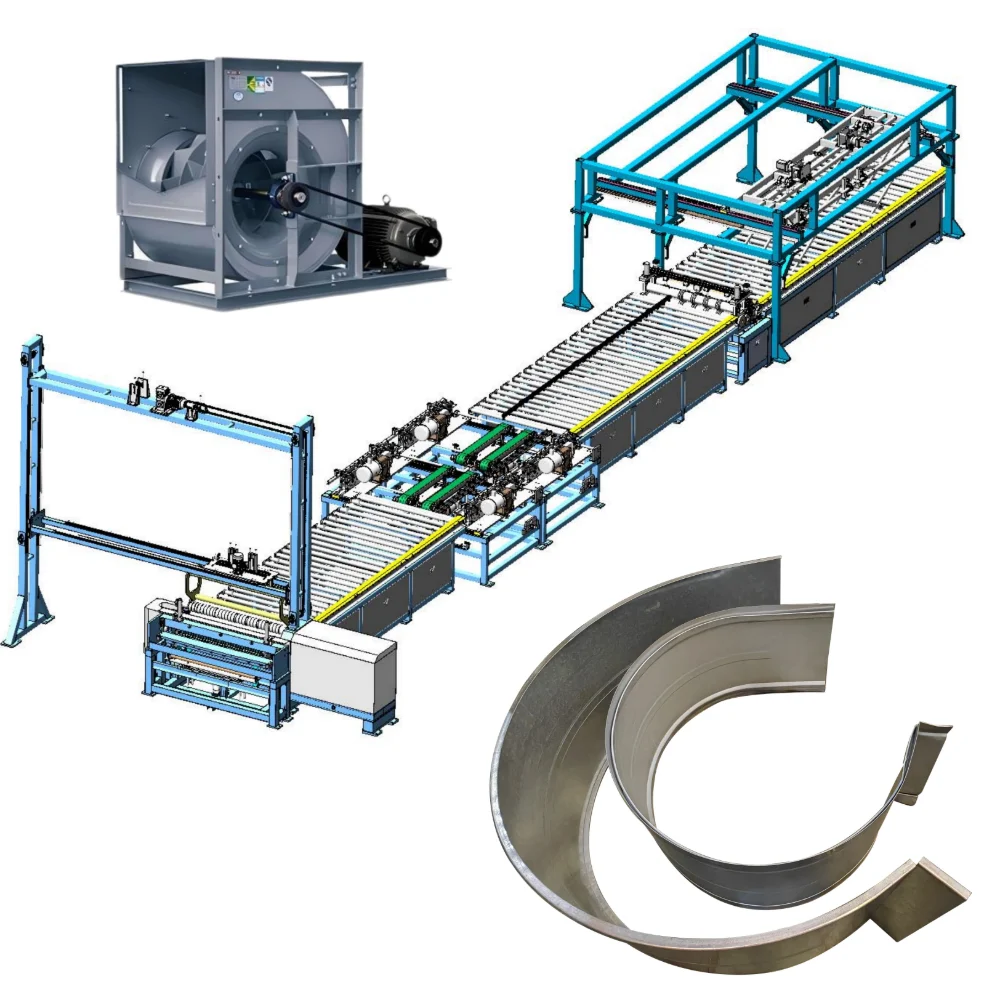

Centrifugal fan housing Forming machine

Centrifugal fan casing or housing forming production line

|

Machine Name |

Centrifugal fan housing formming machine |

|

Model |

AC-HF Customized |

|

Application Industry |

Centrifugal fan casing forming within 1.5mm thickness |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day |

|

Project Progress |

90-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Industrial Fans A-Z Project:

