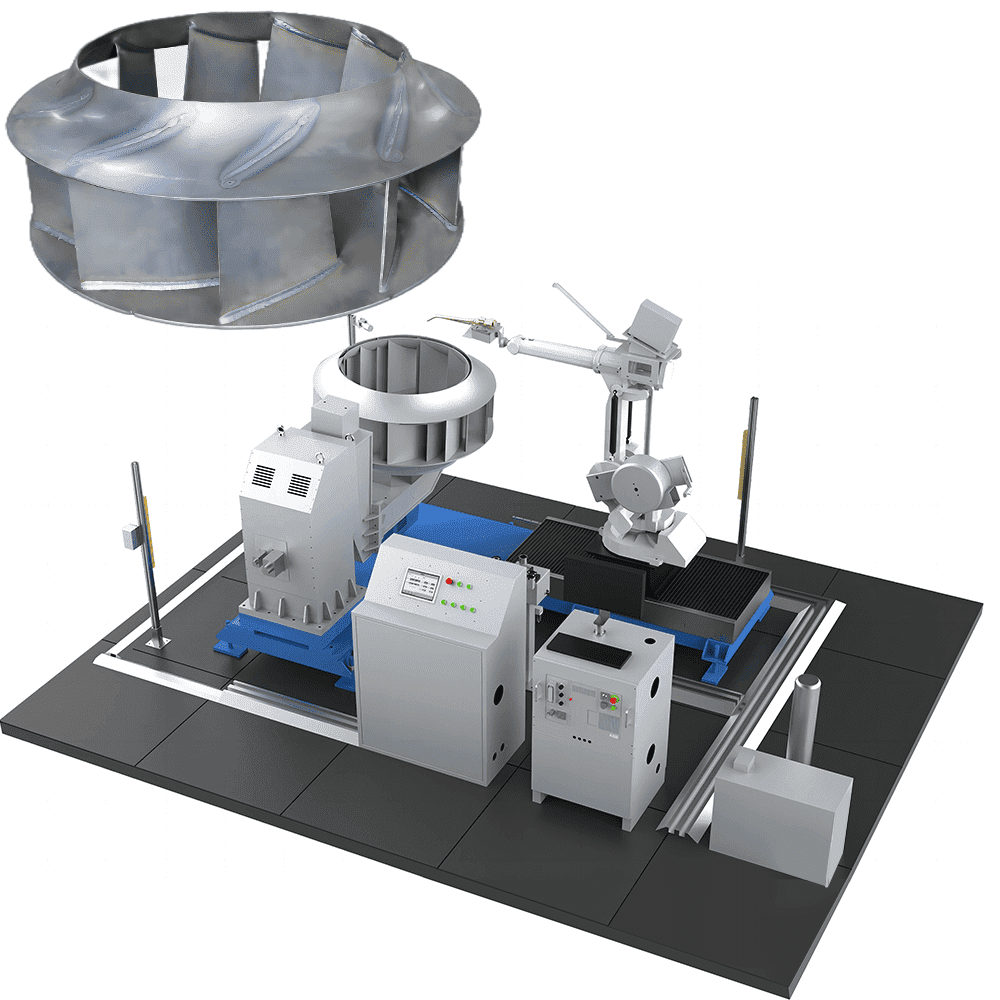

Welding Robot Machine For Centrifugal Fan Impeller

Welding For Centrifugal Fan Impeller ,Housing, Axial Fan Ducts

|

Machine Name |

Welding For Centrifugal Fan Impeller |

|

Model |

AC-YL (Camera, AI, Auto weld identification & Correction) |

|

Application Industry |

Centrifugal , Axial Fan , aluminum, carbon , stainless steel impellers, Duct |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

