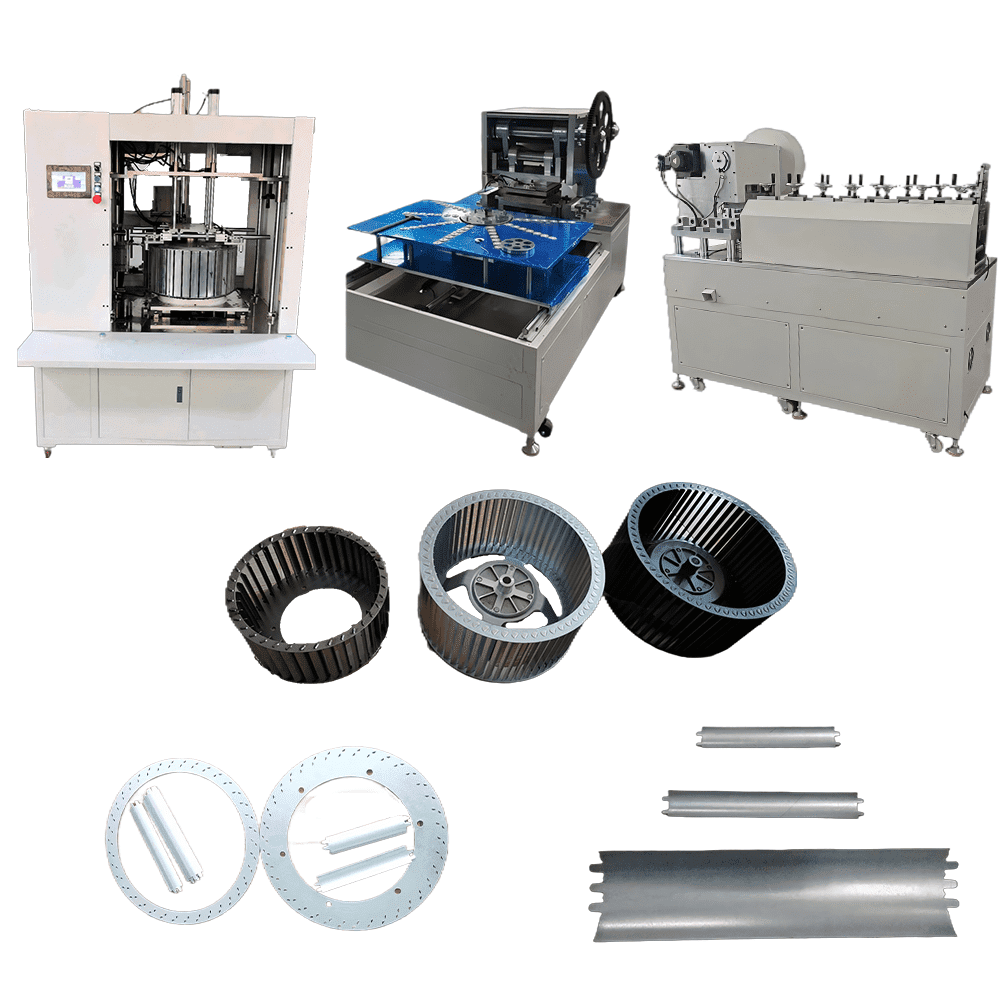

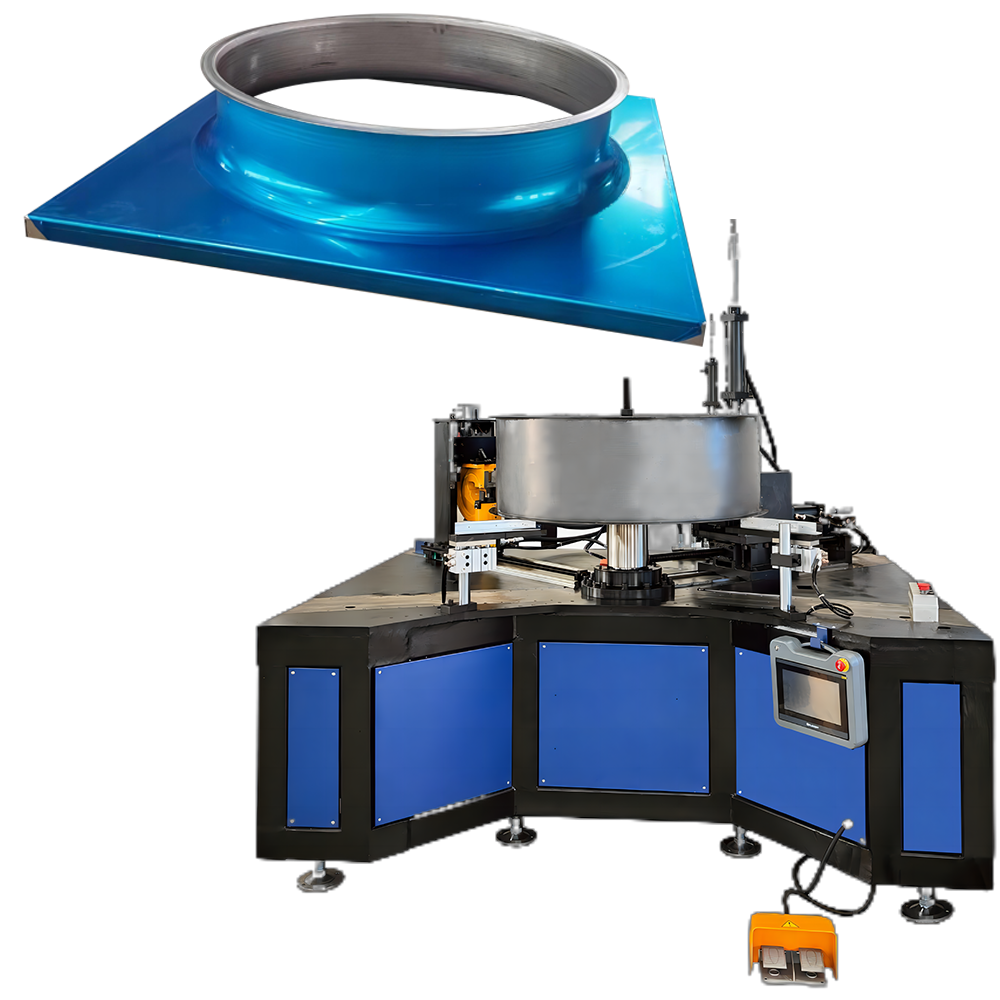

Multi-wing Centrifugal Fan Impeller Forming and Punching Machine

Multi-wing Centrifugal Fan Impeller Forming & Punching

|

Machine Name |

Multi-blade centrifugal fan impeller forming production line |

|

Model |

ACMI-70-1100MM(Multiple Models) |

|

Function |

Forming blades, Stamping parts, Rivets, Rivet inserts. |

|

Material: |

Different metal materials such as aluminum, iron, stainless steel, galvanized sheet; |

|

Technical Guidance |

7*24 Online Service, Engineer Video Online Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Industrial Fans A-Z Project:

1 Centrifugal Fan Housing Forming 2 Industrial Fan Impeller Customization OEM

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Altron‘s a high-tech enterprise dedicated to intelligent automation equipment solutions for industrial fans. It focuses on the mechanical equipment and automated mechanical equipment manufacturing fields of multi-blade impellers, supports customized multi-blade impeller forming solutions, and meets the needs of industrial fan manufacturers.