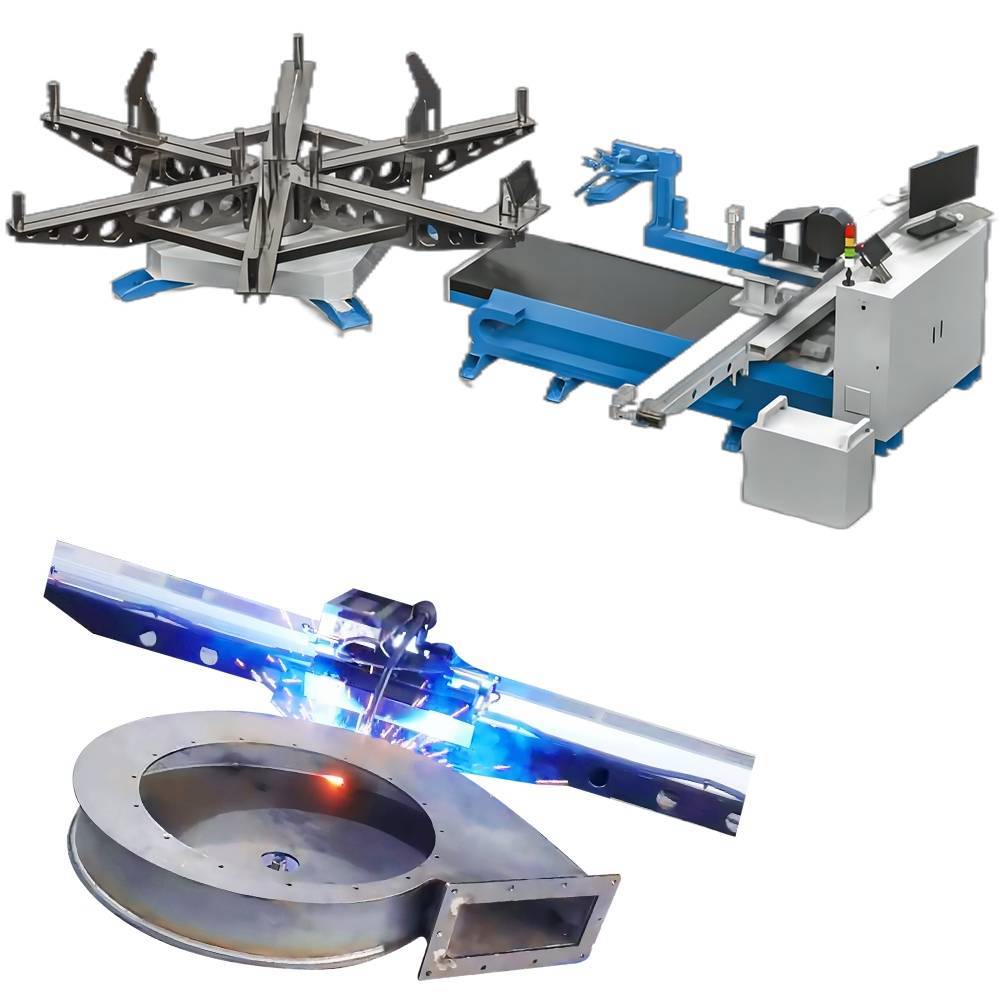

1 welding machine for fan housin 2 Vertical centrifugal fan double gun welding 3 Fully automatic centrifugal fan production line

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

ALTRON centrifugal fan case forming machines are advanced solutions that simplify the forming process of a wide variety of materials.

Applications: Centrifugal fans housing formming machine

- CNC four-roller rounding machine,

- pneumatic bending machine,

- side panel pre-buckle machine,

- CNC forming machine,

Centrifugal fan casing forming video:

Main components and functions of centrifugal fan housing

Discover the pinnacle of precision in fan housing production with the Centrifugal Fan Housing Hemming Machine. From CNC four-stick rounding to pneumatic bending, side plate pre-fastening, and CNC hemming, each stage guarantees unparalleled accuracy, optimal aerodynamics, and seamless assembly for superior performance.

