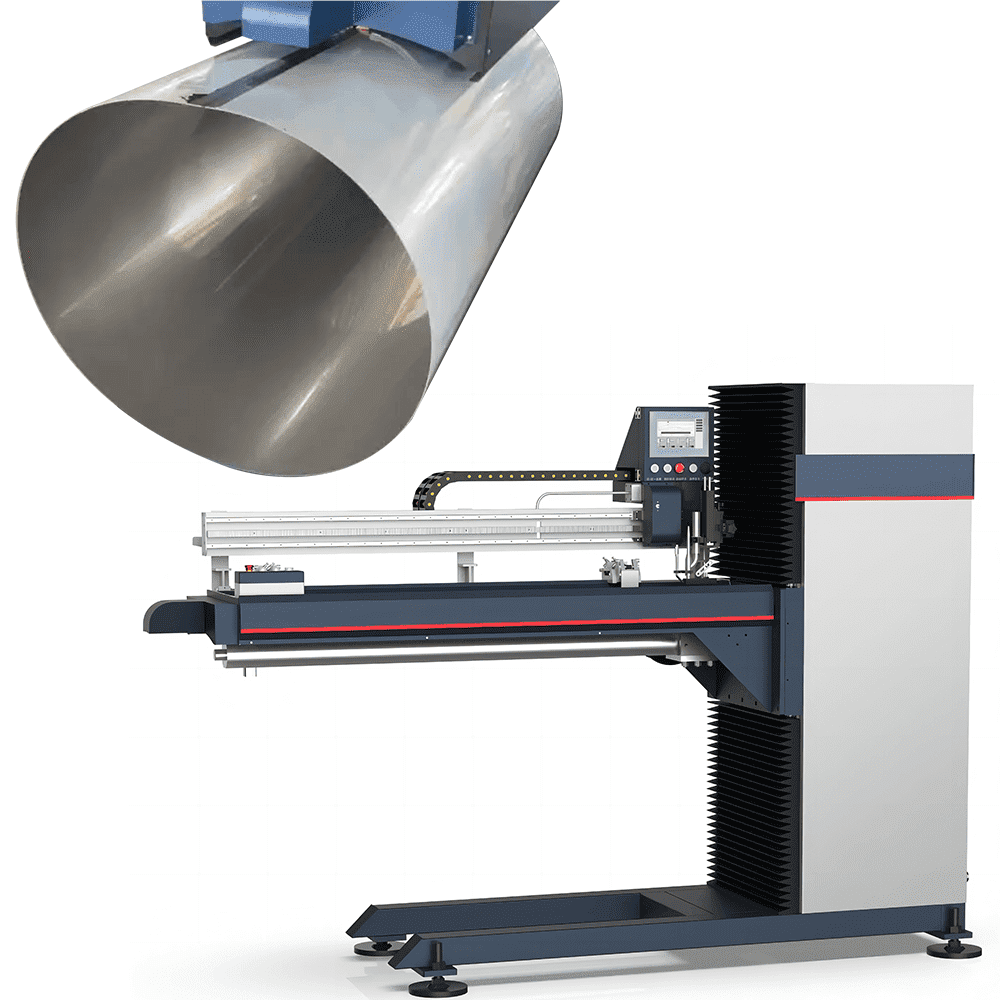

Auto-Seam Welding Machines

Seam Welding For Axial Fan Ducts

|

Machine Name |

Lifting Straight Seam Welding Machine |

|

Model |

AC-ZFH 1500G |

|

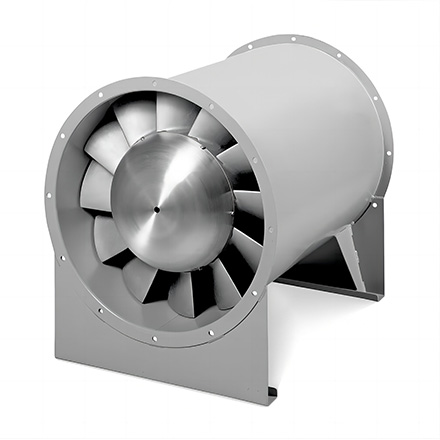

Application Industry |

Axial fan duct, water storage tank, cylindrical barrel |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