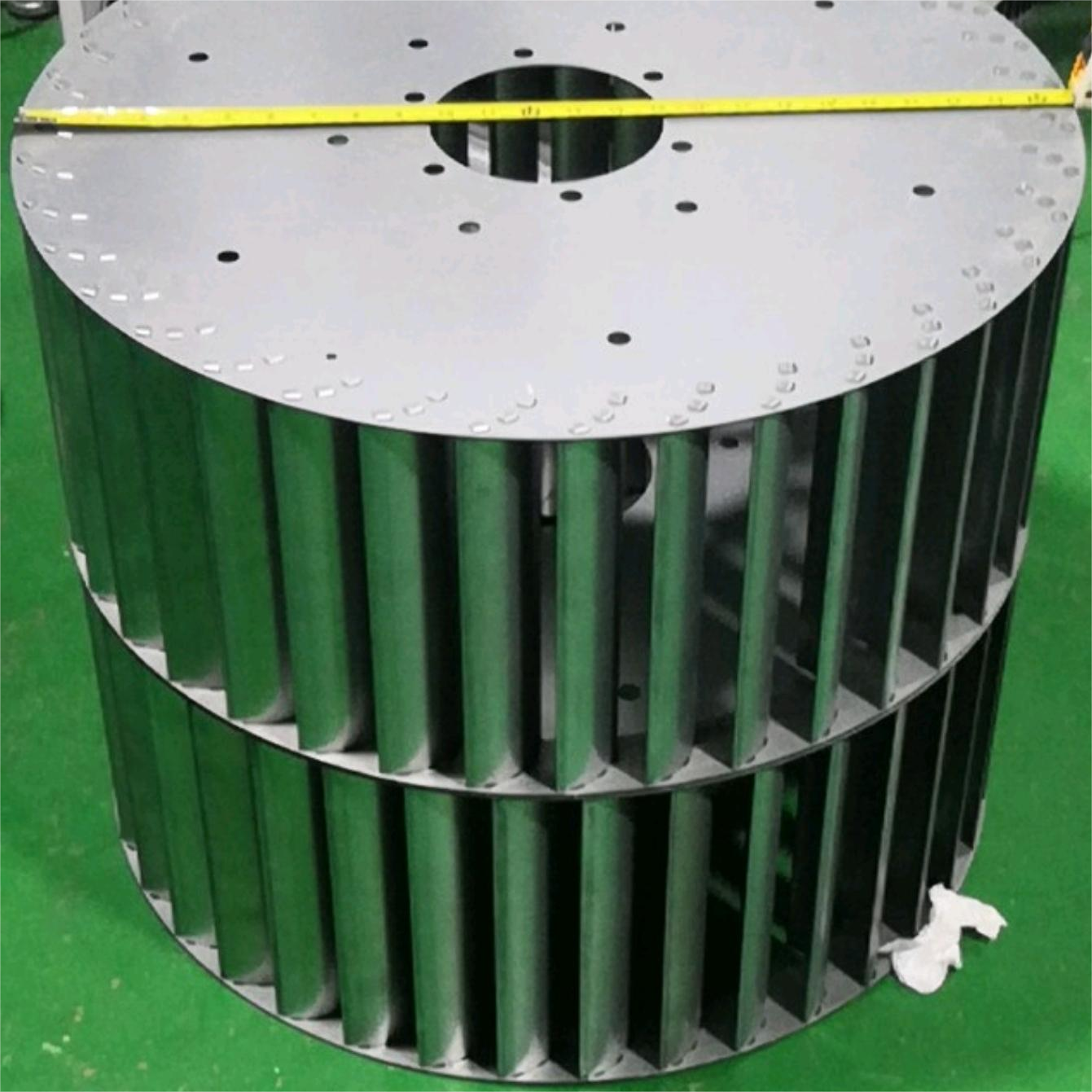

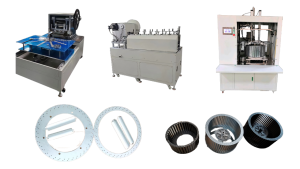

Multi-blade fan impeller automation machine can help factories improve production efficiency by 3-6 times! The machine covers different types of multi-blade impellers with diameters of 40-1100 MM, including stamping, assembly, forming, balancing and other different processes! A continuous automatic production line can be realized.

Altron Automated Multi-Blade Impeller Production Machine

Efficient, safe, energy-saving, environmentally friendly, compatible, and sustainable development, helping ventilation fan industry manufacturers to reduce staff and increase efficiency, and solve the problem of manufacturing automation production upgrades.

Multi-Blade Impeller Automated Production VS Manual

Automatic Production Of Multi-Blade Impeller Forming:

- The blades are loaded by clip-type, which is easy to convey and load quickly;

- Automatically feed the material to the inserting station, servo drive, photoelectric induction, circular equal-division gap movement, to achieve automatic inserting,

- Automatic riveting, adjustable tightness; balanced force

- Professional production line can be made without manual intervention;

The efficiency is extremely high, and the multi-blade impeller with a diameter of 130 can reach 80-120 pieces per hour! It is 4-6 times the speed of manual labor; the machine adopts an enclosed type, and the rotating impeller is separated from the operator, so the safety of production is guaranteed!

