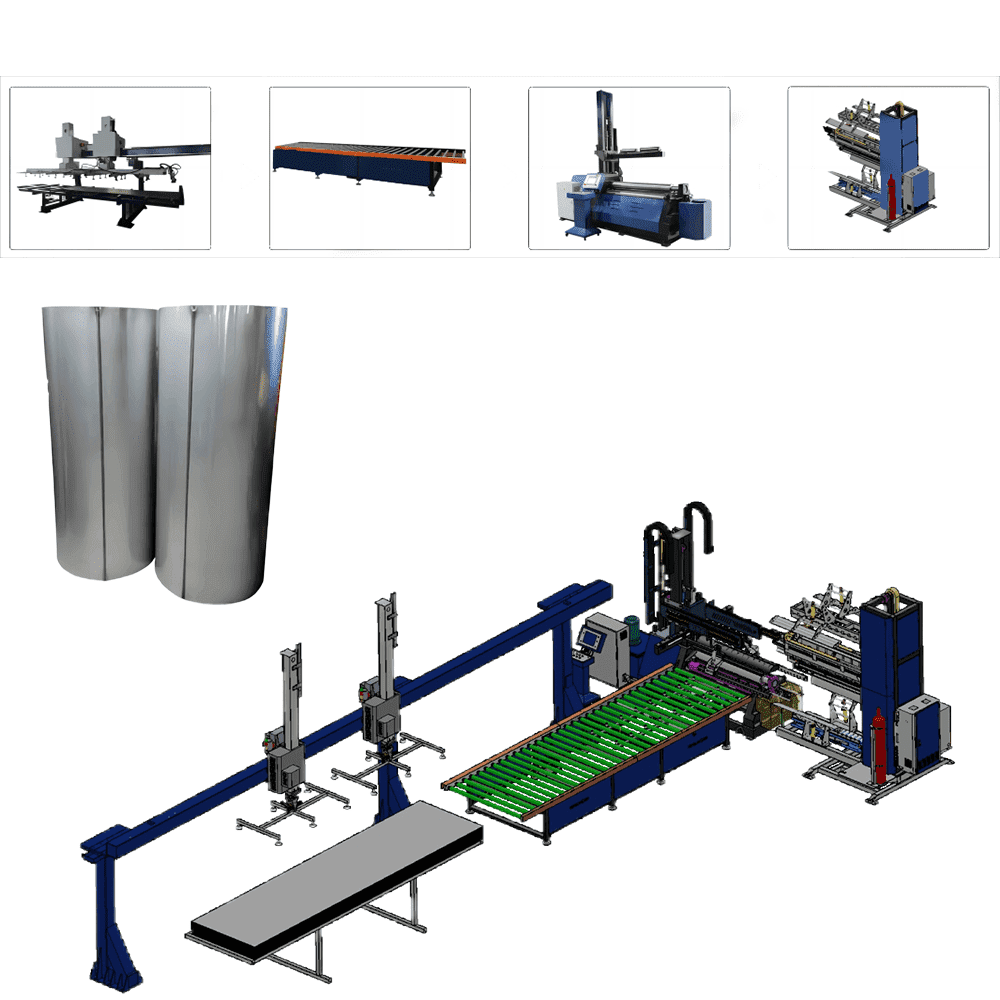

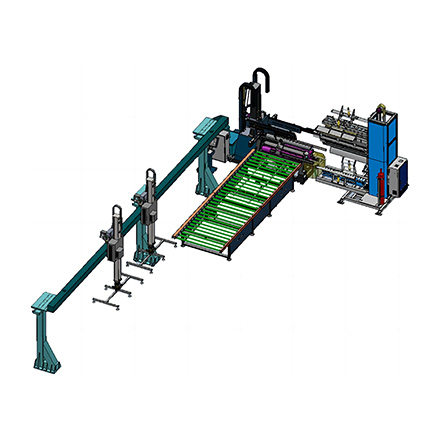

Rolling & Welding Production Line

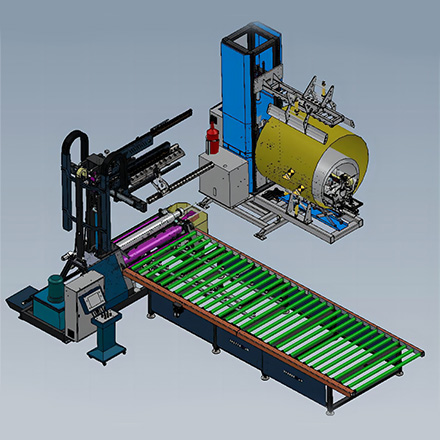

Rolling & welding production line for cylinder duct

|

Machine Name |

AUTO-Rolling & Welding Production Lines |

|

Model |

AC-JH 1500 Custom |

|

Application Industry |

Ventilation Ducts, Axial Fan, Water Storage Tanks, Cylindrical Barrels, Etc. |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Industrial Fans A-Z Project:

1 Rolling 2 Seam Welding 3 Production Line, 4 Flanging , 5 Spinning,

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

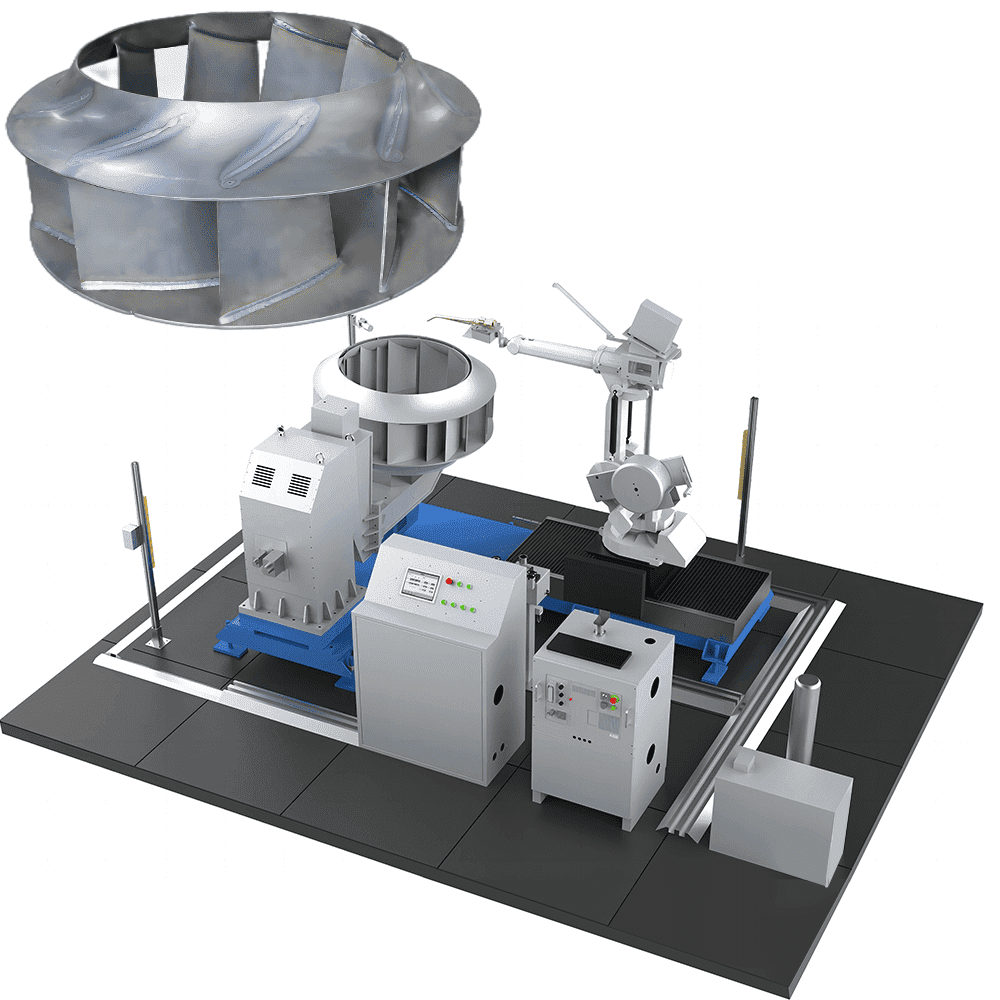

Altron’s rolling and welding production line mainly produces cylindrical metal barrels, which are widely used in Industrial Fan Ducts, Ventilation Ducts, Axial Fan Ducts, Fire Protection Ducts, Water Storage Tanks, Cylindrical Barrels, and other industries; it can be customized to produce different materials: stainless steel, aluminum, iron, copper, carbon steel and other special materials cylindrical rolling barrel welding automatic production line.