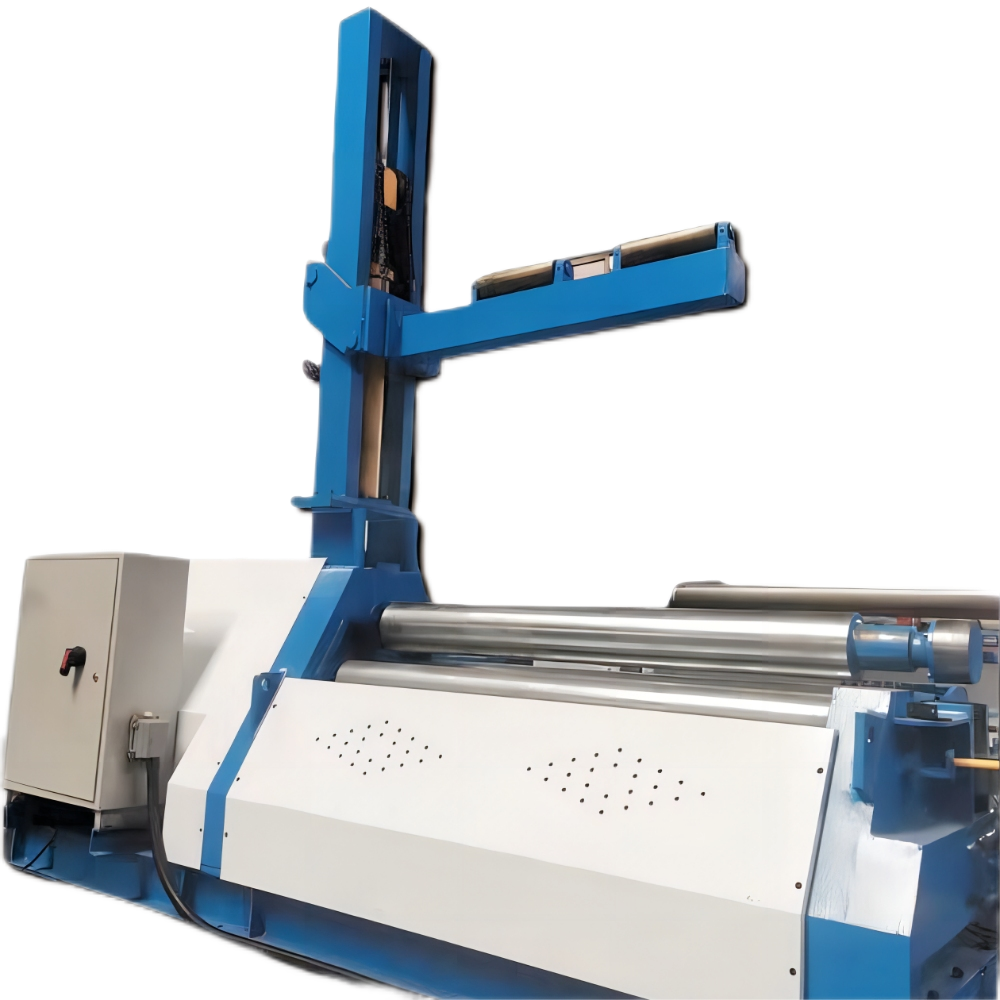

1. CNC Four-Stick Rounding Machine

Precision in Forming

The CNC four-stick rounding machine takes the lead in shaping the initial structure of the fan housing. Its computer numerical control (CNC) system orchestrates the movement of four sticks, meticulously rounding the edges with unparalleled accuracy.

This stage lays the foundation for the subsequent processes, ensuring a flawlessly shaped housing that optimizes airflow.

2. Pneumatic Bending Machine

Controlled buckling

As the rounded housing emerges, the pneumatic bending machine steps in to introduce controlled bends. Pneumatic power propels the bending mechanism, precisely curving the housing to meet the specifications.

This step is critical in achieving the desired aerodynamic profile, ensuring optimal fan performance while maintaining structural integrity.