Manual Production Of Multi-Blade Impeller Forming;

- Manually insert all the blades of one circle of the impeller into the positioning groove below;

- Use other tools to fix all pages, ropes are used in the picture;

- Make multiple adjustments to make the positioning holes of the upper end cover inserted evenly;

- Manually beat to make the blades evenly stressed;

- The upper and lower rollers of the semi-automatic machine mechanically squeeze the blades;

The efficiency is extremely low, and it is often impossible to align the blades! Due to the thinness of the blades, the operator should operate very small

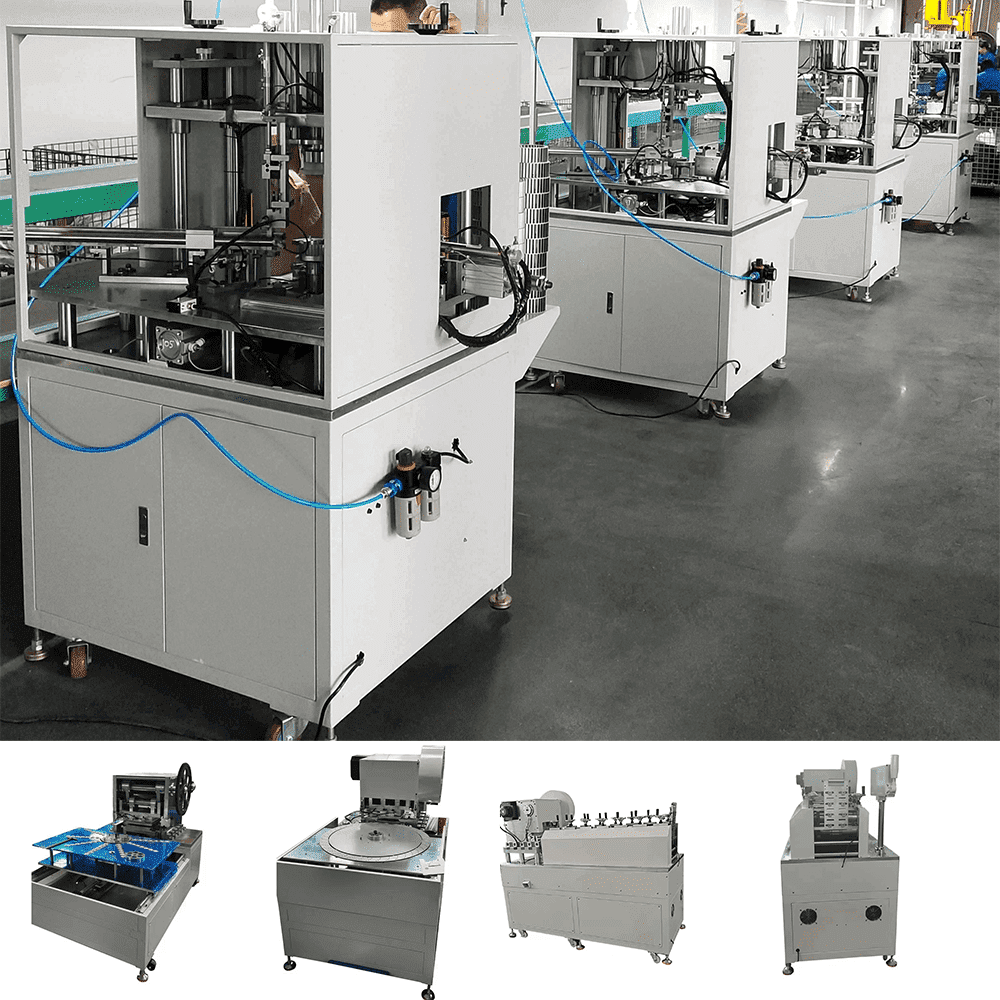

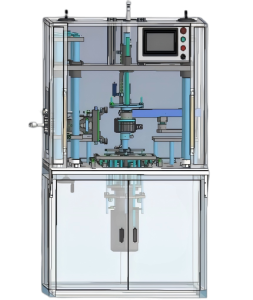

Introduction To Multi-Blade Impeller Forming Automated Machine

- 1.1 The frame is made of high-quality square tube welding and 45 carbon steel inlays. It is fully high-frequency annealed and is solid and reliable.not easy to deform; the bed is surrounded by sheet metal, and the entire surface is chrome plated and spray-painted, making it safe, environmentally friendly, and beautiful.