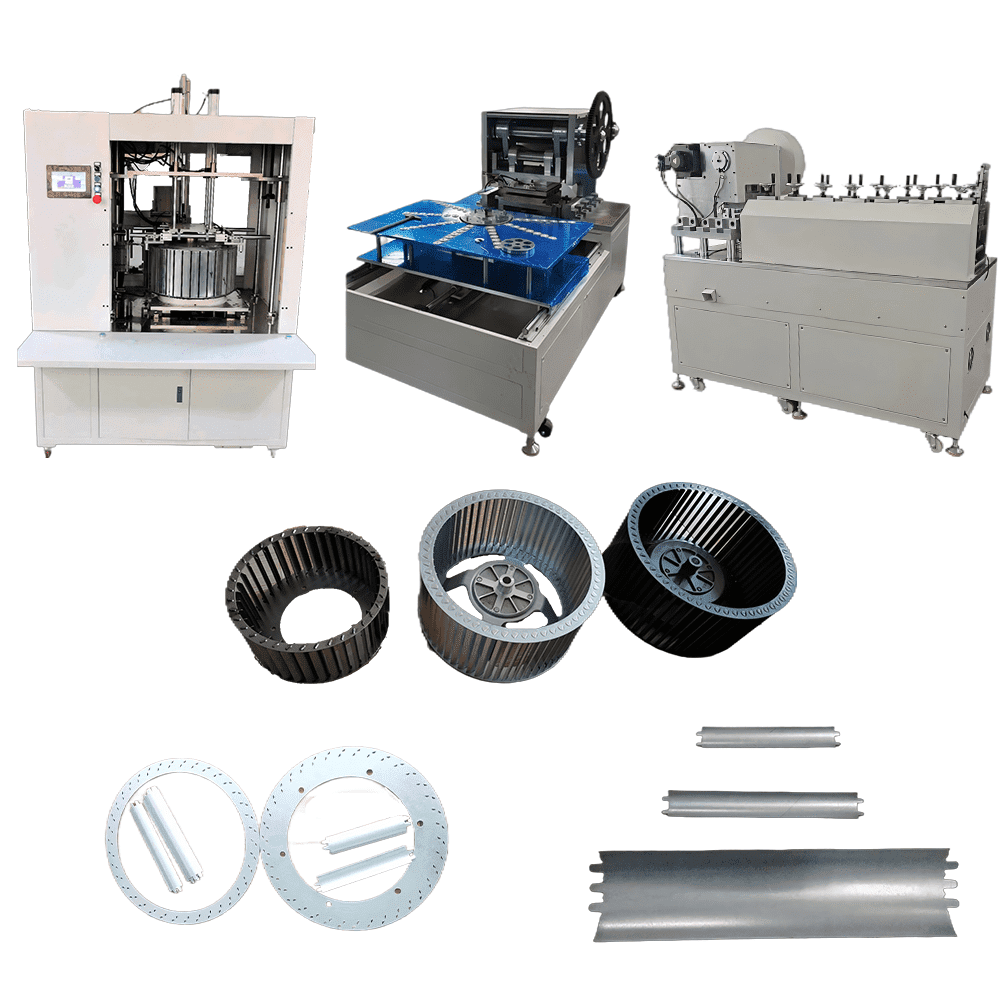

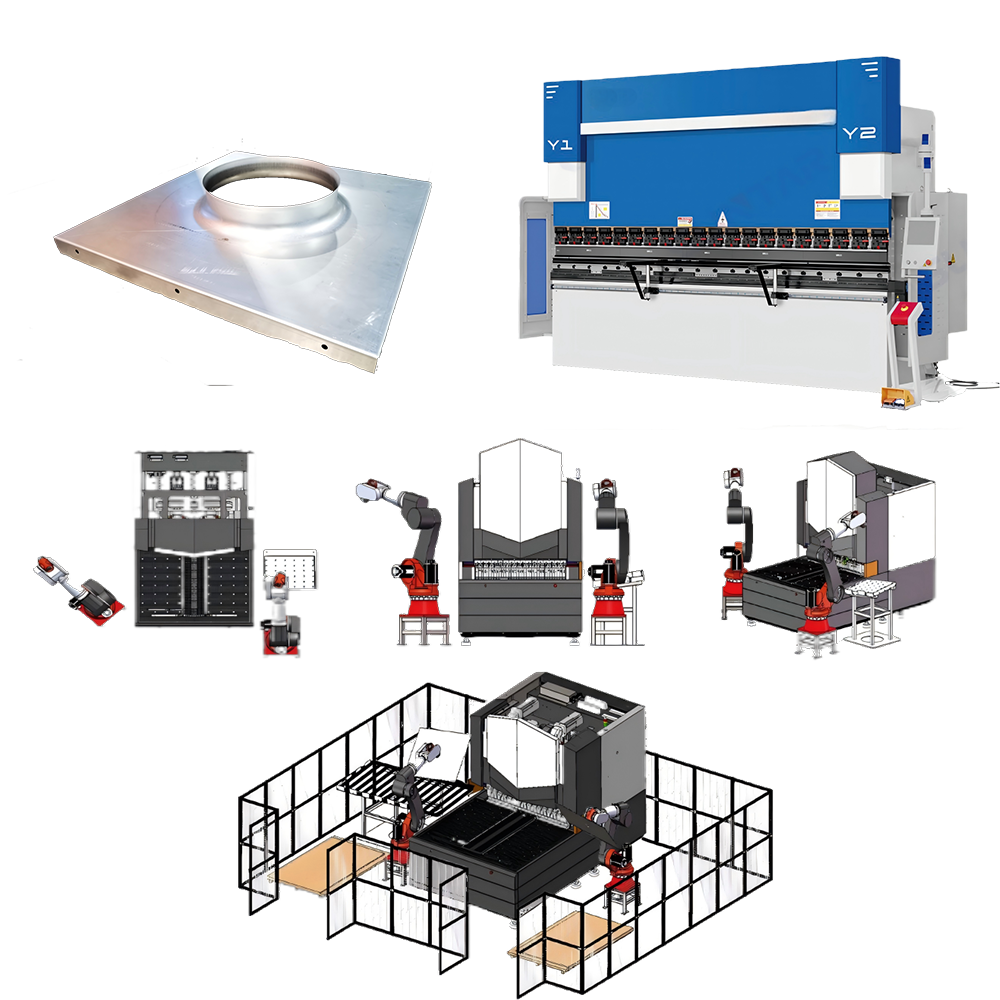

Axial Fans A-Z Project:

1 CNC Rolling machine 2 Seam Welding machine 3 Axial Flow Fans Forming Production Line, 4 CNC Flanging Machines,

- DETAILS

- PARAMETERS

- CUSTOMER TESTIMONIALS

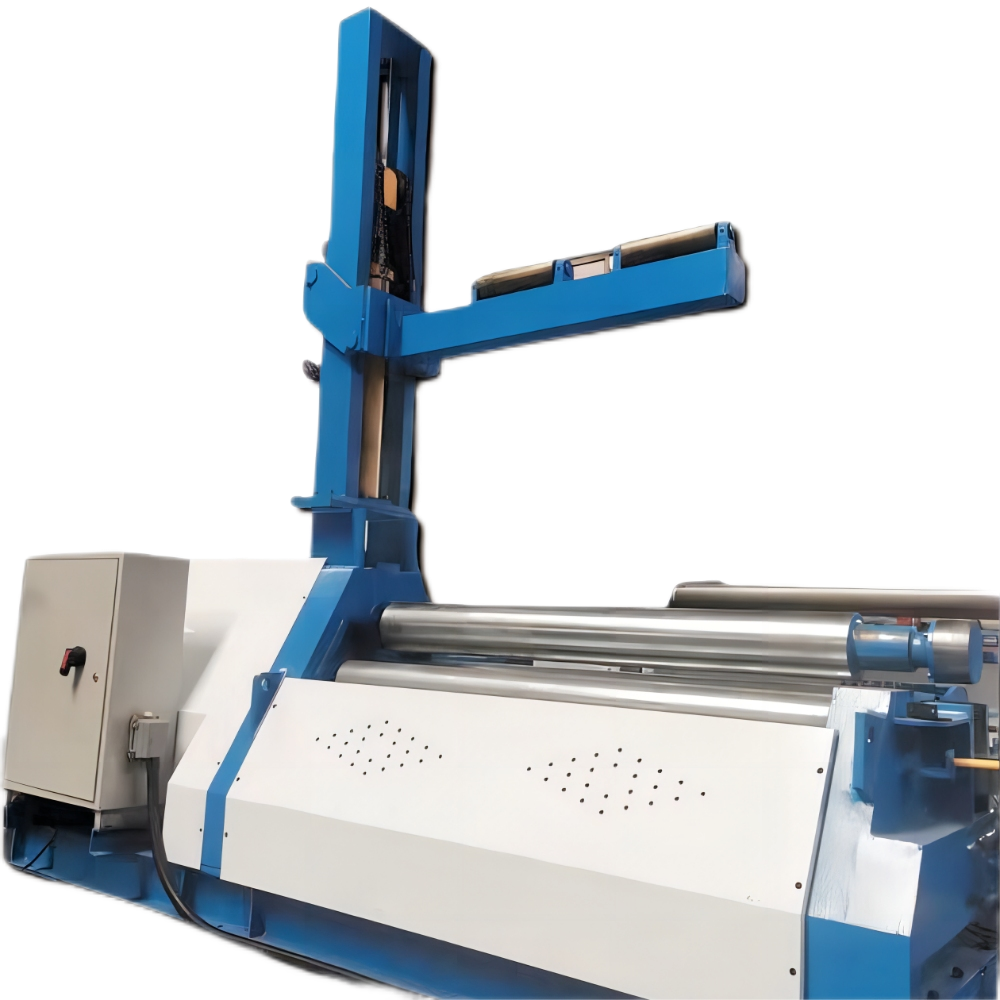

The lifting straight seam welding machine is designed for welding the longitudinal welding seams of cylindrical barrels. The axial flow fan duct with relatively thick metal plates must use a seam welding machine in the manufacturing process of the duct.

The production line mode or the single machine production mode can be selected according to the production situation!

Features Of Seam Welding Machine

- Specialized for straight seam welding of heavy fan cylinders, providing high-quality results.

- User-friendly touch screen display allows parameterized input and one-key operation, making it accessible to users of all experience levels.

- Equipped with a convenient feeding roll bracket for easy operation.

- The welding table features a lifting function, enabling straight seam welding of cylinders with various specifications.

Video Of Seam Welding For Axial Fan

Seam Welding Machine Description

- The Horizontal Lifting Straight Seam Automatic Welding Machine is a top-of-the-line, high-efficiency solution for welding non-deformable cylinders with a wall thickness ranging from 0.6mm to 3mm. It excels in butt joint longitudinal seam welding of cylinders, flat plates, or square boxes with one end open. Suitable for carbon steel, cold galvanized, and stainless steel materials, it offers the option of argon arc welding (with or without wire filling) or melting electrode gas TIG welding power sources, complemented by a longitudinal seam automatic welding system.

- The machine features a one-piece main shaft with built-in copper bars and split all-copper pressure plates. The main beam can be electrically raised or lowered, facilitating size adjustments of pipe fittings, enhancing feeding speed, and providing robust load-bearing capacity. Welding torch lifting employs pneumatic and truss lifting, ensuring precise positioning.

- The host control system utilizes PLC control for stable and reliable operation. Notable features include adjustable welding table height, an upgraded high-precision external positioning and centering device for improved convenience and durability, and fine-tuning capabilities for the welding torch in vertical, horizontal, left, and right directions.