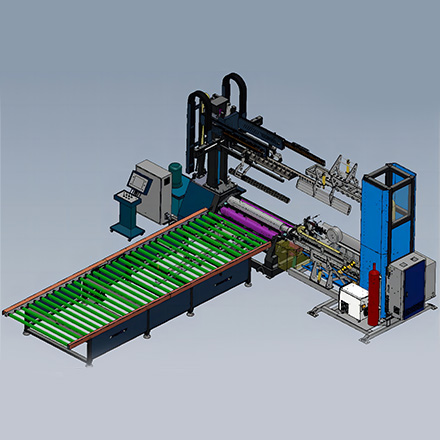

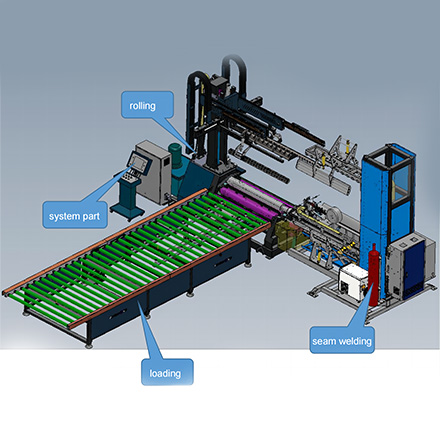

AC-JH 1500 Rolling & welding production line main functions:

Process of Rolling & Welding Production Line

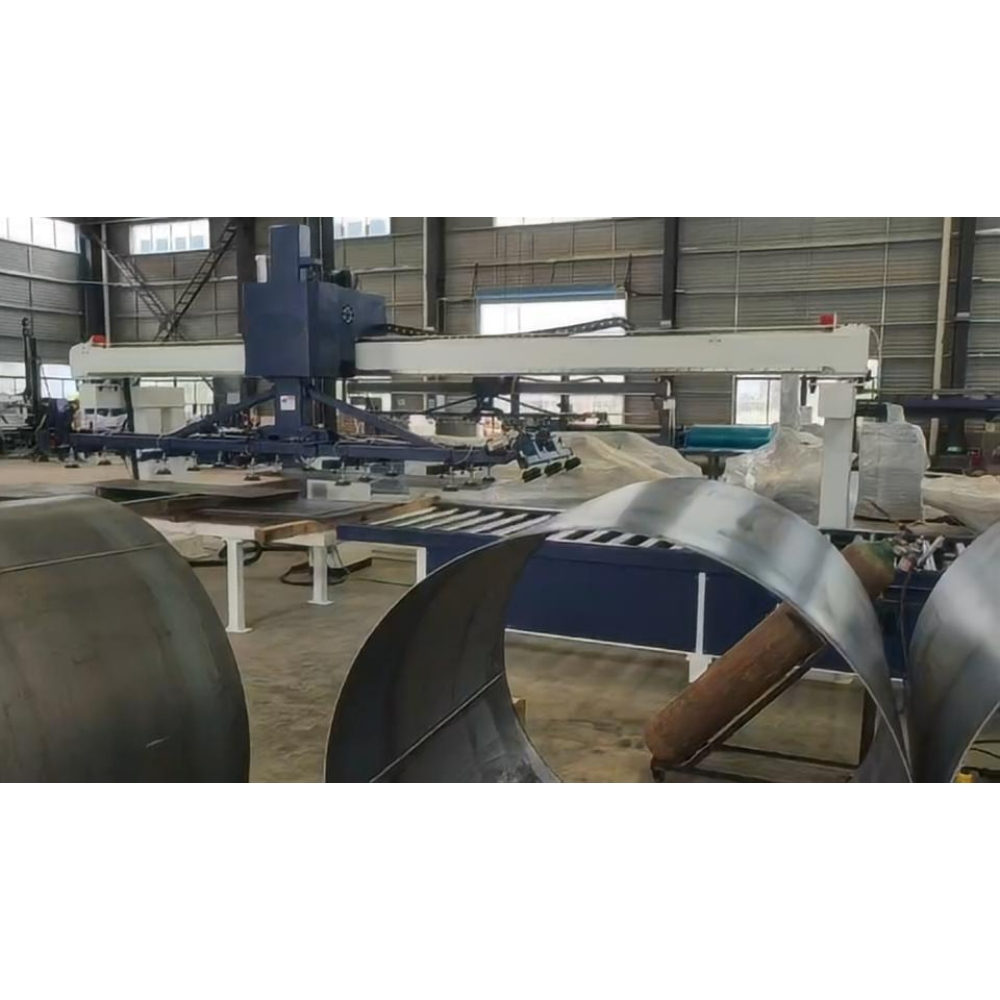

Altron automatic heavy-duty roll welding production line, the corresponding specifications completed by laser cutting are placed on a fixed material tray; the production line controls the translation loading robot to automatically pick up the material and put it on the conveying platform; it automatically positions and enters the high-precision roll forming machine for roll forming;