- 1.2 The blades adopt a magazine-type loading method and are delivered sequentially, making loading convenient and fast.

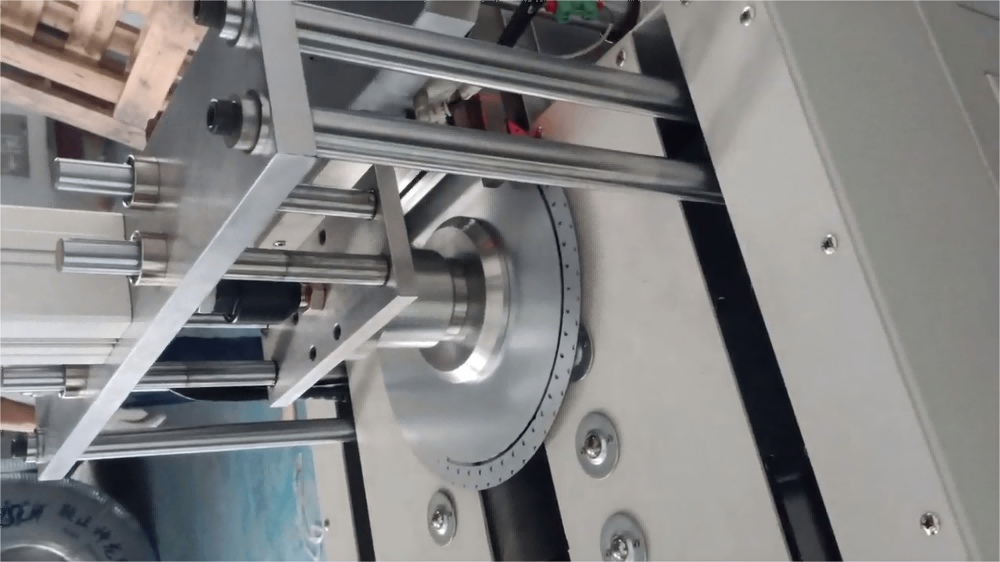

- 1.3 Inserting mechanism: automatically feeds materials to the inserting station, servo drive, photoelectric induction, circumferential gap motion,Automatic blade insertion, accurate and smooth, safe and efficient, stable and reliable.

- 1.4 Riveting mechanism: automatic riveting, adjustable tightness; balanced force, firm fastening, good consistency; dynamic balance test in seconds pass, save time and effort, and ensure quality.

- 1.5 Control system: number of blades, product changeover and direction change, various parameters are randomly adjustable, and the human-machine interface can be repaired in one click change, easy to learn and understand in seconds, simple to operate.

- 1.6 Interchangeable and universal: one machine with multiple models, one machine with multiple uses. Single layer, double layer, multi-functional and compatible with forward wind and reverse wind; not with the same product, you only need to replace the wind wheel end ring fixture and riveting fixture. The height is adjustable and the position of the inserting mechanism is adjustable.

- 1.7 Fast line change: the initial change takes about an hour, and once you become proficient, it can be easily completed within 15-30 minutes.

Machine Operation Process:

Multi-Blade Impeller Production Line Video:

Altron Improved Multi-Blade Impeller Production

-

- Reduce the existing manpower in the production line and reduce labor costs and management costs.

- Reduce the rate of human-caused defects.

- Overall improve the stability of product processing and improve product quality.

- Improve overall work efficiency and gradually realize unmanned production

- Improve existing automatic production lines.

- Add new workstations or equipment.

