Double-Gun Centrifugal Fan’s Casing Welding Machine

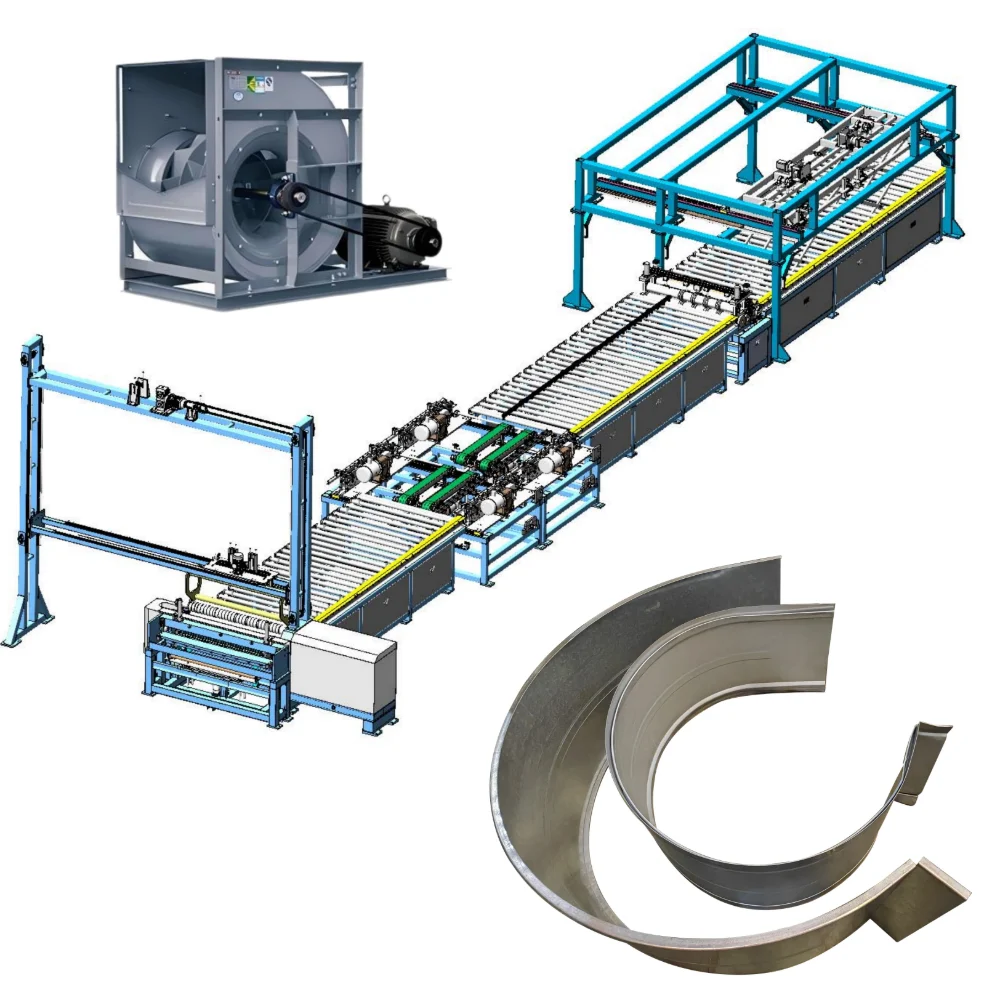

Welding For Centrifugal Fan Casing

|

Machine Name |

Double-Gun Welding Machine |

|

Model |

AC 2WK(Laser, gas shielded welding, argon arc welding) |

|

Application Industry |

Centrifugal fan’s housing, casing |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