3. Side Panels Pre-Fastening Machine

Aligning Perfection

Before the housing takes its final form, side panels must be seamlessly integrated. The side panels pre-fastening machine handles this task with finesse. Its automated system aligns and secures the panels, creating a cohesive structure.

This pre-fastening stage streamlines the assembly process, enhancing overall efficiency.

4. CNC Hemming Machine

The Culmination of Precision

The apex of the fan housing production process is reached with the CNC Centrifugal fan housing formming. This sophisticated equipment meticulously folds and locks the edges of the housing, imparting strength and durability.

The CNC precision guarantees uniformity, eliminating any irregularities that might compromise the performance or aesthetic appeal of the final product.

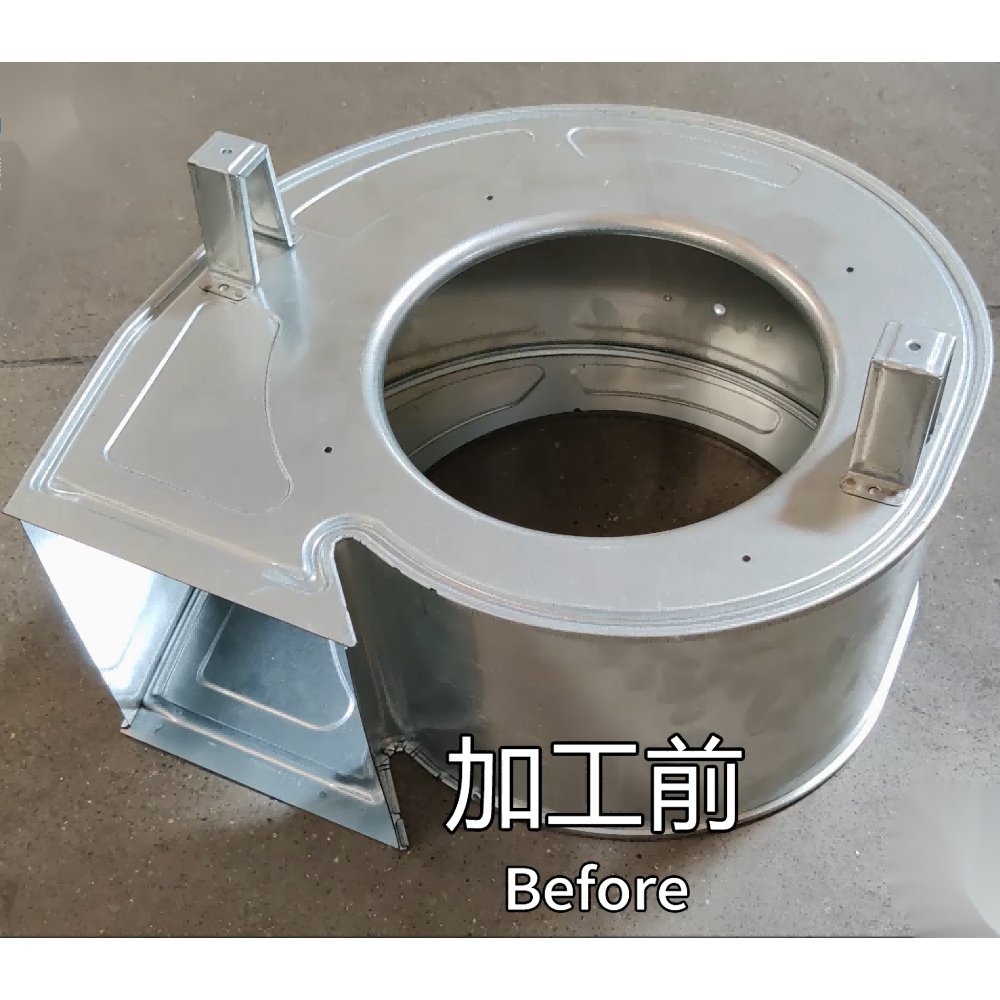

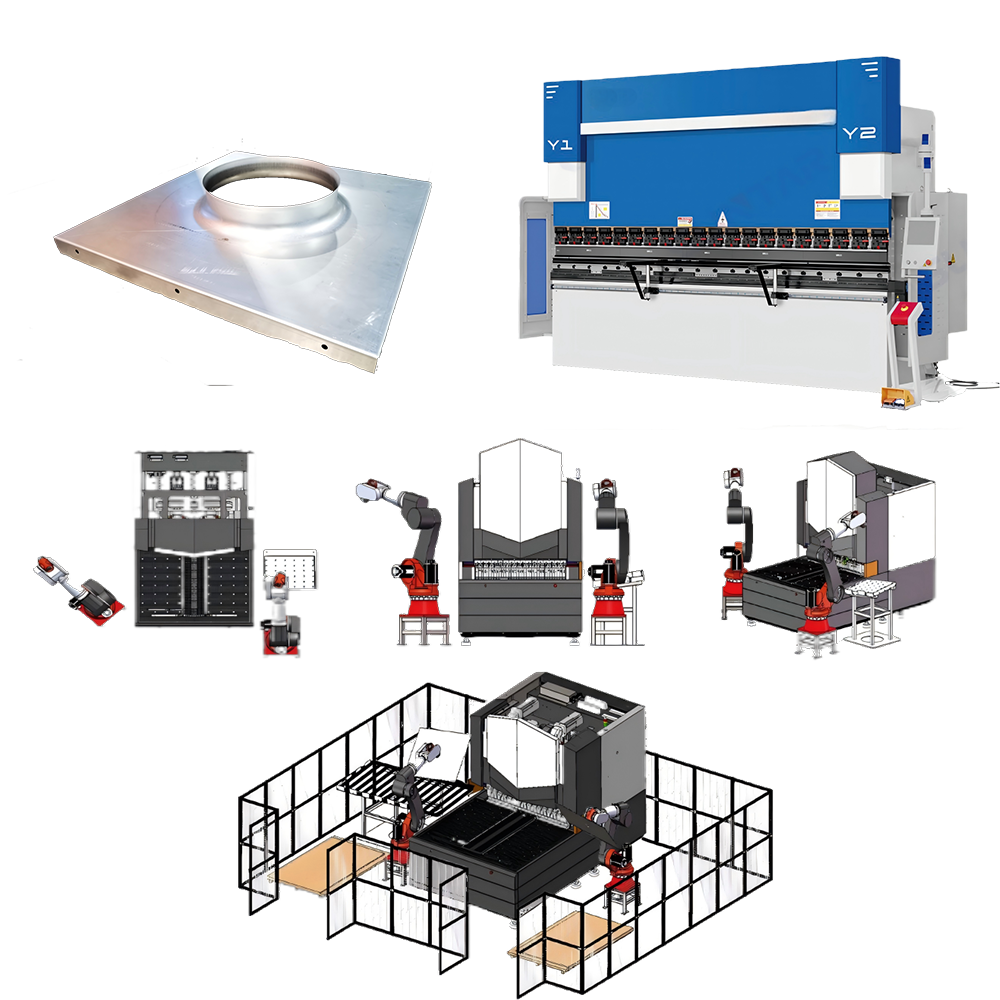

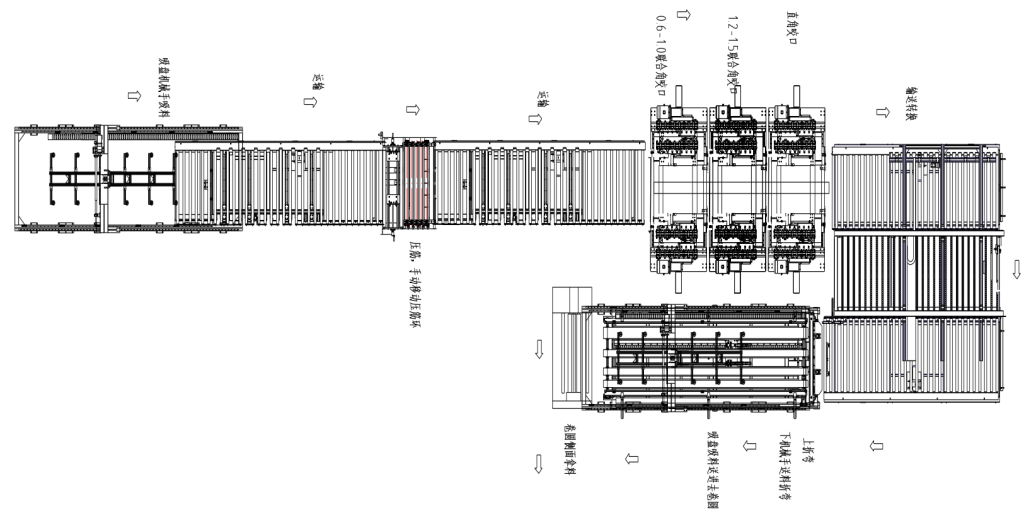

Custom Centrifugal Fan Casing Forming Production Line

Altron designed and customized a fully automatic production line for centrifugal fan housing for Detong Industrial Fan Manufacturer.

Forming processes include: feeding, roll pressing, roll hemming, flanging, rolling, automatic unloading, etc.!

Suitable for galvanized sheet, cold-rolled steel sheet, stainless steel sheet;

Production process: automatic feeding from sheet; fixed-length rib pressing, can roll reinforcement ribs of different widths, lengths, and quantities; automatic fixed-length notch stamping of molds, right-angle forming on both sides or joint corner hemming forming; automatic sheet transportation and centering, automatic feeding to folding and rolling mechanism!