- The welding torch traveling mechanism utilizes a pneumatic clutch method, enabling quick and accurate positioning without the need for touch screen control. Pneumatic tipping eliminates the need for manual operation. The machine supports continuous integral or segmental welding, offering excellent control precision and stability. TIG welding or MAG welding can be selected based on specific requirements.

- To ensure optimal welding results, the machine incorporates an airbag pressing device with flexible copper plate pressing for enhanced thermal conductivity. A mandrel-inserted bottom spindle, equipped with a safety device, guarantees proper depth of welding fusion. The welding torch is guided by TBI linear guide rail and TBI ball screw, ensuring stable welding performance. The feeding frame has universal travel, while the cantilever features electric lifting, and the welding torch is pneumatically adjustable in height.

The Difference of Seam Welding Machines

Parameter Table Of Welding Processes (For Reference)

TIG Welding Reference Table

| Material Thickness (mm) | Current (A) | Welding Speed (mm/s) |

| 0.4 | 25-30 | 3.5-4 |

| 0.6 | 55-65 | 7-9 |

| 0.8 | 70-80 | 7-9 |

| 1.0 | 90-100 | 7-9 |

| 1.2 | 110-120 | 7-9 |

| 1.5 | 140-150 | 7-9 |

| 2.0 | 160-180 | 7-9 |

Gas Shielded Welding Reference Table

| Material Thickness (mm) | Welding Wire Specifications | Current (A) | Voltage(V) | Welding Speed (mm/s) | Swing Width (mm) | Swing Speed (mm/s) |

| 2 | 1.0 Welding wire | 90-100 | 16.5-18 | 8 | 3 | 15 |

| 2.5 | 1.0 Welding wire | 115-125 | 19-21.5 | 8 | 3 | 15 |

| 3 | 1.0 Welding wire | 130-135 | 20-22 | 8 | 3 | 15 |

| 4 | Gap 2mm | 140-145 | 22-24 | 6.5-8 | 4 | 15 |

| 5 | Gap 2mm | 140-150 | 22-25 | 5.7-7 | 4 | 15 |

Home Page Matters:

- 1. Before using the machine, preliminary preparations are required, such as checking whether the movement of each axis is smooth, whether the positioning is accurate, and whether there is shaking or abnormal noise;

- 2. Check whether the ventilation is smooth and whether there is air leakage;

- 3. Do not stand under the lifting arm to prevent safety accidents;

- 4. Non-professionals are strictly prohibited from performing maintenance work when the power is on. If there is a problem, you must first consult a professional and wait for a reply before continuing to work;

- 5. The equipment must be grounded before use.