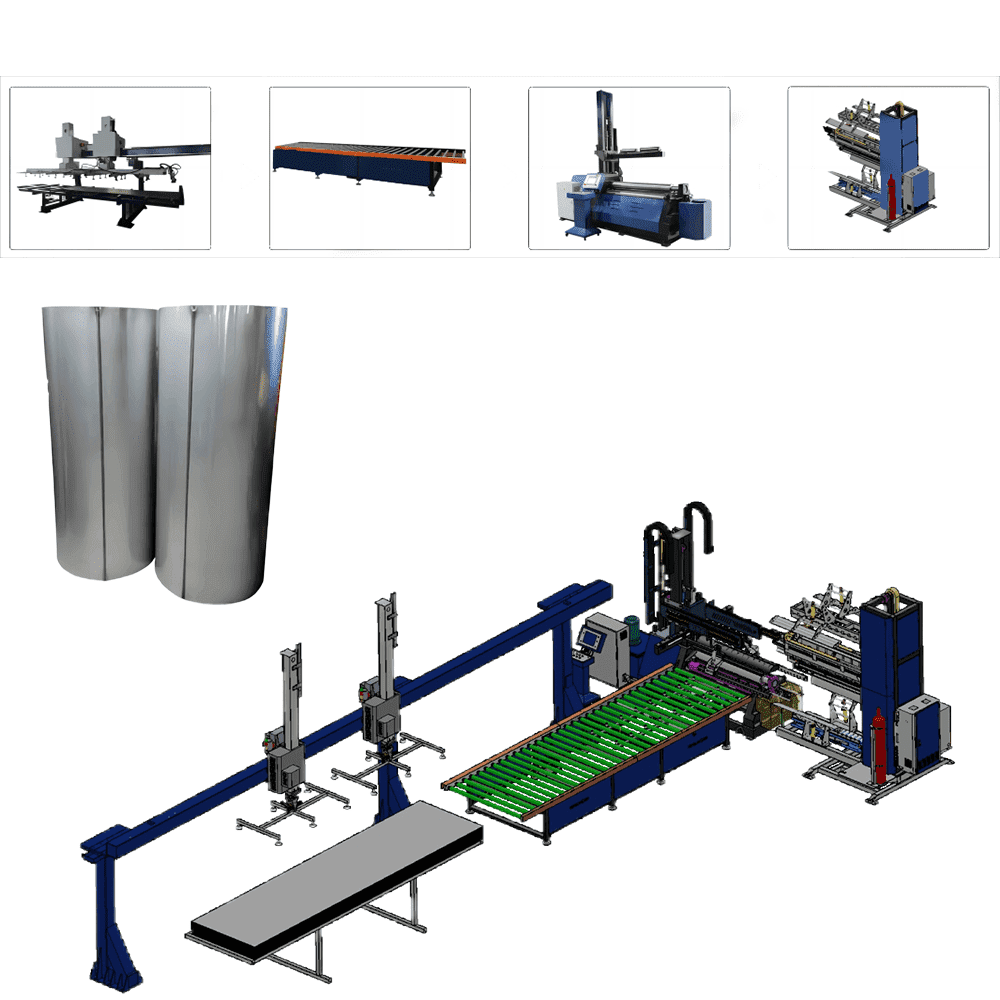

Automatic welding A-Z Project:

1 Centrifugal fan housing vertical welding machine 2 Centrifugal fan casing horizontal welding machine 3 Robot AI welding machine, 4 Gantry welding, 5 Laser welding,