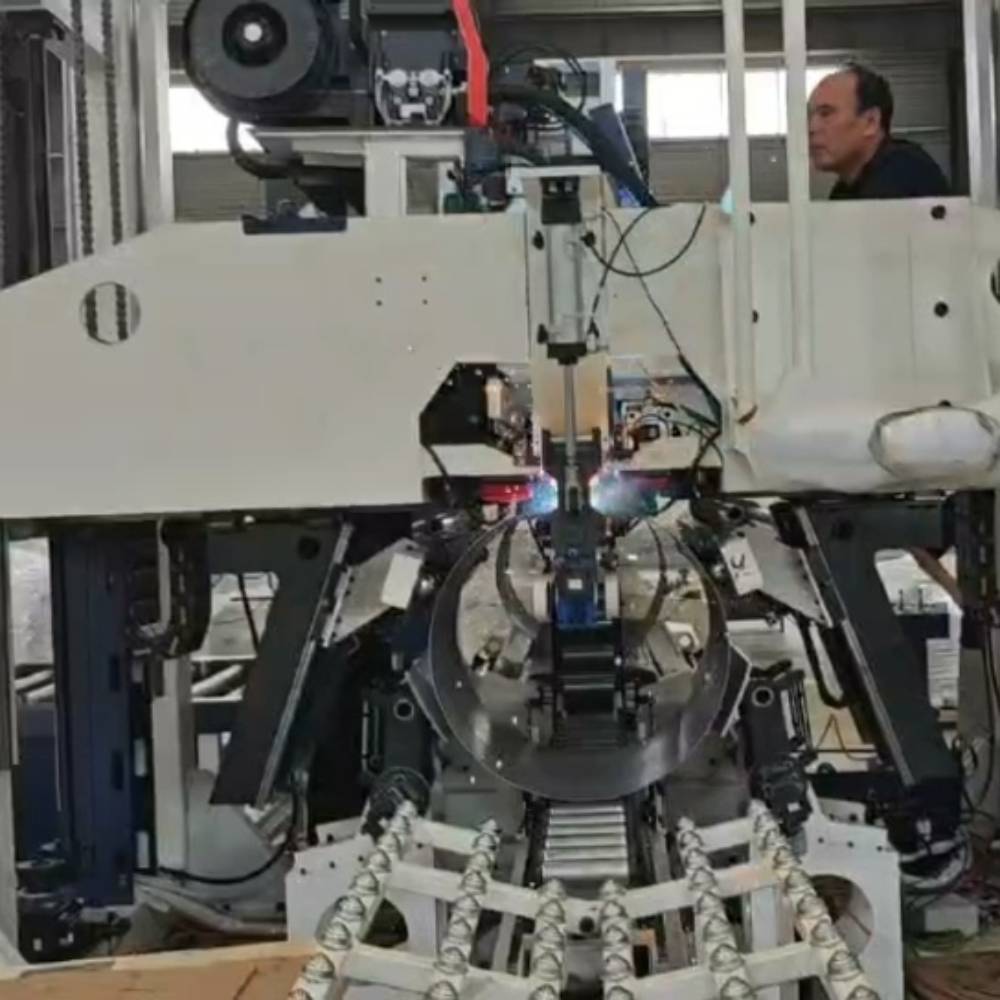

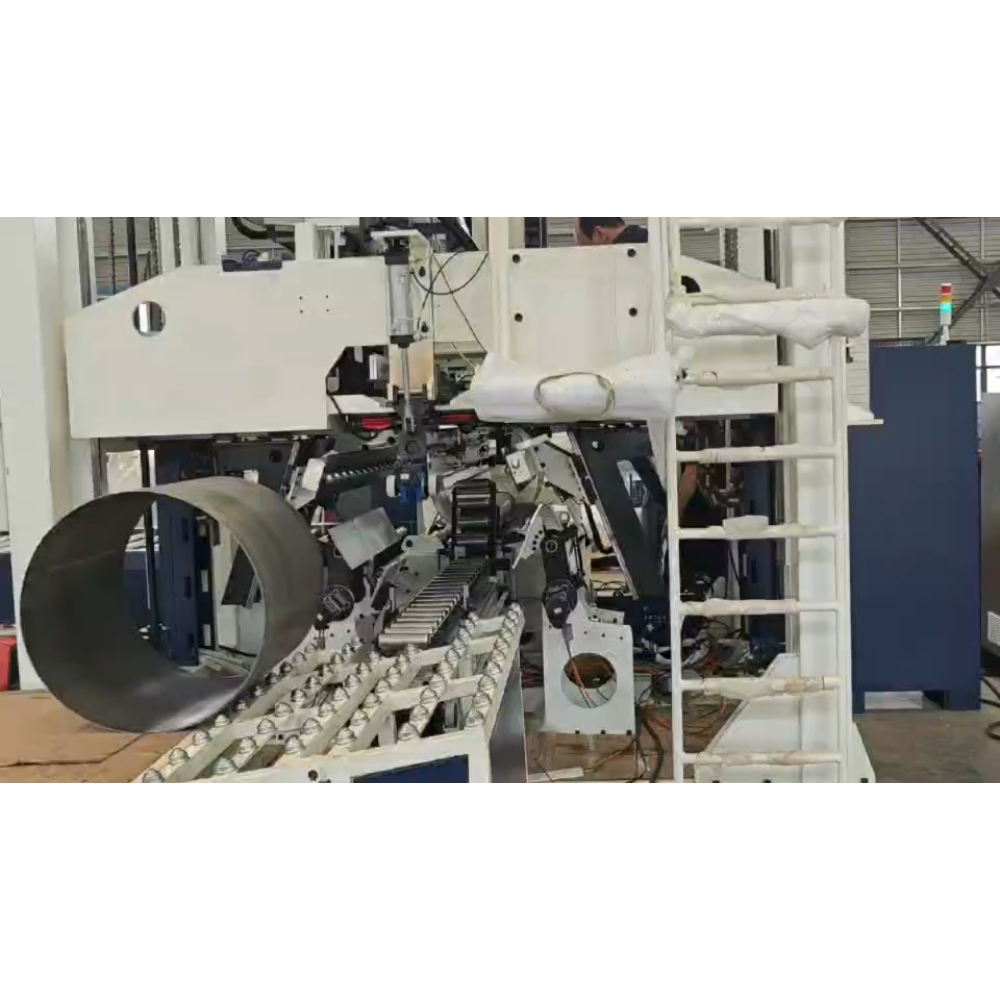

Automatically find the position of the weld, automatically feed the straight seam welding tooling, and automatically position it! There are multiple auxiliary fulcrums on the side of the wind tube for positioning. This mechanism ensures the stability of the entire roll roll welding production process! The production line is equipped with video monitoring, and real-time feedback tracking of welding quality!