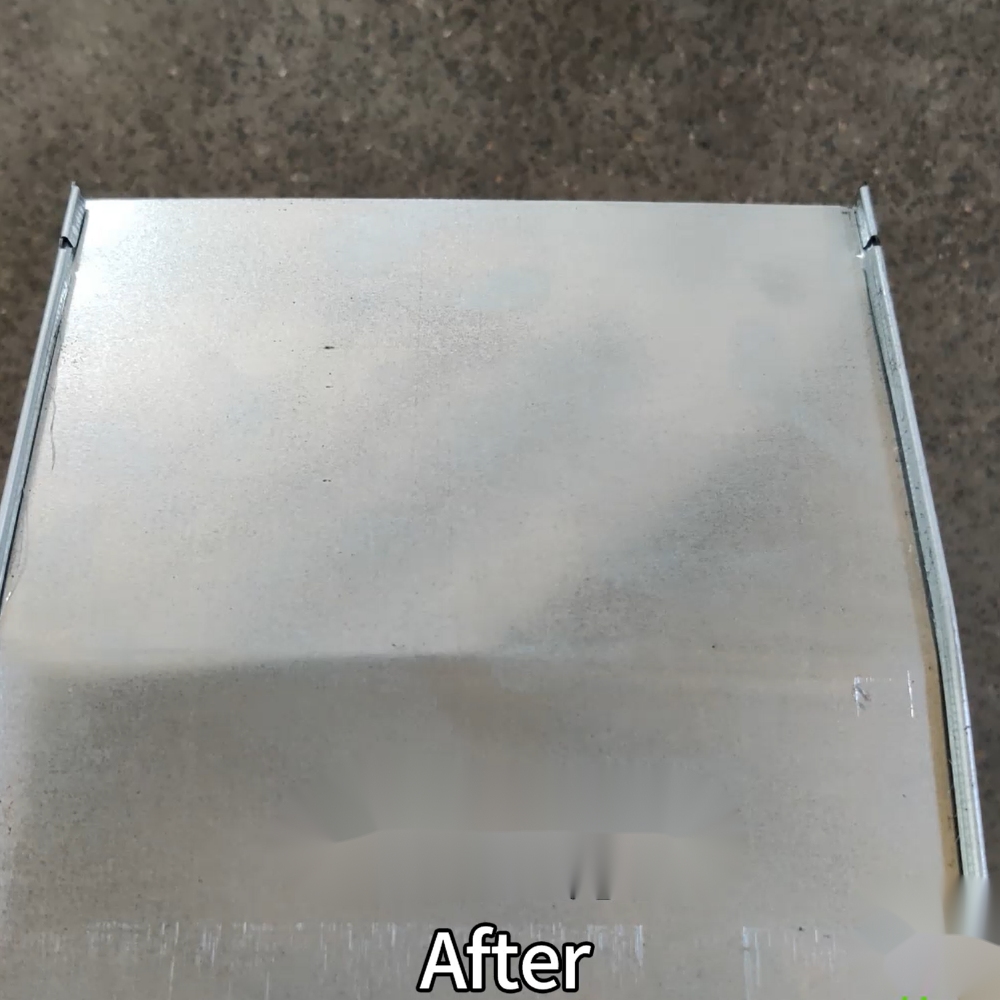

Complete the forming of centrifugal fan housing, because the surface of galvanized sheet and stainless steel material is not allowed to be scratched and scratched! We are equipped with a fully CNC servo blanking mechanism! Ensure that the fan housing is not damaged.

The centrifugal fan housing forming production line can process galvanized sheet and cold-rolled sheet with a wall thickness of 0.6-1.5mm; sheet width 300-1,300; metal sheet length 600-4000mm.

The efficiency can reach 20-40 pieces per hour, which is widely used in the metal shell forming production of purification fans, air conditioning centrifugal fans, dust removal industrial fans, fume purification fans, and light multi-wing fans, which greatly reduces labor costs and factory floor space! Realize unmanned forming production.

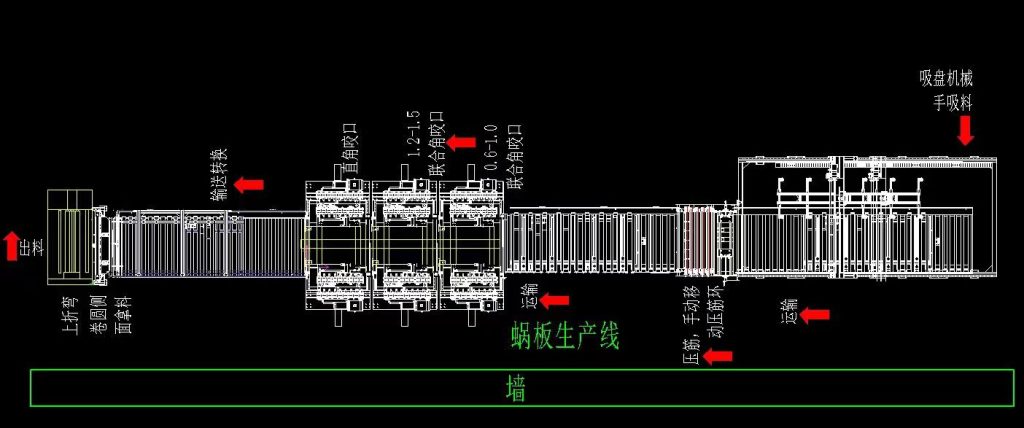

Centrifugal Fan Casing Forming Diagram

Feeding-Pressing- Hemming, Flanging,-Rolling-Unloading, etc.