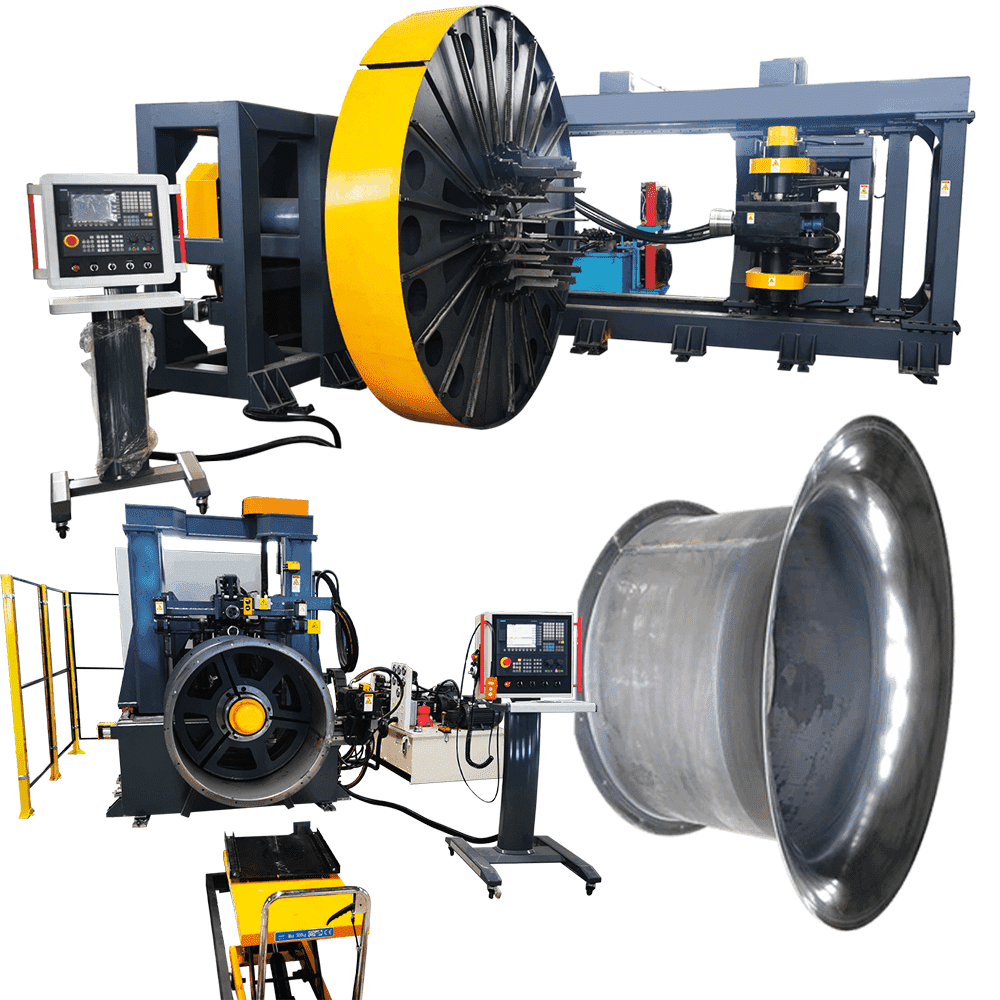

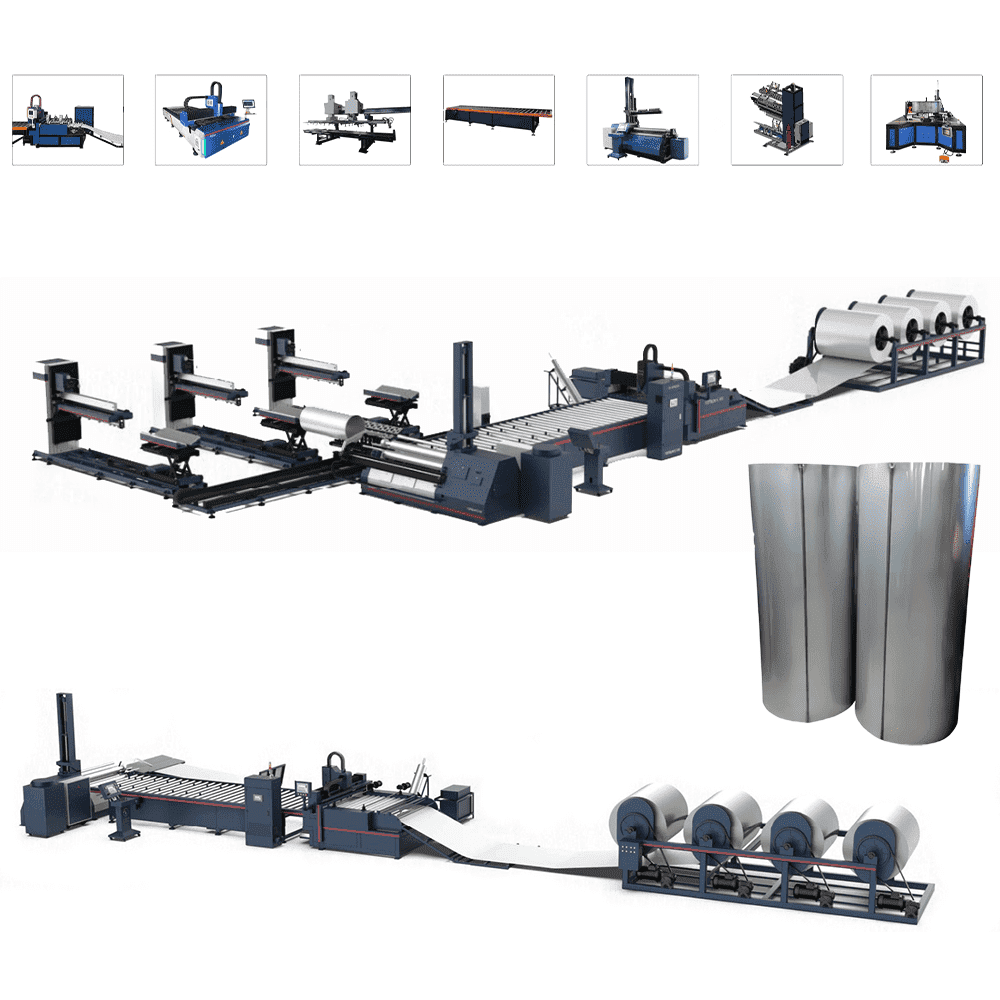

Industrial Fans A-Z Project:

1 CNC Spinning Machine 2 CNC Flanging Machines, 3 Axial Flow Fans Forming Production Line, 4 CNC Rolling machine,5 Seam Welding machine 6 AI Automatic Welding,