- Improve production impeller efficiency to 1-2 PCS per minute

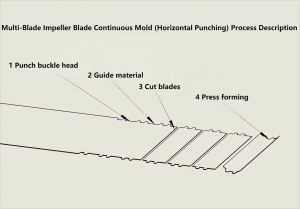

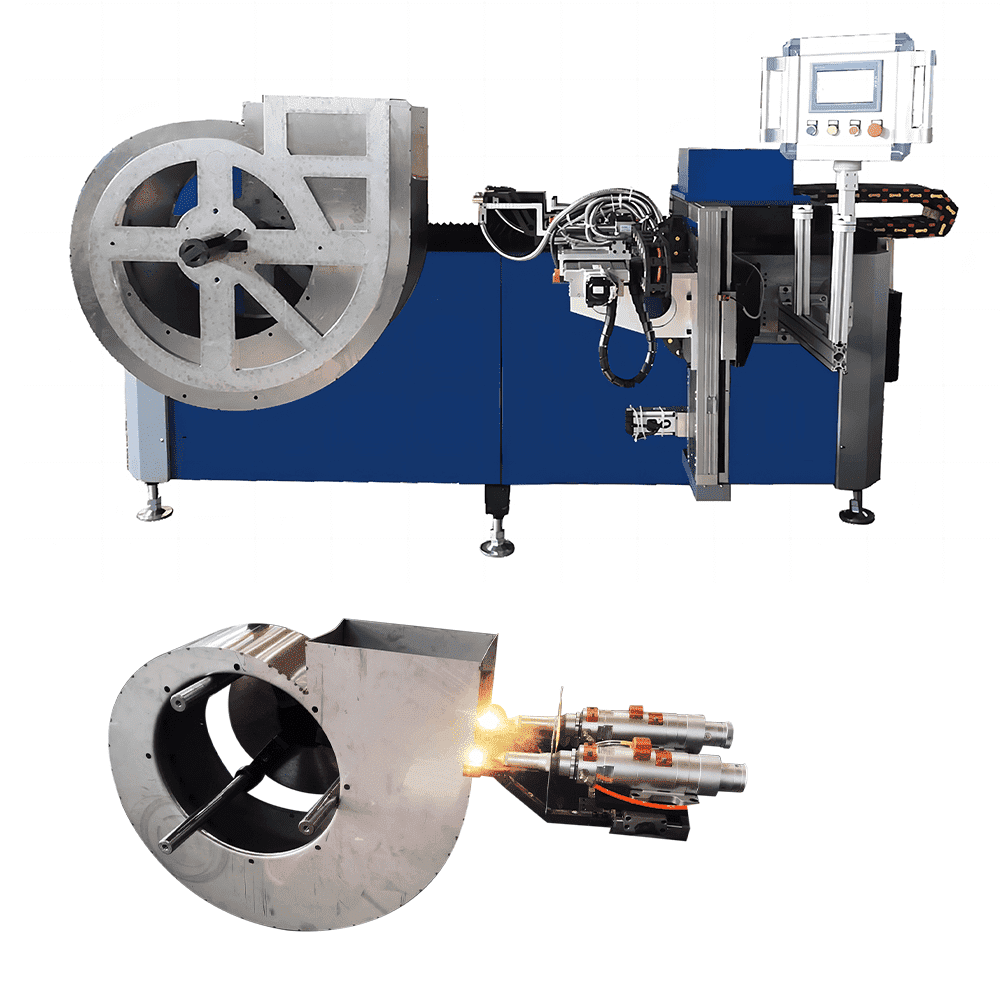

Multi-Blade Impeller‘s Blade Continuous Forming Mold (Horizontal ) Process

Altron offers a variety of coil continuous stamping blade and cutting production lines or coil continuous rolling blade forming and cutting production lines!

Joby engineers recommend that the cross-cutting process is more stable for blade height control! In the later stage of impeller assembly and impeller dynamic balancing, and production are more stable!

Impeller Blade Stamping Process:1 Punch head 2 Guide material 3 Cut blades 4 Press forming

Multi-Blade Impeller Ring And Bottom Plate Stamping Accessories

Impeller base plate and upper ring punching machine processing: When the diameter is larger, the impeller punching machine is used; on the contrary, if the diameter is less than 300mm, the coil material can be used with a continuous punching machine to increase production!

Impeller Automatic Forming Production Machine Assembly Factory

Multi-Blade Impeller Production Line Video:

| Diameter | Impeller height | Blade thickness | Blade reserves (Blade) | Processing efficiency | Power rating |

| 70-130MM | 30-150MM | 0.3-1.0MM | 1000PCS T=0.6MM | 80-120PCS/H | 1.5KW |

| 80-150MM | 30-150MM | 0.3-1.0MM | 1000PCS T=0.6MM | 80-120PCS/H | 1.5KW |

| 100-300MM | 120-250MM | 0.3-1.2MM | 750PCS T=0.8MM | 65-95PCS/H | 2.2KW |

| 300-500MM | 120-250MM | 0.5-1.5MM | 600PCS T=1.0MM | 45-65PCS/H | 3.0KW |

| 500-800MM | 100-350MM | :0.5-2.0MM | 600PCS T=1.0MM | 25-60PCS/H | 4.5KW |

| 120-300MM | 50-200MM | 0.3-1.5MM | 600PCS T=1.0MM | 40-65PCS/H(single layer) 60-100PCS/H(Double layer) |