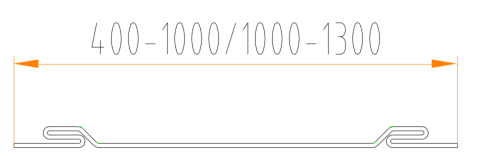

Centrifugal Fan Casing Forming Range

Material: stainless steel, galvanized sheet, cold rolled sheet

Material size

Width: 300-1300MM

Length: 600-4000MM

Thickness: 0.6-1.5MM

Efficiency: 20-40 pieces/H

Centrifugal fan housing hemming Finished Effect

Configuration

ALTRON Centrifugal Fan Housing Hemming Machine, with its CNC four-stick rounding machine, pneumatic bending machine, side panels pre-fastening machine, and CNC hemming machine, represents a pinnacle of engineering precision.

This assembly line of advanced machinery ensures the creation of fan housings that not only meet but exceed industry standards.

As technology continues to evolve, these machines stand as a testament to the harmonious collaboration between human expertise and cutting-edge automation, propelling manufacturing into a new era of excellence.

Fully automatic custom production line for centrifugal fan housings

We are currently customizing a fully automatic centrifugal fan casing forming production line for Guangdong Zhaoqing Detong Co., Ltd.

Fully automatic custom production line for centrifugal fan housing:

The centrifugal fan housing production line is a set of sheet metal processing equipment developed and designed by Altron engineers and technicians in accordance with Detong’s usage requirements and with reference to similar production lines. It can produce the processing and blanking of centrifugal fan housings, and the production line automatically completes the centrifugal fan housings!

Functions of the centrifugal fan housing production line:

- Suction cup manipulator,

- Bead pressing device,

- Flange forming device,

- Rolling device,

- Servo manipulator,

- Folding device, etc.

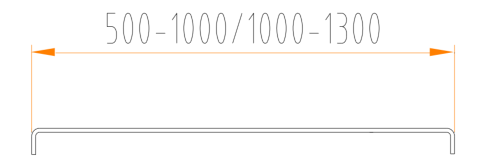

Basic parameters of the centrifugal fan housing production line:

- Material: galvanized sheet

- Thickness: 0.6-1.0/1.2-1.5

- Sheet width: 500-1000/1000-1300mm

- Sheet length: 600~4000mm

- Production efficiency: 45 seconds/piece

Process flow of the centrifugal fan housing production line:

Suction cup suction – conveying – clamping and pressing – conveying – forming – material passing – servo bending – manipulator feeding – rolling.

Schematic diagram of the centrifugal fan housing production line:

Centrifugal Fan Housing Forming Production Line Test Video

- At present, the production line is ready to be sent to Detong Industrial Fan Factory!

- It solves the forming of thin-plate housings of centrifugal fans of different sizes and specifications, greatly improving production efficiency!

- During this period, the production line solves the forming of different flange edges and realizes two bite methods on one production line!

- This production line is the first independently developed production line in the industrial ventilation fan industry.

- We work with engineers from Detong Industrial Fan Factory to improve the energy efficiency and production process of the production line!

- Altron always discusses with customers to meet real manufacturing and production needs! Adhere to the development direction of quality and practicality

Industrial Centrifugal Fan Housing Sample – Galvanized Sheet

|

Equipment name and model: |

CNC three-roller rounding machine |

| The main parameters | |

| Input power: | 380V, 50Hz three-phase four-wire |

| Control voltage: | 24V |

| Equipment power: | 4.5KW |

| Transmission mode: | CNC |

| Applicable product diameter: | 400MM |

| Applicable height: | 300MM |

| Applicable material thickness: | 0.4-1.5mm |

| Equipment usage function: | hoarding rounding |

|

Equipment name and model: |

CNC hemming machine |

| The main parameters | Equipment reference pictures |

| Input power: | 380V, 50Hz three-phase four-wire |

| Control voltage: | 24V |

| Equipment power: | 4.5KW |

| Transmission mode: | gas-liquid mixing |

| Applicable product diameter: | 400-700mm |

| Applicable height: | 300mm |

| Applicable material thickness: | 0.4-1.5mm |

| Equipment usage function: | Hemming |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.