- DETAILS

- PARAMETERS

- CUSTOMER TESTIMONIALS

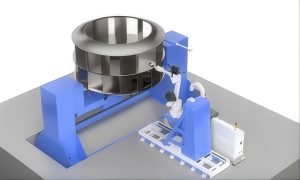

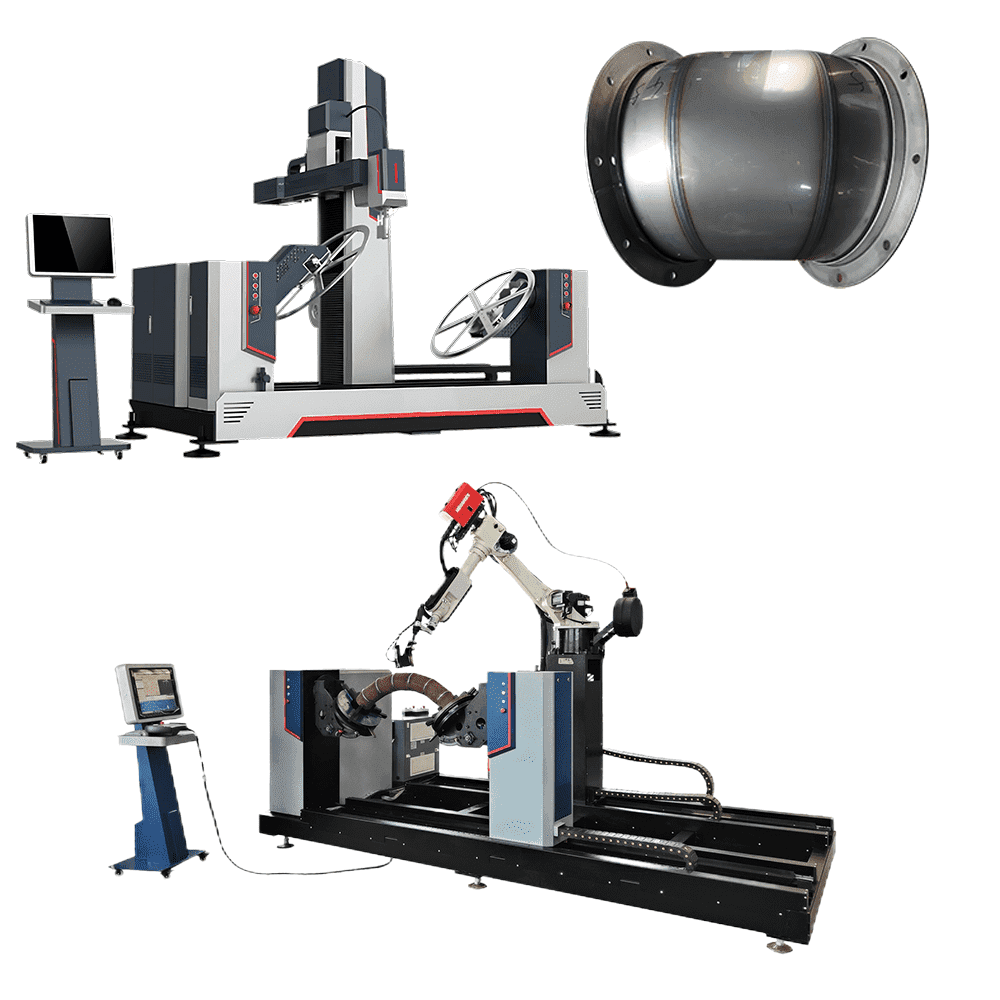

Introducing Altron’s centrifugal blower impeller welding robot to simplify the welding manufacturing process of centrifugal blower impellers. The quality of the centrifugal fan impeller determines the performance and energy efficiency of the industrial fan, and is a core component!

Traditional automatic welding equipment cannot track the weld in real time and correct the welding trajectory to achieve true automatic welding, so manual welding is basically used! The assembly of the impeller and the blades cannot be consistent, and the teaching programming method cannot be applied to impeller welding!

The laser vision-guided centrifugal fan impeller automatic welding robot automates the fan impeller, fan tube and other components, reduces the number of welding workers, and improves the welding quality and welding efficiency. After welding is completed, the weld strength is guaranteed to be consistent, the appearance is beautiful, and no manual grinding is required.

Centrifugal Fan Impeller Welding Video

Industrial Fan Impeller Range:

Impeller diameter: 300-3800 MM

Impeller height: 80-2400 MM

Impeller weight: 300-3800 MM

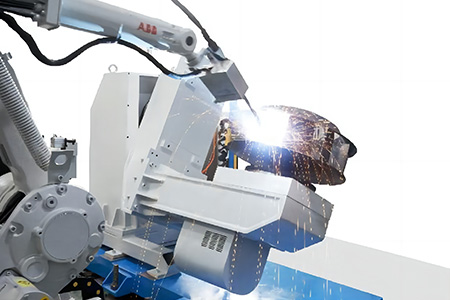

Robot: ABB & KUKA

Impeller assembly: Blade spot welding machine or manual spot welding tooling

Altron can customize welding solutions according to the impeller

The visual welding robot completely solves the problems of labor-intensive traditional fan manufacturing, low-end fan quality, and difficulty in mass production!

