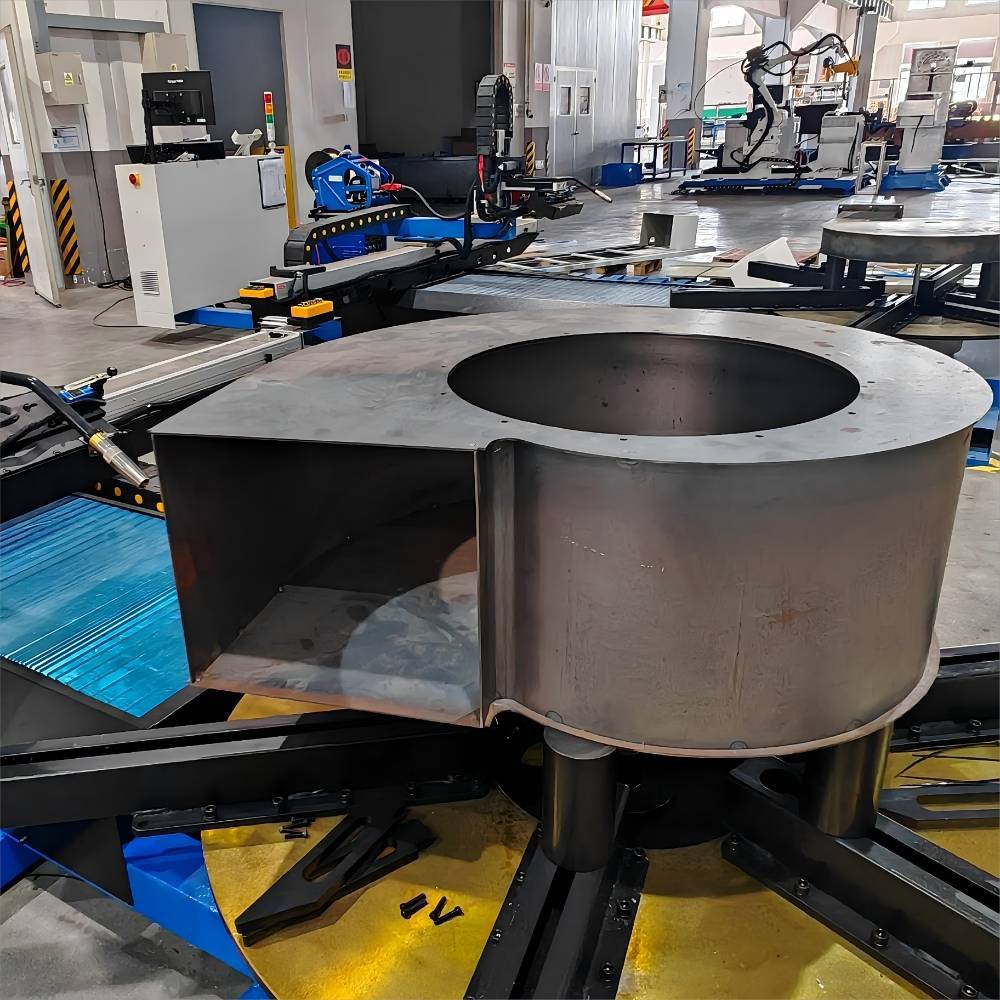

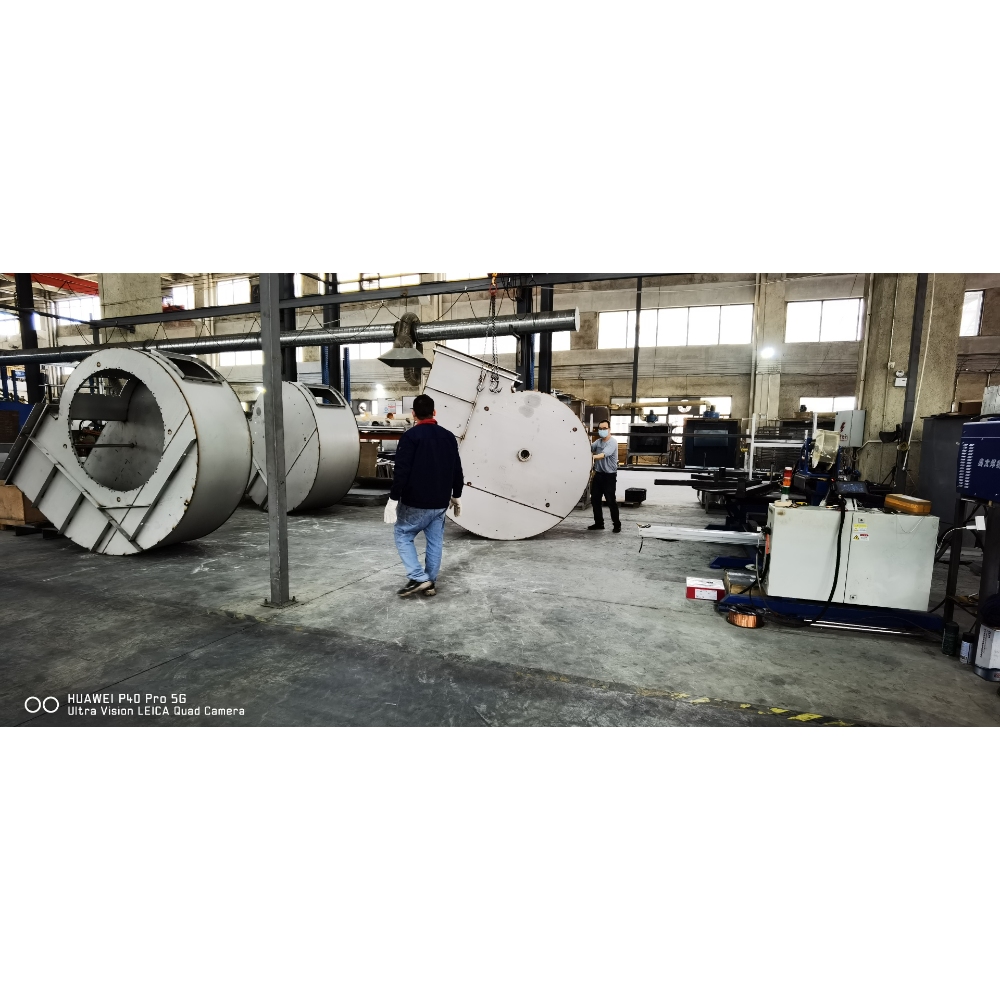

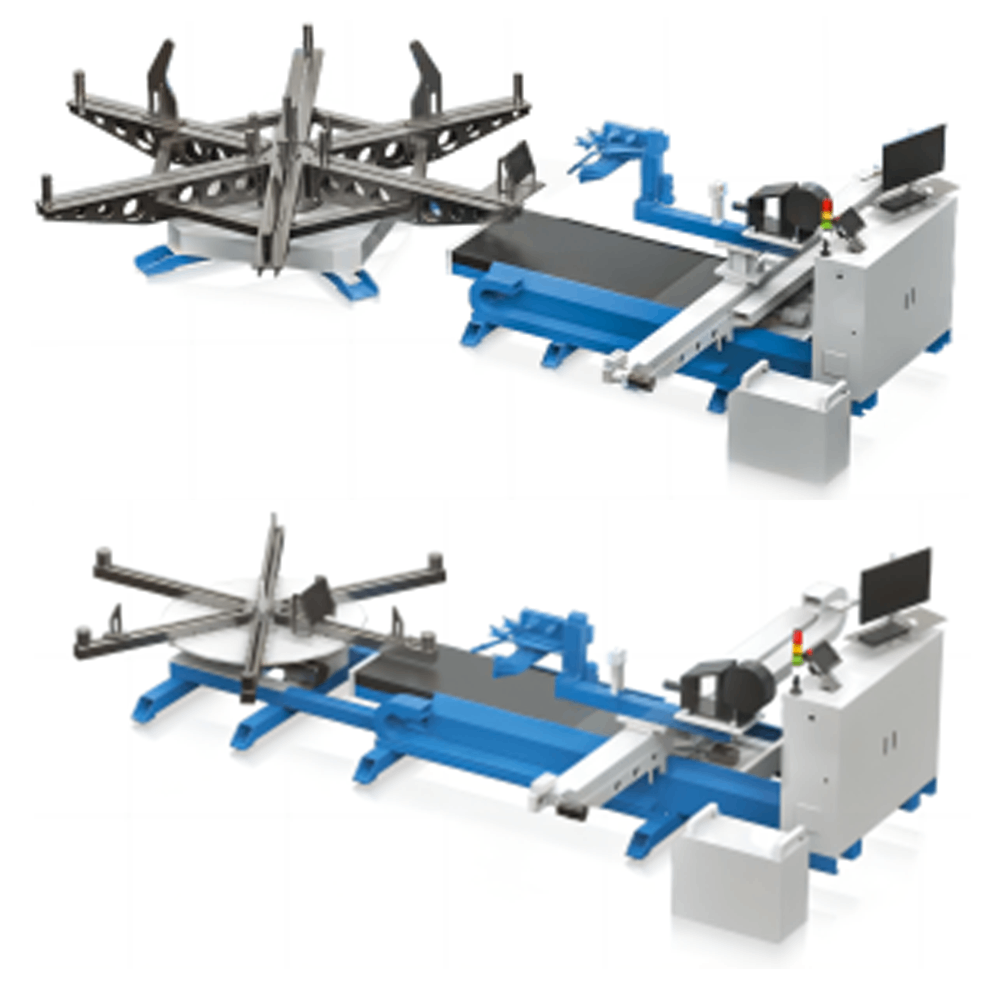

Altron’s welding machine for centrifugal Fans casing can weld centrifugal fan casing within a radius of 2000mm, and the maximum load can reach 2 tons!

It effectively reduces the dependence of industrial fan manufacturers on the technical skills of welding workers. After ordinary workers spot weld and assemble the centrifugal fan casing, they put it on the rotating platform of the welding machine, and the machine’s camera and laser will automatically identify the position of the weld and produce the welding track!

Centrifugal fan housing automatic welding machine brings breakthrough changes to the centrifugal fan industry, making fan welding and manufacturing simple!Altron realizes intelligence, centrifugal fan housing uses laser and visual system to locate welds, and rectangular coordinate manipulators cooperate with positioners to track welding!

Video Of Welding High Pressure Centrifugal Fan

Introduction To Welding Centrifugal Fan Casing

Automatic welding machine designed for centrifugal fan housing. This equipment realizes the automation and unmanned manufacturing of fans, greatly improving the welding quality and efficiency, while reducing the need for labor. The weld is firm and beautiful in appearance, no manual grinding is required, and the time cycle for fan housing powder spraying is shortened!

The welding machine is very easy to operate and does not require a lot of training. The equipment uses a laser machine vision system to automatically find the weld. All welding operations are non-contact and do not generate jitter, ensuring the reliability and beauty of the welding process. This technological advancement of automatic welding equipment for centrifugal fan housings has changed the welding quality and production mode of the industrial fan ventilation industry by realizing automated, efficient and high-quality fan manufacturing.