- DETAILS

- PARAMETERS

- CUSTOMER TESTIMONIALS

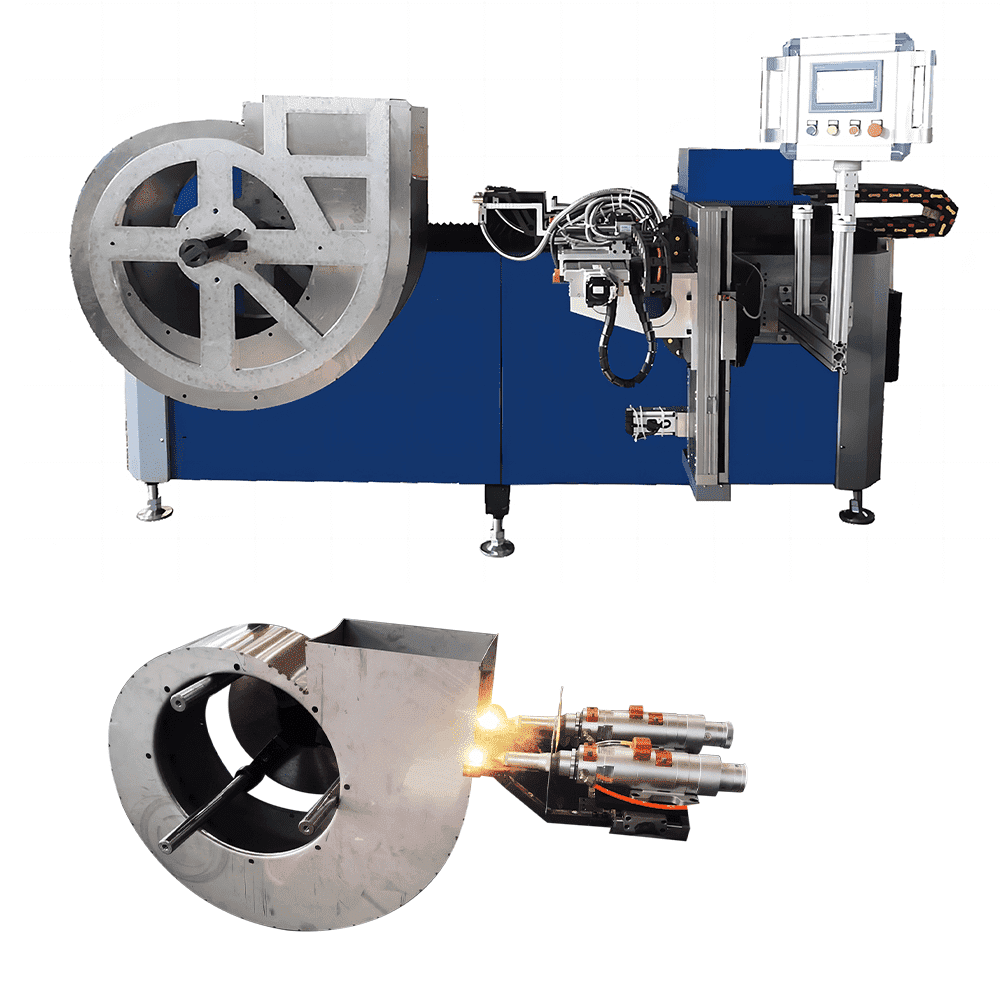

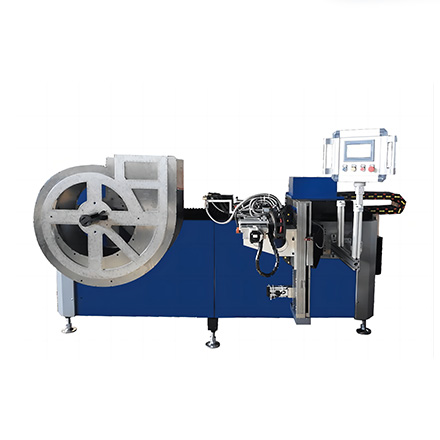

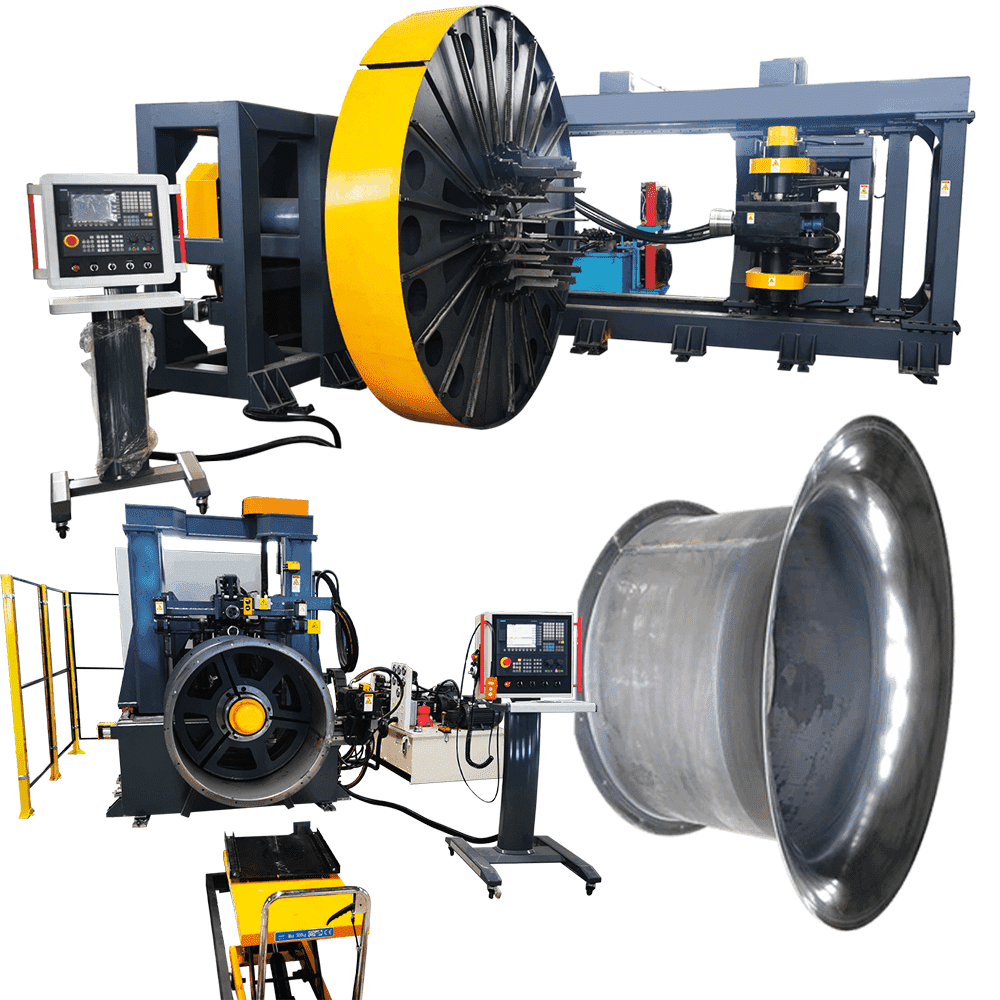

Altron’s dual-gun centrifugal fan casing welding machine realizes a control method without programming. The machine interface inputs the maximum and minimum radius, length and width of the straight edge of the centrifugal fan casing to start the welding process, and is equipped with a profiling function. The mechanical contour ensures stability and reliability, and can correct the weld deviation in real time to achieve the best welding effect.

Double Welding Laser Welding Gun Centrifugal Fan Casing Welding Machine Video

Advantages of Dual-Gun Centrifugal Fan Casing Welding Machine

- Automatic welding without programming, enabling automatic welding of volute workpieces without manual intervention.

- Manual switching function available for manual control adjustments when required.

- System controls crucial parameters like welding speed, with fault alarms and prompts for manual intervention in case of equipment failure.

- Simultaneous welding on both upper and lower sides of the workpiece, eliminating the need to flip the workpiece.

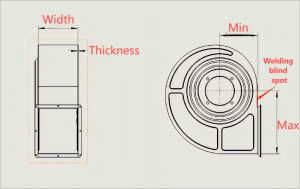

- Fan casing should be wrapped for convenient copying and positioning, with a minimum hemming size specified.

- At least one side of the fan casing must be flat, featuring a round hole in the center for positioning and clamping.

- Suitable for circular flange workpieces and similar components within the welding technical requirements.

- Volute thickness should be a minimum of 1.5mm.

- Workpiece materials: carbon steel, stainless steel.

- Equipment supports a minimum welding diameter of 300mm, maximum welding diameter of 3000mm, and a distance of 64-500mm between upper and lower welds.