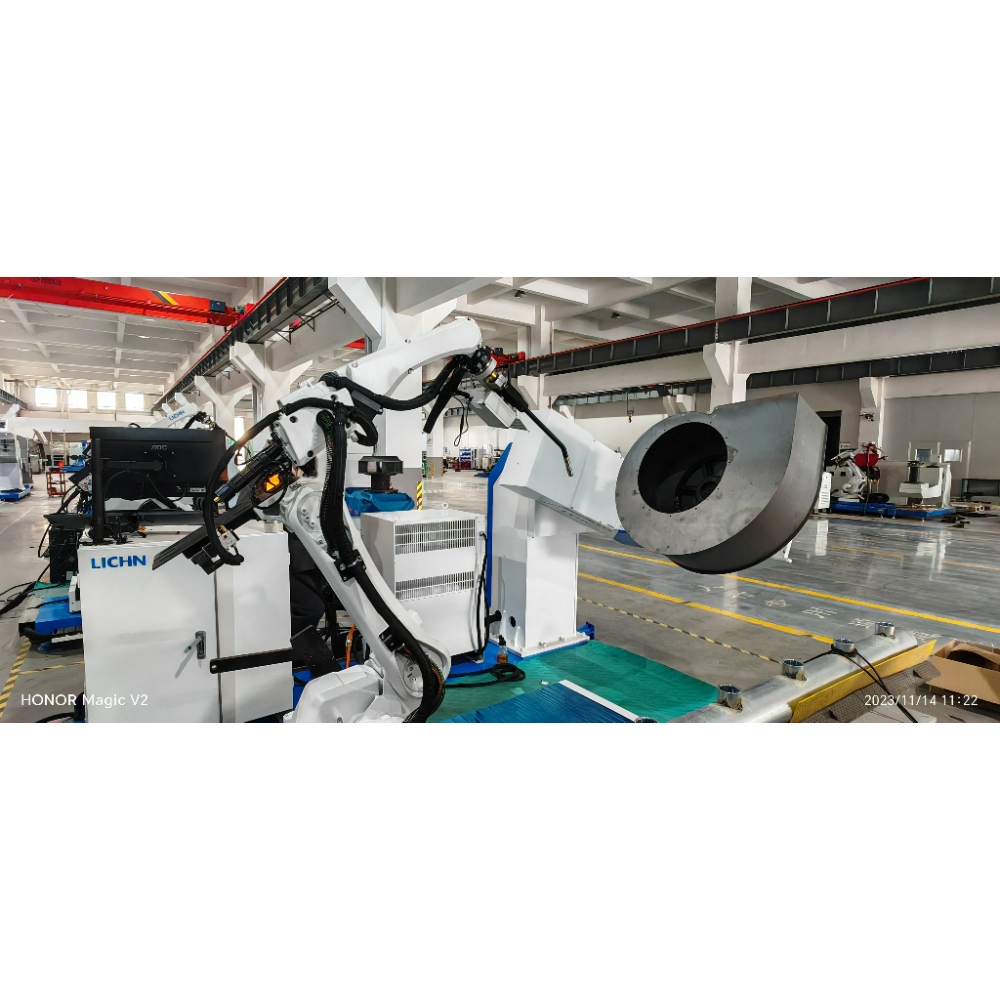

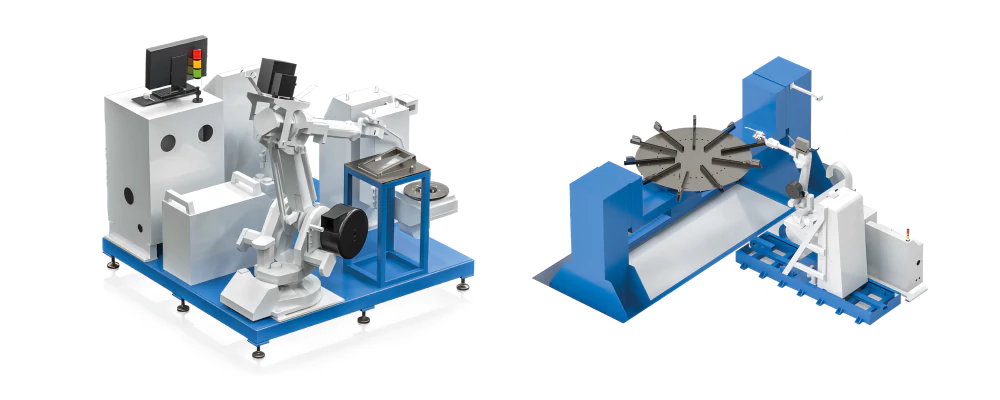

Description of Centrifugal Fan Impeller Welding Machine