2.2KW |

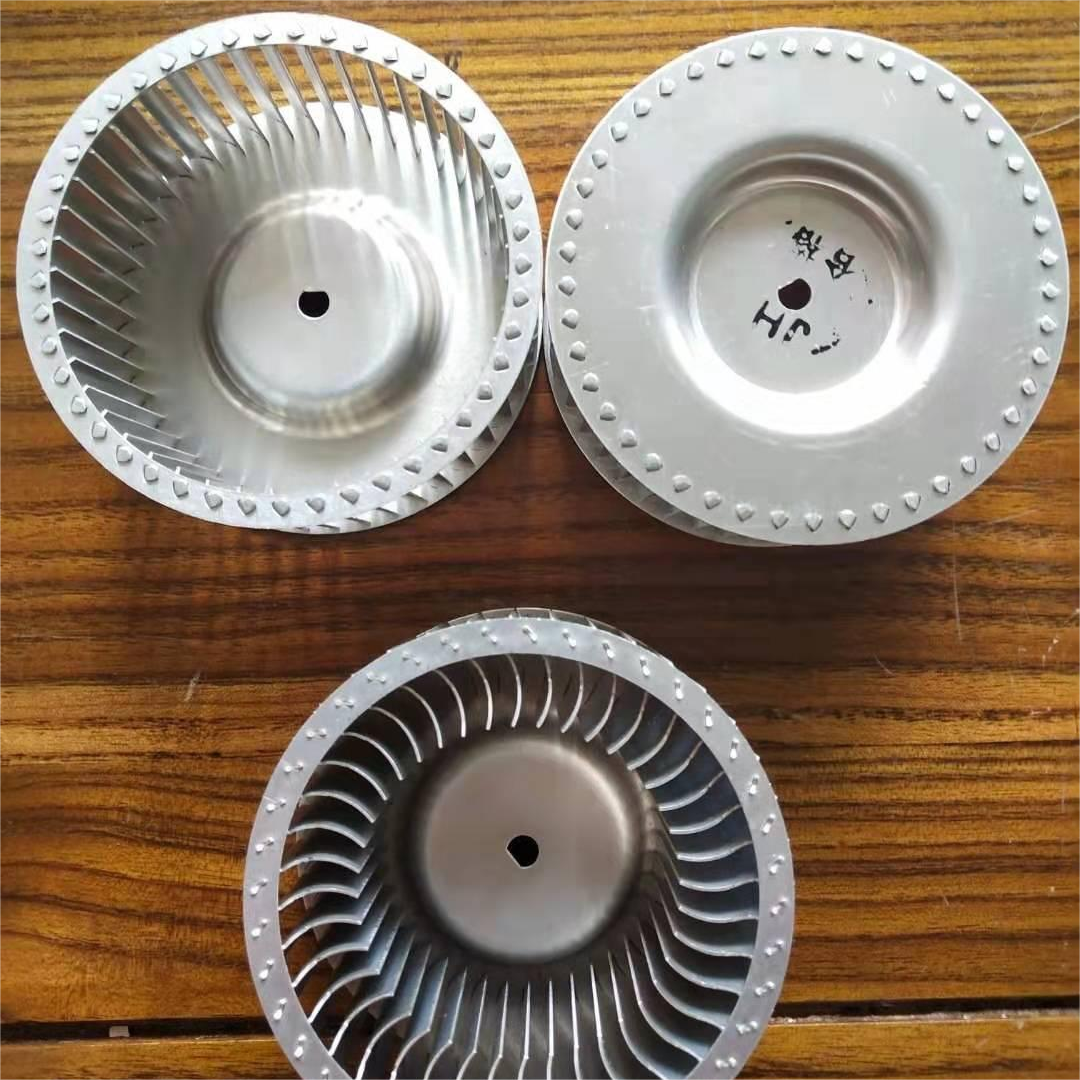

multi-blade impeller sample

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the imperller Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The impeller forming Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.