Video of Air Duct Rolling Welding Flanging Production Line

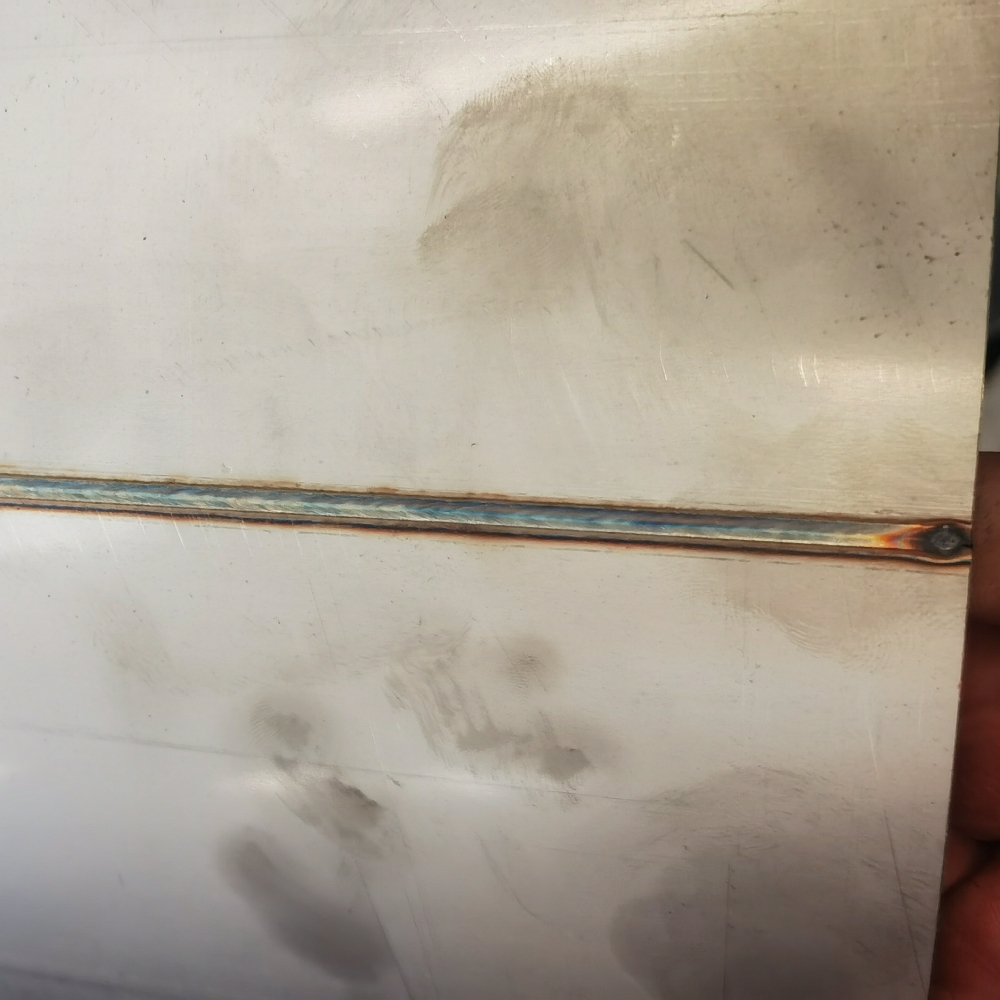

Welding Machine Finished Effect

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Lifting Straight Seam Welding Machine in our fabrication shop, and it has exceeded our expectations. The adjustable lifting mechanism allows us to weld a variety of workpiece sizes with ease.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The machine’s precise welding capabilities and user-friendly control system have significantly improved our welding efficiency and produced consistent, high-quality welds.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

We have been using the Lifting Straight Seam Welding Machine to weld straight seams in our metal pipes, and it has greatly improved our production process.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The machine’s adjustable welding height accommodates different pipe sizes, and its precise welding capabilities ensure consistent weld quality. It has helped us increase efficiency and meet our customers’ demands effectively