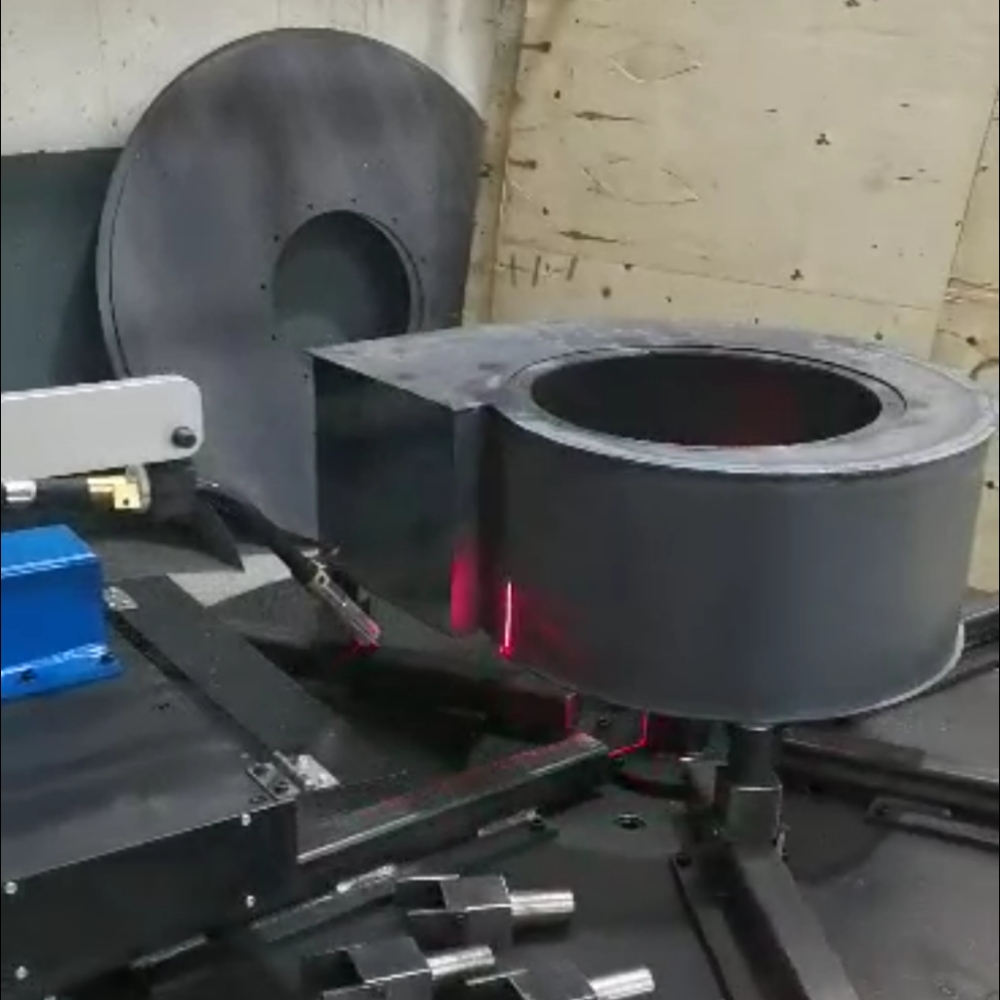

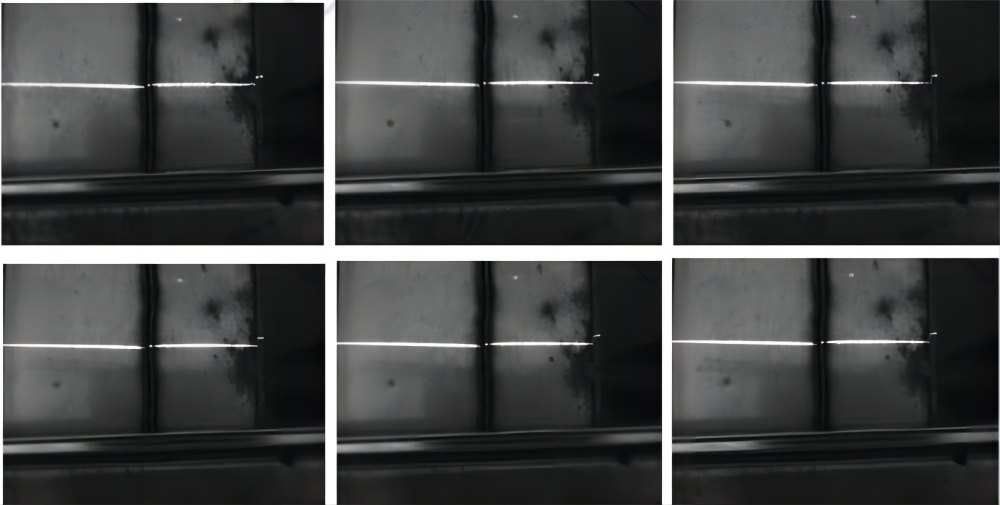

Centrifugal Fan Housing Welding Camera System

The vision system incorporated in the machine represents cutting-edge technology in the field of control. In welding applications, this system adds intelligence and user-friendliness to automatic welding equipment.

Using laser technology, the vision system automatically detects and locates the weld seam’s position, including its front, rear, and height. Even in the presence of irregular Archimedean spiral lines or if the fan shell is unevenly positioned, the visual placement does not hinder the manipulator’s ability to accurately track the weld seam. This ensures precise and reliable welding, regardless of any irregularities or variations in the fan shell’s shape or positioning.

In the process of seam searching, laser light source is used to guide the seam.

Refer to the following figure:

Different welding machines can be replaced to achieve different welding processes, and weld metal materials such as carbon steel, stainless steel, galvanized sheet, etc!

Comparison Between Auto Welding & Manual Welding Of Centrifugal Fan Housing

AutoWelding Machine Model

| Item | AC WK1500 | AC WK2000 |

| Machine Dimension (L*W*H) |

5600*3100*1700mm | 6500*3600*1700mm |

| Machine Mass | 1.6 T | 2.3 T |

| Radius Of Volute | 100-1500 mm | 800-2000 mm |

| Load | 1 T | 2 T |

| Power Supply | Equipment: AC220V; Welding M/C: AC380V |

Equipment: AC220V; Welding M/C: AC380V |

| Power Motor (not include welder) |

7 KW | 9 KW |

|

|

|

Camera Parameters For Centrifugal Fan Casing Welding

| Resolution | 1280×1024 |

| Frame speed | 88fps, Open Turbo Driver the highest can be reached 184fps |

| Light-sensing chip | On-Semi Python 1300 |

| The type of chip | Global shutter CMOS |

| The pixel size | 4.8μm×4.8μm |