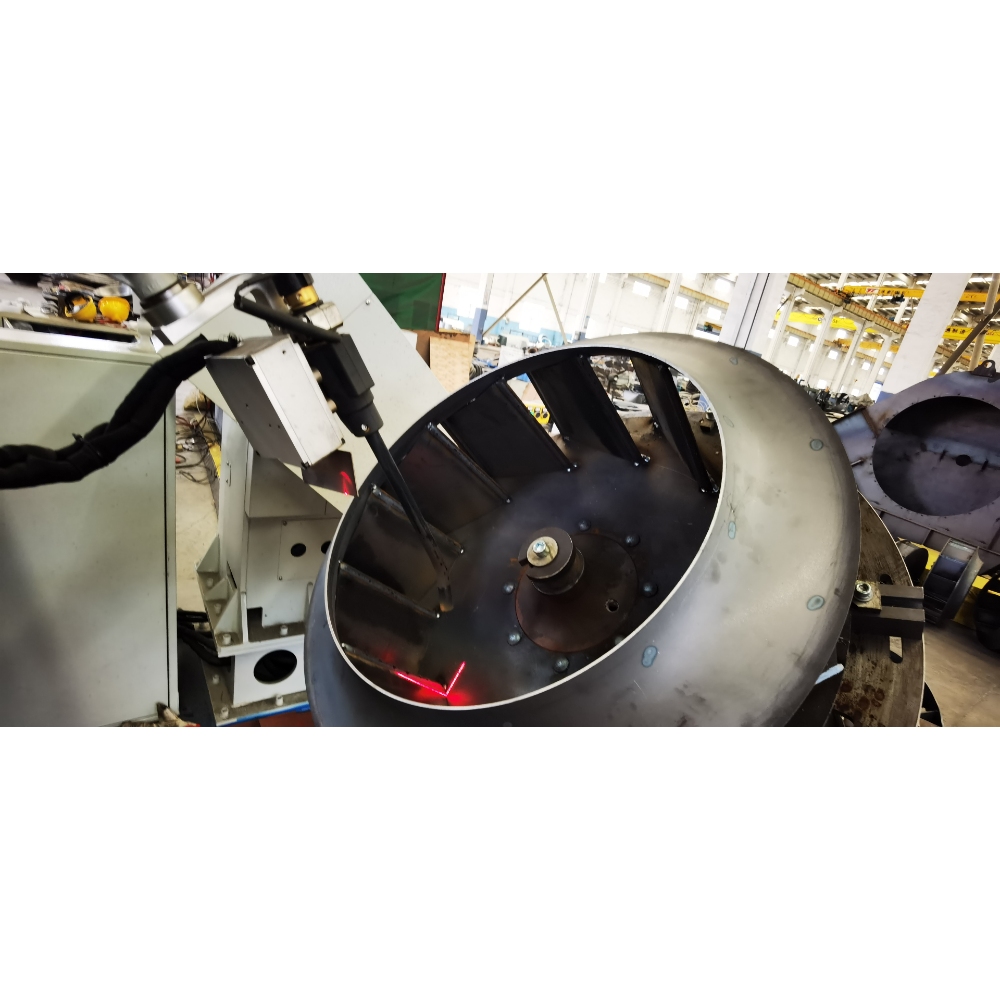

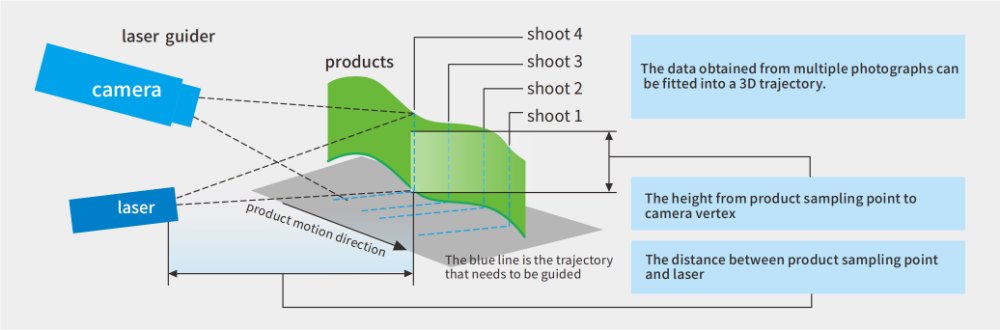

How does a robot identify the weld location of a centrifugal fan impeller?