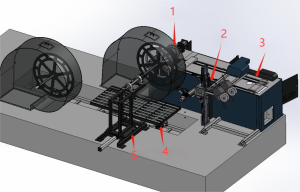

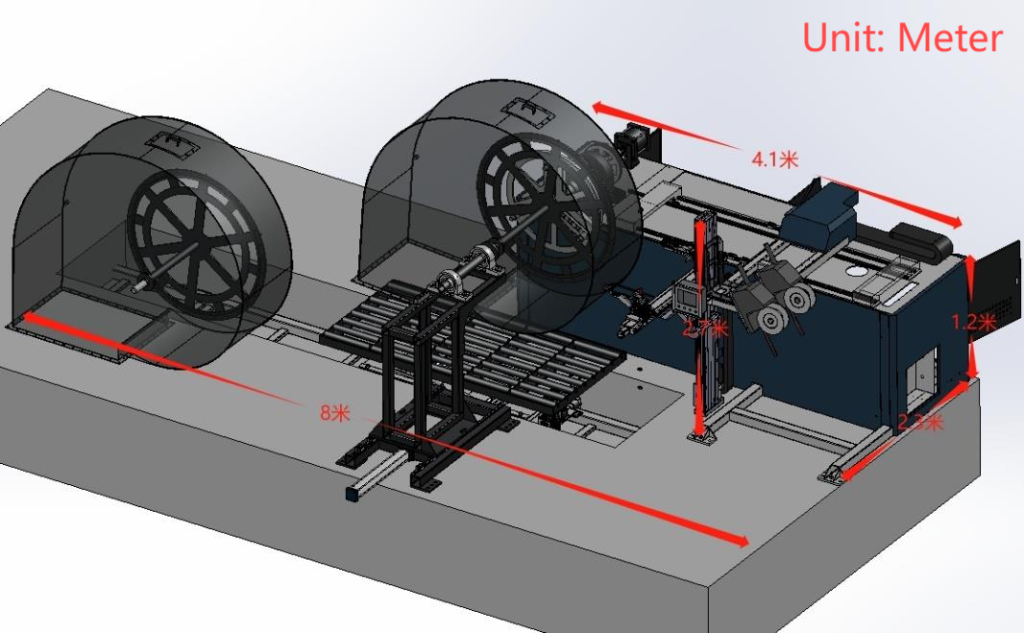

Structure Of Dual-Gun Centrifugal Fan Casing Welding Machine

- Base Platform: Provides installation and positioning of each device component, ensuring stability and preventing excessive shaking during welding.