Rolling & Welding Production Line Video

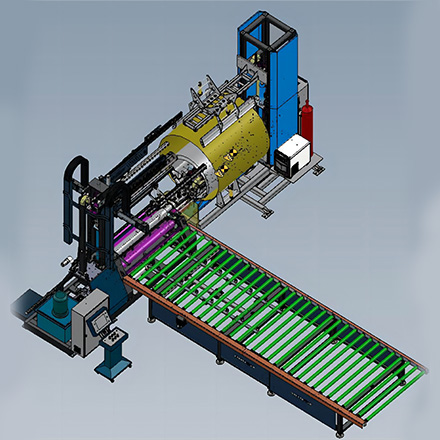

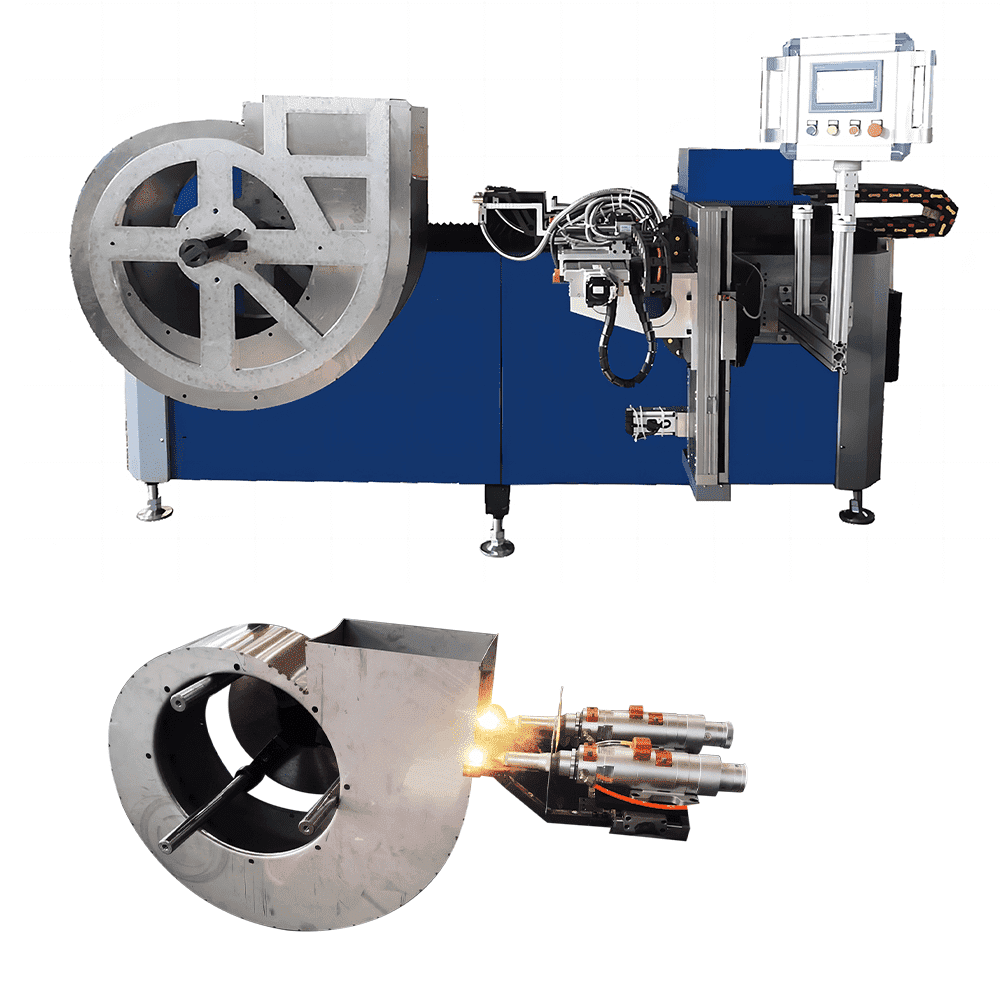

Processing range: diameter 600-1350mm, height 530-1000mm, wall thickness 2-5mm carbon steel!

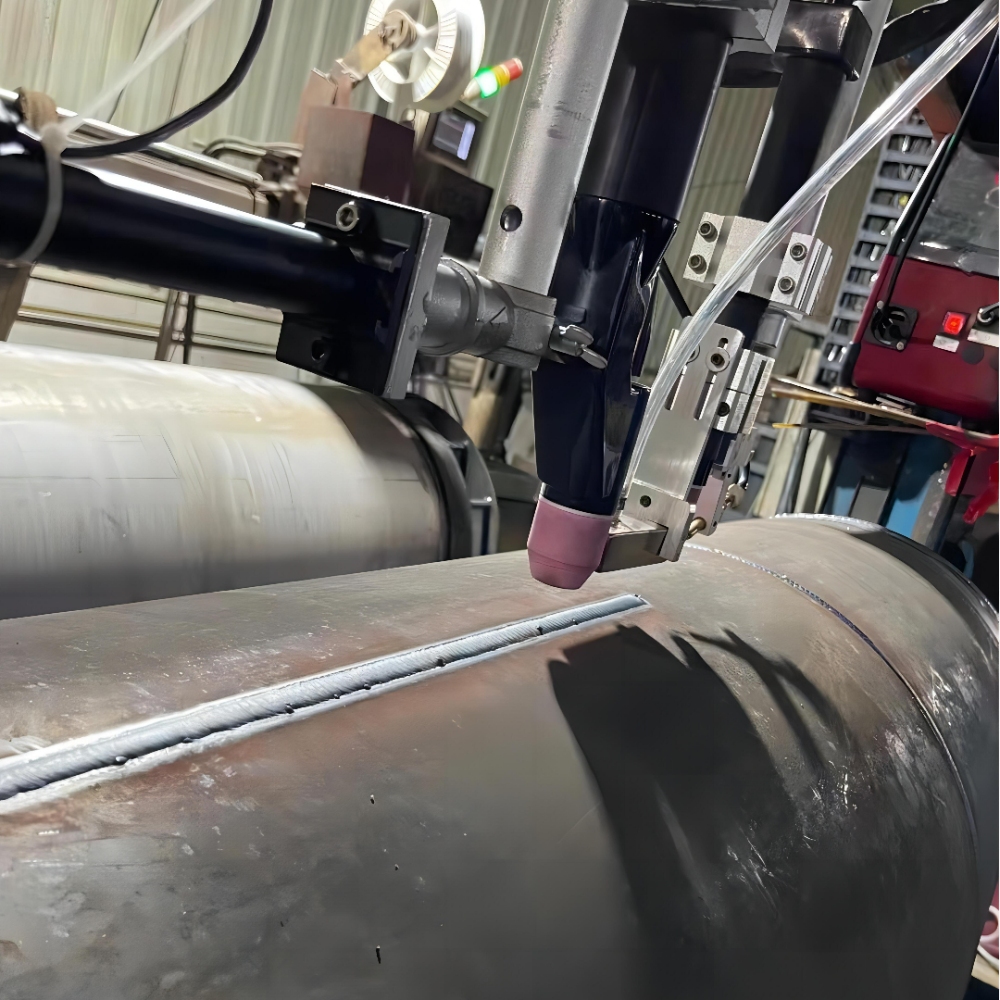

Welding adopts gas shielded welding, and the protective gas adopts 80%Ar+20%CO2; welding is performed from the outside; the end face misalignment error on both sides: within plus or minus 2mm! Welding is required to be firm, the weld is uniform, and there is no welding through!