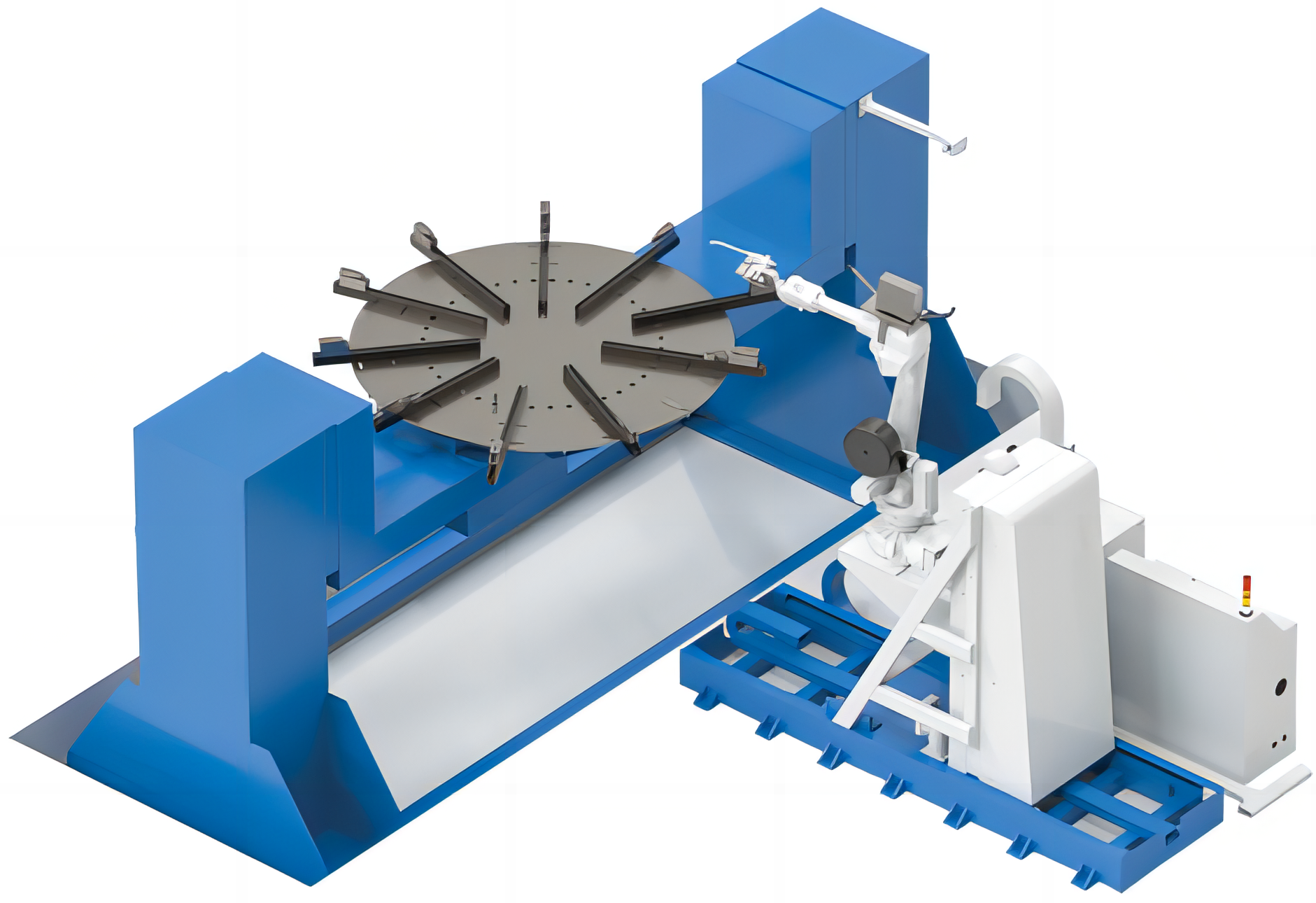

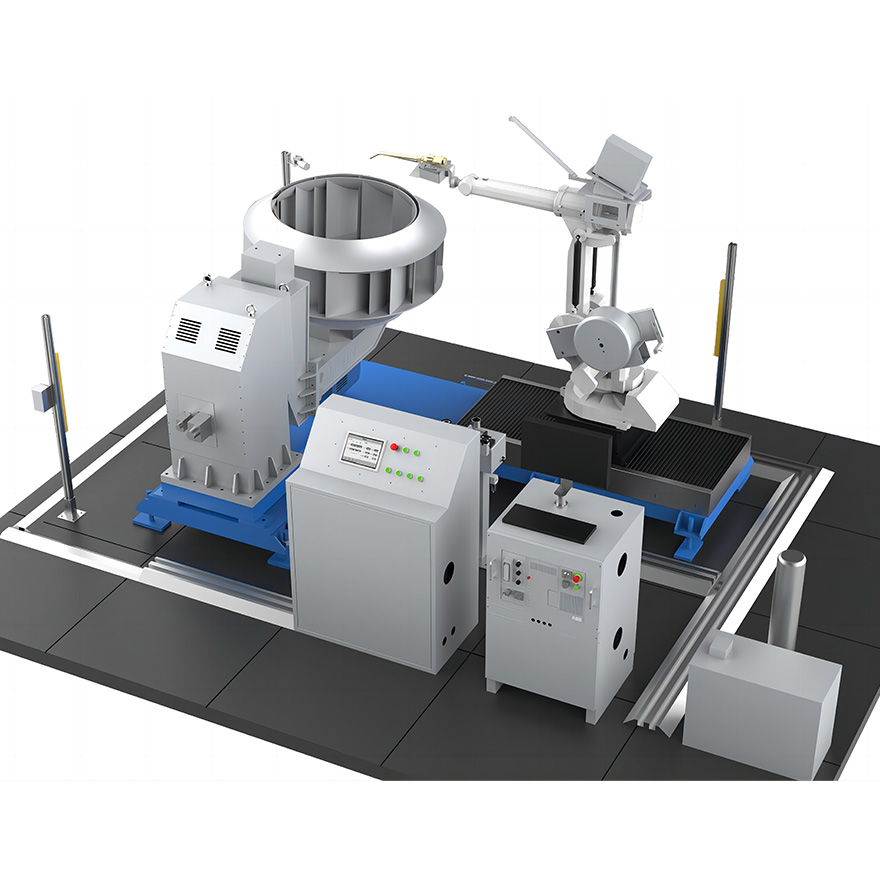

The automatic welding apparatus for impellers consists of several key components, including the ABB welding robot system, a two-axis transducer, a laser vision guiding system, a welding system, a gun clearing system, and a safety protection system. The laser vision system controls the welding trajectory by accurately guiding each weld seam using 3D coordinates and welding posture information. It continuously adjusts the welding trajectory to compensate for any spot welding deviations on the blades.

This equipment brings together the human-machine synergy, overcoming the issues associated with previous robot training methods and quickly identifying the weld seam for an optimal welding perspective. Real-time adjustments to the welding offset are made, ensuring the best welding results for subsequent weld seams.

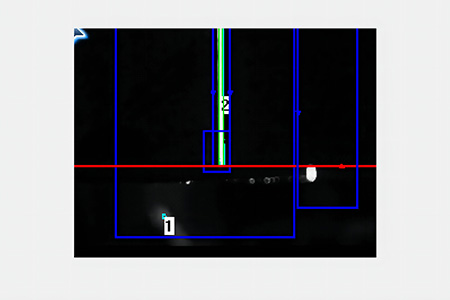

Industrial camera & camera imaging diagram

Camera parameters of centrifugal fan impeller welding machine

|

|

| Frame rate | 135fbs |

| Pixel clock frequency | 80MHz |

| Camera tap | 2 |

| Grayresolution | 8bit |

| Fixed analog noise | <1DN RMS@8bit |

| Exposure time range | 10us-335ms |

| Analog gain | n/a |

| Digital gain | 0.1to 15.99(Fine Gain) |

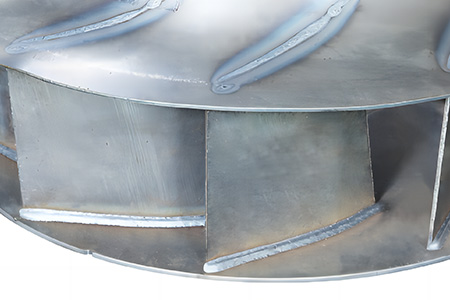

Automatic Welding Impeller Vs Manual Welding Impeller

Industrial Fan Metal Welding Solution-Customized welding Service For Axial & Centrifugal Fans