| Chip size | 1/2″ |

| The pixel bit is deep | 8/10 bits |

| Video output format | Mono 8-bit, Mono10-bit |

| Number ofl/Os | 4 GPIO (2 Inputs/2 Outputs) |

| The data interface | GigE |

| Operating temperature | -20°℃~+65℃ |

| Power requirements | +10V~+36V(±10%)orPoE |

| Typical power consumption | 3.8W~4.9W |

Video Of Welding Large Centrifugal Fan

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

Upon receiving the machine, I promptly watched the training video provided and proceeded to start using it. The after-sales service demonstrated exceptional patience and helpfulness throughout the process, assisting me whenever needed.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Operating the equipment proved to be straightforward, and I was able to quickly familiarize myself with its functionality. Thanks to its user-friendly design, I had the machine up and running in no time.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

I am pleased to report that the machine exhibits remarkable precision and fully meets the desired requirements. It is capable of delivering the exact results I need with great accuracy. Furthermore, I am highly satisfied with the exceptional service provided by the seller. The technician’s guidance and online support in teaching me the operation of the machine have been invaluable.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

After three months of using the machine, I am delighted to report that it has consistently delivered excellent results. I am highly satisfied with its performance and the outcomes it has achieved. The machine has proven to be reliable, efficient, and effective in meeting my needs. Based on my positive experience, I have made the decision to purchase another one in the near future. This speaks to my confidence in the machine and its ability to further enhance my operations.