Production line rhythm and efficiency: feeding speed 100mm/s, rolling speed 50mm/s, welding speed 12mm/s, according to the production efficiency of carbon steel materials: diameter 908, height 900, thickness 3.5mm, the overall efficiency of the production line is to complete the welding of one wind tube every 3 minutes!

Introduction To Rolling & Welding Automated Production Lines

Automatic feeding:

ensure that the plate reaches the positioning platform of the rolling machine smoothly during the transmission process of the translational robot arm.

Rolling process:

The positioning platform ensures that the plate is fed into the rolling machine in a vertical direction, and the head and tail of the roll can be aligned.

Welding capacity:

The welding water in the seam welding process completely penetrates the plate, and the plate of the roll is firmly fixed.

Automation and efficiency:

The production line is fully automated and can run continuously. It minimizes labor, shortens production time and cycle; improves efficiency and quality, reduces the site usage area for manufacturing rolls, and saves turnover of different processes.

Customization options:

The production line can be customized according to specific requirements! Pipe diameter, length and material.

Quality control and monitoring:

The production line is equipped with laser positioning function and high-precision mechanical positioning; multiple monitoring cameras, and IoT system or remote monitoring system can be selected to allow factory management to always grasp the status of the production line.

Rolling & welding production line-Rolling

-

Full load minimum roll value: Φ300 mm

-

Coil maximum width: 1500 mm

-

Full hydraulic drive: The machine utilizes a full hydraulic drive system, offering high efficiency and energy savings. Compared to traditional machines, our hydraulic drive system operates at 60% higher efficiency. This ensures smooth and efficient operation during the rolling process, providing superior performance.

-

Safe and Reliable Operation: The machine is designed with utmost safety considerations, ensuring a secure working environment for operators. The trigger mechanism is reliable, minimizing the risk of accidents or equipment malfunctions. Operators can have peace of mind knowing that safety is a top priority in the design and functionality of our machine.