- Altron Industrial Fan Metal Welding Solution: (Axial Fan & Centrifugal Fan)

- Axial Fan Motor Bracket Scanning Welding

- Axial Fan Cylinder External Bracket Scanning Welding

- Axial Fan Cylinder Guide, Installation Base Welding Whole Process

- Axial Fan Impeller Blade Spot Welding Assembly

- Axial Fan Impeller Scanning Welding

- Customized Dual-station Centrifugal Fan Housing Welding

- Customized Dual-station Robot Welding Trapezoidal Base and Centrifugal Fan Frame

- Industrial Fan Manufacturer Welding Factory

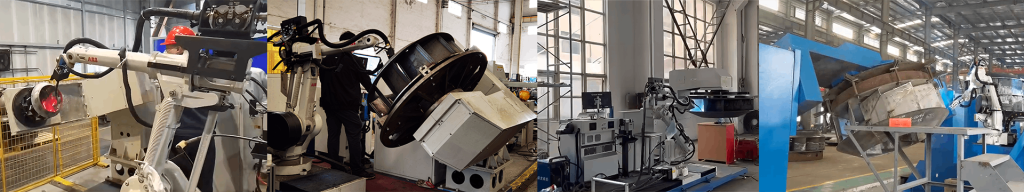

Impeller Welding Machine In Industry Fan Manufacturer Factory

Impeller Welding Machine Video In Korea

Impeller Welding Machine Video In Detong

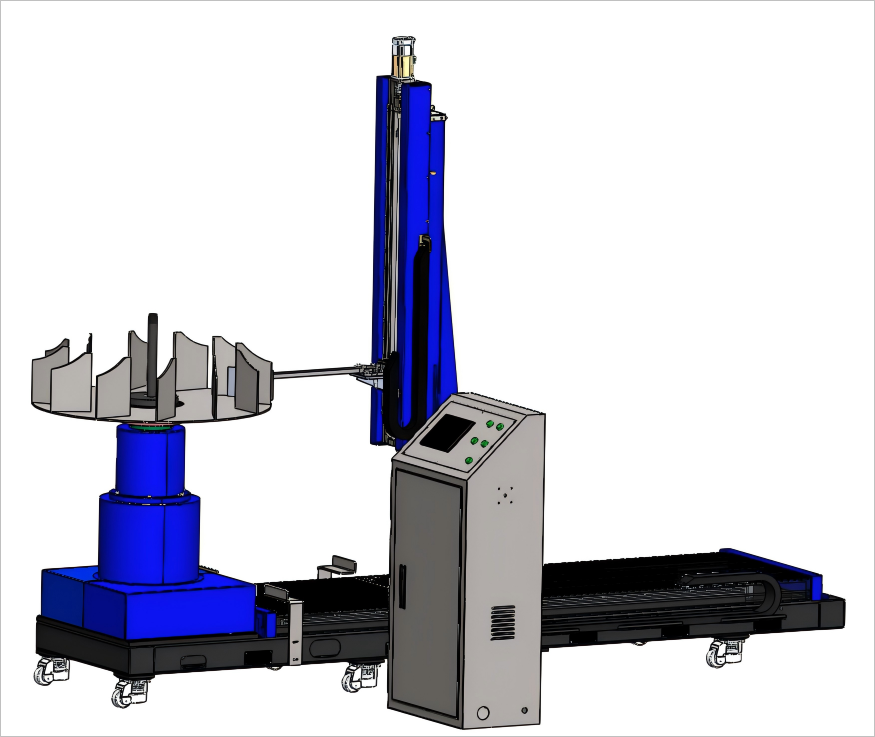

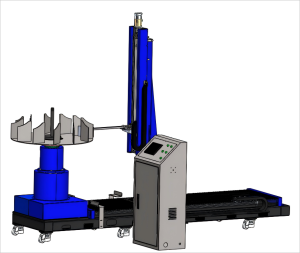

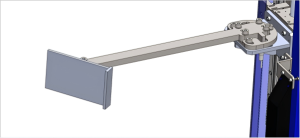

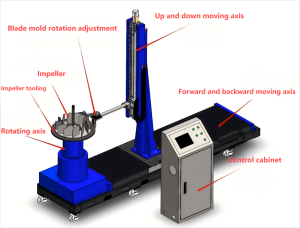

Industrial Fan Impeller Blade Assembly Spot Welding Machine

The front and rear axes, upper and lower axes, and rotating axes of the spot welding machine can be flexibly adjusted, and the turntable drives the workpiece to automatically rotate, eliminating the need for manual scale marking and assisting manual insertion and spot welding.

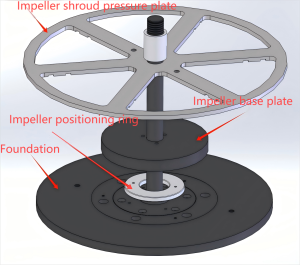

3 Ways To Assemble Centrifugal Fan Impellers

Advantages & Disadvantages Of Assembling Centrifugal Fan Impellers:

- Laser Line Drawing: low efficiency, poor consistency, high requirements for manual welding; low cost!