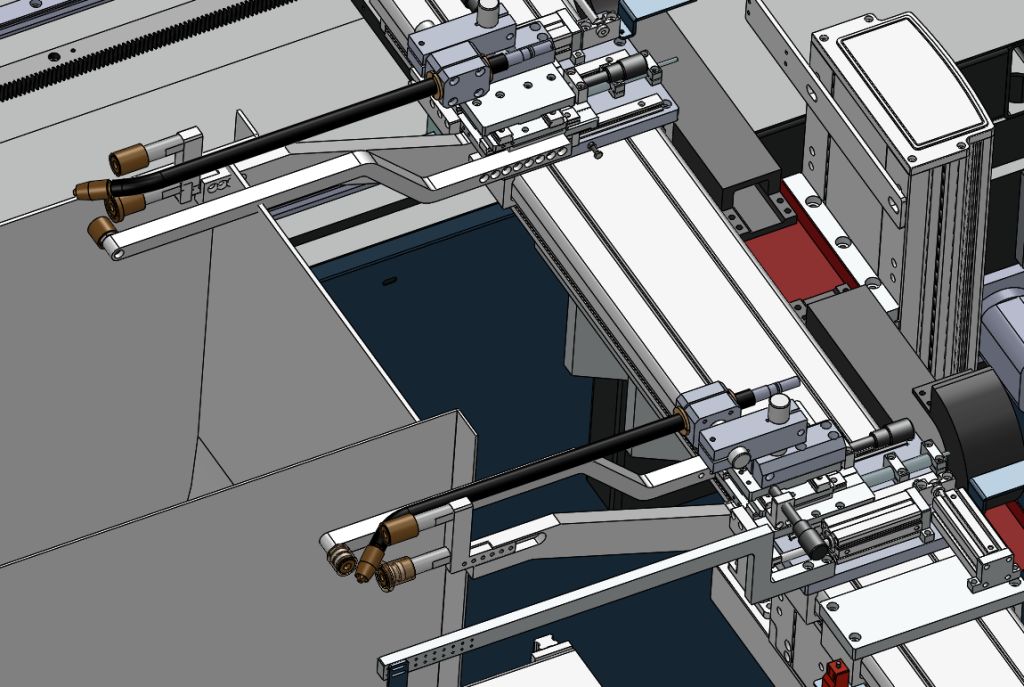

- Mechanical Profiling Double-Gun Manipulator: Profiles the weld bead of the workpiece, accommodating deformations within a 50x50mm vertical plane centered on the welding point. Simultaneously welds upper and lower welds without the need for flipping or secondary positioning, significantly improving efficiency for large workpieces.

- Rotating Bottom Bracket: Offers a flat surface for the workpiece to rest on and allows 360-degree rotation. Equipped with an outrigger top block, facilitating alignment of the workpiece’s bottom round hole.

- Electric Control System: Includes a main control PLC, a user-friendly human-machine control interface, peripheral servo system, various sensors, and intelligent elements for efficient operation.

Dual-Gun Centrifugal Fan Casing Welding Machine consists of a 3-axis welding manipulator, a rotary table, a base, a welding tracking system, a control system, and a MAG welding power lamp. The welding track is set by the system to match the workpiece size, the welding gun automatically guides the workpiece to perform contact elastic profiling tracking, and the welding height is automatically adjusted by the welding voltage.

Customized Double-Gun Centrifugal Fan Casing Welding Machine

Altron‘s Centrifugal Fan Housing Welding solution adopts gas shielded welding technology and mechanical profiling welding (mechanical profiling requires that both sides of the centrifugal fan housing are flat and without reinforcement ribs). The equipment has a welding blind spot, and the mechanical profiling mechanism cannot enter, which will cause the last small section to be unable to be automatically welded.

Welding Steps For Centrifugal Fan Casing

Pre-operation debugging:

1. Input the required workpiece parameters, such as material thickness, minimum and maximum diameters, width and other information.

2. Adjust the parameters of the welding machine and wire feeding equipment.

3. Fix the workpiece to the rotating fixture on the spindle part! Two fixing methods:

① Pneumatic clamp (for centrifugal fan housing with thicker wall thickness),

② Disc fixing (for housing with thinner wall thickness or larger and heavier centrifugal fan).

Operation welding process:

1. After the centrifugal fan housing is fixed, press the start button, and the welding part automatically moves to the contour welding position according to the input workpiece parameters.

2. The equipment starts automatic welding according to the input data.

3. After welding is completed, remove the welded centrifugal fan housing and weld the next housing.

Customized Double Gun Centrifugal Fan Housing Welding Video

Industrial Centrifugal Fan Welding Effect Diagram

Configuration

Mainly used for centrifugal fan volute welding

Large Diameter Double Welding Gun Industrial Centrifugal Fan Casing Welding Video

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

Upon receiving the machine, I promptly watched the training video provided and attempted to initiate its operation. I must commend the after-sales service for their exceptional patience and helpfulness throughout the process. The equipment’s operation proved to be remarkably simple, allowing me to quickly understand its functioning and get it up and running smoothly.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The delivery was exceptionally swift, and I was pleasantly surprised by the speed of the process. Furthermore, I must express my utmost appreciation for the remarkable after-sales service provided.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The machine itself operates at an impressively accelerated pace compared to others in the market, exceeding my expectations.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

After three months of usage, I am delighted to report that the machine has consistently delivered excellent results. I am thoroughly satisfied with its performance and efficiency. In fact, I am so impressed that I have already made plans to purchase another one in the near future.