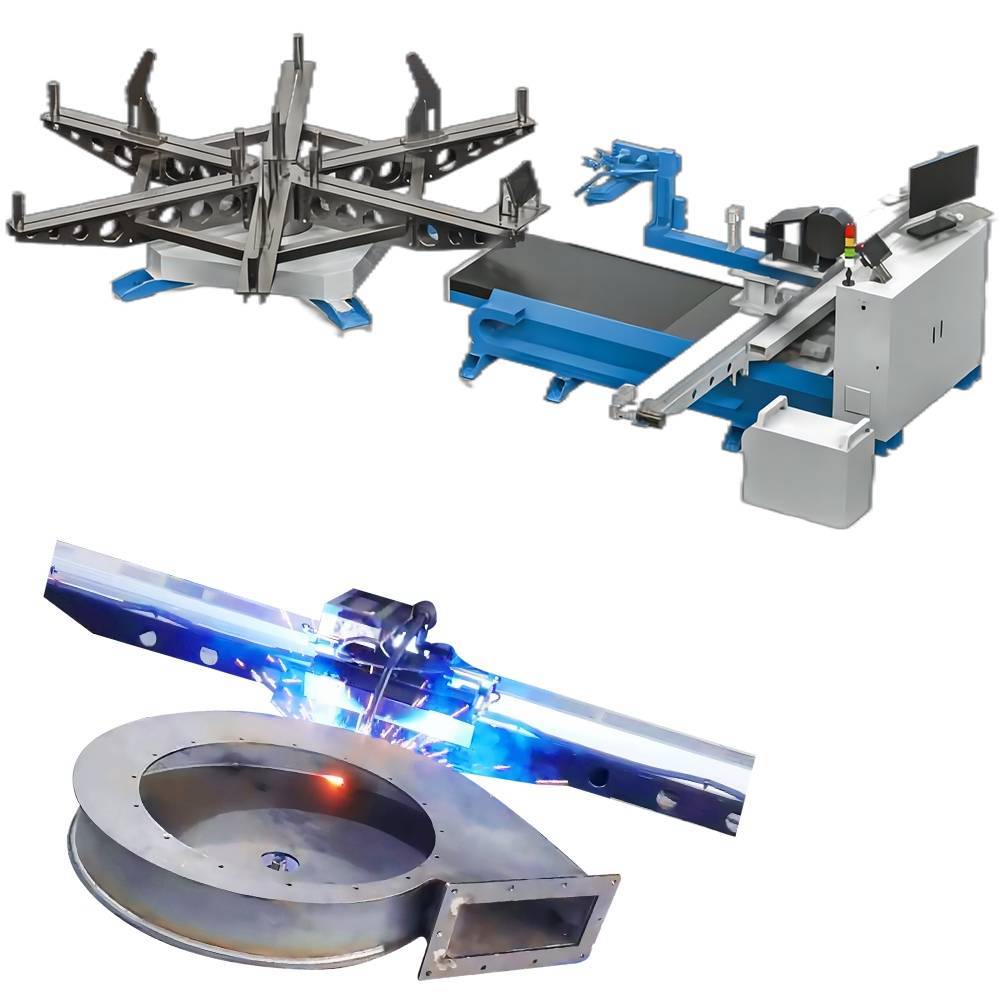

Rolling & welding production line-Seam Welding

- Processing Stroke: 1500 mm

- Welding Materials: Carbon steel, galvanized sheet, stainless steel

Altron’s welding equipment is designed for cylindrical seam welding and is very suitable for welding cylinders, thin-walled rolls, especially axial fan wind tubes and ducts. It provides accurate and efficient welding capabilities for a variety of materials, including carbon steel, galvanized sheet and stainless steel. The equipment has an automatic lifting function, which can achieve multi-standard welding situations and meet diverse welding requirements.

Rolling & welding production line Applications:

Our roll welding lines are used in a wide range of industries, including:

Production of stainless steel and carbon steel ducts: Used to manufacture high-quality ducts for ventilation systems. The machine ensures precise rolling and welding of stainless steel and carbon steel materials, providing durable and efficient ducts.

Solar water heaters: Our machines are suitable for manufacturing cylindrical components used in solar water heaters. It provides precise material rolling and welding, ensuring the integrity and efficiency of solar water heating systems.

Kitchen and bathroom appliances: The machine can be used to manufacture cylindrical components for kitchen and bathroom appliances, such as exhaust fans and ventilation systems. It ensures precise rolling and welding, which helps improve the overall performance and reliability of these appliances.

Fan fire fighting equipment: Our machines are ideal for producing cylindrical components used in fan fire fighting equipment. It provides precise rolling and welding capabilities, ensuring the structural integrity and safety of the equipment.

Finished cylindrical roll effect of the rolling & welding production line

Different welding processes and welding machines can be selected for different metal materials such as aluminum, iron, carbon steel, galvanized sheet, stainless steel, etc. Commonly used ones are argon arc welding, gas shielded welding, and laser welding!

Configuration

Application areas of Rolling & welding production line

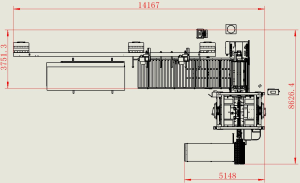

| Workpiece Information | round rolling dia. | Φ400~1500mm |

| round rolling length | 400~1500mm | |

| thickness(SUS.) | 1-4mm | |

| Machine Size (L×W×H) | 13016×8084×4300mm | |

| Material | SUS., carbon steel | |

| Capacity | about 3Min/pcs for Φ600×600mm | |

| Feeding Precision | ±0.5mm | |

| Machine Weight | about 10 Tons | |

| Total Power | 35KW | |

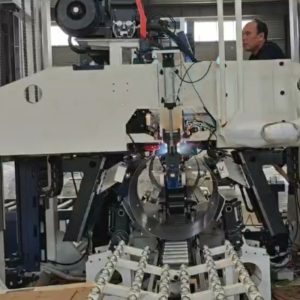

Rolling & Welding production line video

This is the early debugging process of the first generation of rolling welding production line!

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The Rolling & Welding Auto Production Line has been a game-changer for our exhaust fan pipe manufacturing business. The precision and consistency it offers have greatly improved the overall quality of our products.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The automated processes have not only increased our production capacity but also reduced labor costs. The customizable features allow us to produce a wide range of pipe sizes, catering to different customer needs. We are delighted with the efficiency and performance of this production line

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

Since adopting the Rolling & Welding Auto Production Line, our production efficiency has soared. The automation has streamlined our workflow and reduced the need for manual labor, resulting in faster production cycles and increased output.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The quality of the rounded and welded pipes is exceptional, meeting our stringent standards.