- Positioning Pin: complex processing technology, high cost; good consistency!

- Impeller Spot Welding: simple operation, high angle accuracy, low tooling cost; cooperate with impeller welding production!

Impeller Manual Welding Effect & Machine Welding Effect

Impeller Spot Welding Machine Schematic Diagram

Blade Assembly Spot Welding Machine Video

Impeller Spot Welding Machine Parameter Table

| Machine Size | Length | 2750 MM |

| Width | 640 MM(not include cabinet) | |

| Height | 2170 MM | |

| Weight | 620 KG | |

| Machine Travel | Front and rear axis travel | 1200 MM |

| Upper and lower axis travel | 800 MM | |

| Rotating axis travel | 360° | |

| Processing Range | Maximum diameter of single inlet impeller | 1600 MM |

| Minimum diameter of double inlet impeller | 240 MM | |

| Maximum impeller weight | 1500 KG | |

| Machine Accuracy | Rotating axis reverse clearance | 0.5 MM |

| Rotating axis coaxiality | 0.2 MM |

Parameters Of Vision Guided Fan Impeller Welding Machine

| Item | HYL03-0.1T | HYL01-0.5T | HYL02-1T | HYL04-2T | HFT01 | HFT02 |

| Machine Dimension (L*W*H)MM |

2000*2000*1800 | 3500*2200*2000 | 3700*2500*2100 | 3700*2700*2100 | 6000*7000*3000 | 6000*7000*3000 |

| Machine Mass | 1500 KGS | 3500 KGS | 5000 KGS | 6000 KGS | 9200 KGS | 10800 KGS |

| Dia. Of Impeller | 300-600 mm | 400-1260 mm | 400-1600 mm | 400-2000 mm | ≤3.8 M | ≤3.8 M |

| Height. Of Impeller | ≤600 mm | ≤1000 mm | ≤1000 mm | ≤1000 mm | ≤2.4 M | ≤2.4 M |

| Load (With Tooling) | 100 KG | 500 KG | 1000 KG | 2000 KG | 5000 KG | 8000 KG |

| Power Supply | Equipment: AC220V; Welding M/C: AC380V |

Equipment: AC220V; Welding M/C: AC380V |

AC380V | AC380V | AC380V | AC380V |

| Centrifugal Fan Impeller WeldingRobot Structure |  |

|||||

Application Of Welding Robots On Industrial Fans

Basic Performance Parameters of ABB Robot

Electrical Configuration

| Equipment name | Contents description | Brand | |

| Welding robot system | Robot | IRB1410 | ABB |

| Robot control cabinet | IRC5 Compact | ||

| Teaching box | Flex Pendant | ||

| Welding power supply | Special for 350 robot | Aotai | |

| Wire feeder | Dual-robot wire feeder | ||

| Communication module | DeviceNet module | ||

| Welding torch and anti-collision sensor | 350A, the length of gun body extends 250mm | Rihao | |

| Gun clearing wire cutting device | Automatic nozzle cleaning, gun cleaning, wire cutting and silicone oil spraying function in welding torch | TRM | |

| Welding seam laservision guider | Correction of deviation between actual and programmed positions of reference points on workpiece surface | XINJE | |

| Hand-eye calibration system | High-precision hand-eye calibration board, calibration table and software | XINJE | |

| Dual-axis servo turnover location shifter | Turnover main driven box(2.3KW servo motor and Planet reducer) | Carrying weight 350KG (with craft equipment) | Customized |

| Turnover slave driven box | |||

| Horizontal rotary power box(1.5KW servo motor and Planet reducer) | |||

| Base of location shifter | |||

| Fixture placement connection plate | |||

| Electrical part | PLC control system | ||

| Main control table | XD3 | XINJE | |

| Work position operation table | Touch win HMI | ||

| Control wire and cable bridge | Schneider button | ||

| Wireless module | / | ||

| Light screen and positioning laser | Remote control | ||

| Welding fixture (wind blade has been spot welded) | / | Customized | |

| / | |||

| Accessories | Robot base | / | |

| Matching equipment placement frame | / | ||

| Robot external walking axis | Trip 800mm | ||

Parameter setting interface of teaching machine impeller welding system

According to the kind of impeller product, welding voltage, current, and speed. offset can be changed. after the setup is complete. The parameters may be imported and saved into a project, and subsequent welding processes can use them directly depending on the kind of product being produced without requiring additional setup.

HMI

Manual and automatic operation modes can be selected and simple parameters can be set.

Field Application

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

I recently received the welding equipment and I must say that I am extremely satisfied with my experience so far. The training video provided was comprehensive and helped me understand the setup and operation of the machine. The after-sales service has been exceptional, with patient and helpful support staff guiding me through any questions or concerns I had.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

I was pleasantly surprised by how simple the equipment was to operate. With the clear instructions and intuitive interface, I was able to get the machine up and running quickly. The user-friendly design made it easy for me to grasp the controls and make adjustments as needed.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The efficiency of the equipment has exceeded my expectations. It has significantly reduced labor costs and improved productivity in our welding processes. The quality of the welds produced by the machine is excellent, and I no longer have to worry about inconsistencies or uncertainties that were common with manual work. This has increased the acceptance of our products among our customers.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

I am extremely pleased with the performance of the equipment and the support provided by the company. I highly recommend this welding system to others in need of efficient and reliable welding solutions.