Robotic Laser Welding Machine

Welding For Rectangular Duct- Laser, Argon Arc, Gas Shielded

|

Machine Name |

Robotic Welding Machine(Angle iron punching & 4-gun flange welding) |

|

Model |

AC-FGJ (weld tracking) |

|

Application Industry |

Oil smoke, air purification, medical materials, pharmaceuticals, chemicals, stainless steel rectangular welded ducts, etc. |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Air Ducts A-Z Project:

1. Rectangular duct welding 2. Elbow duct welding 3. Duct forming

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

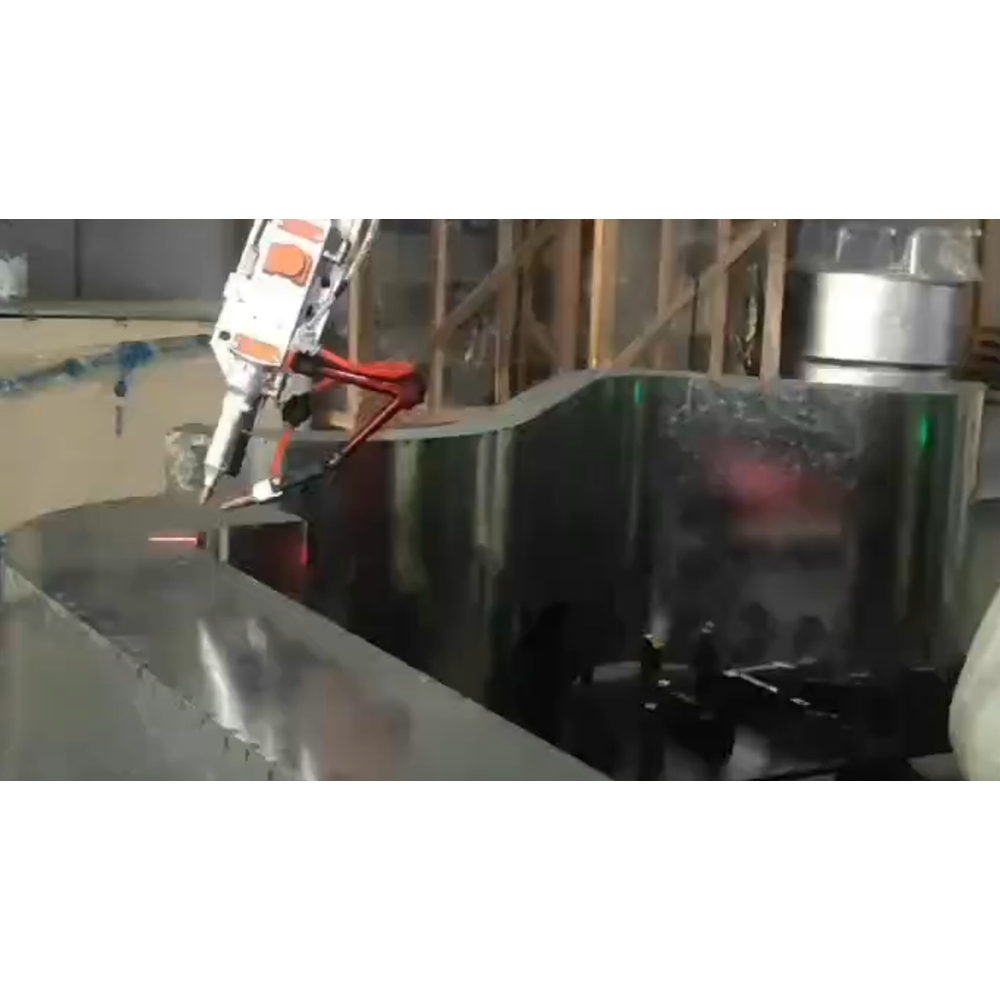

The main function of the robot laser welding machine is to replace the manual welding process of stainless steel and galvanized sheet air ducts. The quality of welding and labor costs are constantly rising. This machine can solve the difficulties of automated production of air ducts; especially in the application of oil fume ventilation ducts, air purification ducts, medical waste discharge ducts, pharmaceutical product ventilation ducts, chemical ventilation ducts, stainless steel, galvanized sheet rectangular or heterogeneous welding ducts.

Welding For Rectangular Air Duct Video

Advantages Of Robotic Laser Welding Machine For Rectangular Air Ducts

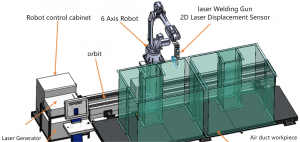

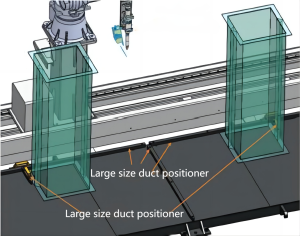

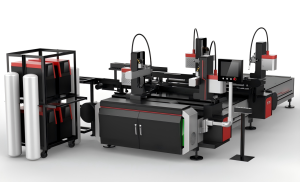

- Robotic Welding Machine consists of a six-axis robot ground track, a duct welding platform, a visual query system, a control system, etc.

- It can meet the needs of horizontal and vertical automatic welding of duct flanges.

- The double-station duct welding platform is equipped with a movable robot ground track, which can greatly meet the needs of products of various specifications. No human intervention or manual operation is required during the welding process; only product positioning and product loading and unloading are required.

- Through program parameterized input and visual laser detection of welds, find the weld position. And automatically generate welding tracks.

- This equipment is controlled by a touch screen with start, stop, emergency stop and other buttons.

Common Application Areas Of Welded Air Ducts

- Oil fume ventilation duct,

- air purification duct,

- medical waste discharge duct,

- pharmaceutical product ventilation duct,

- chemical ventilation duct,

- stainless steel rectangular welding duct, etc.

Introduction Of Robotic Laser Welding Machine

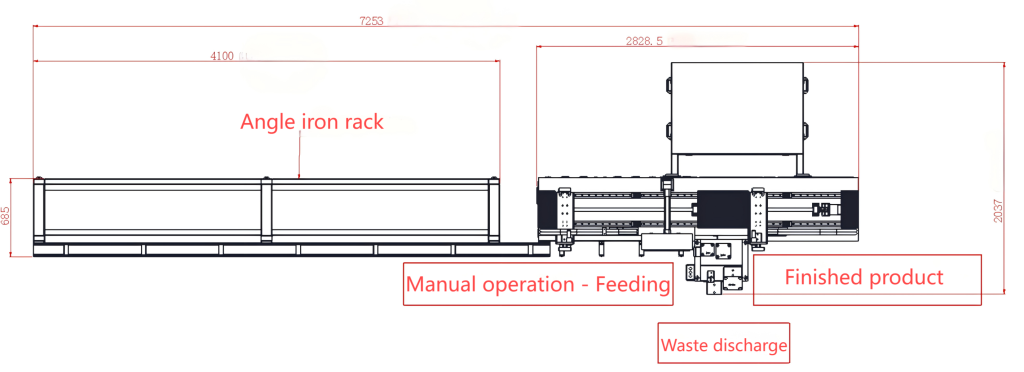

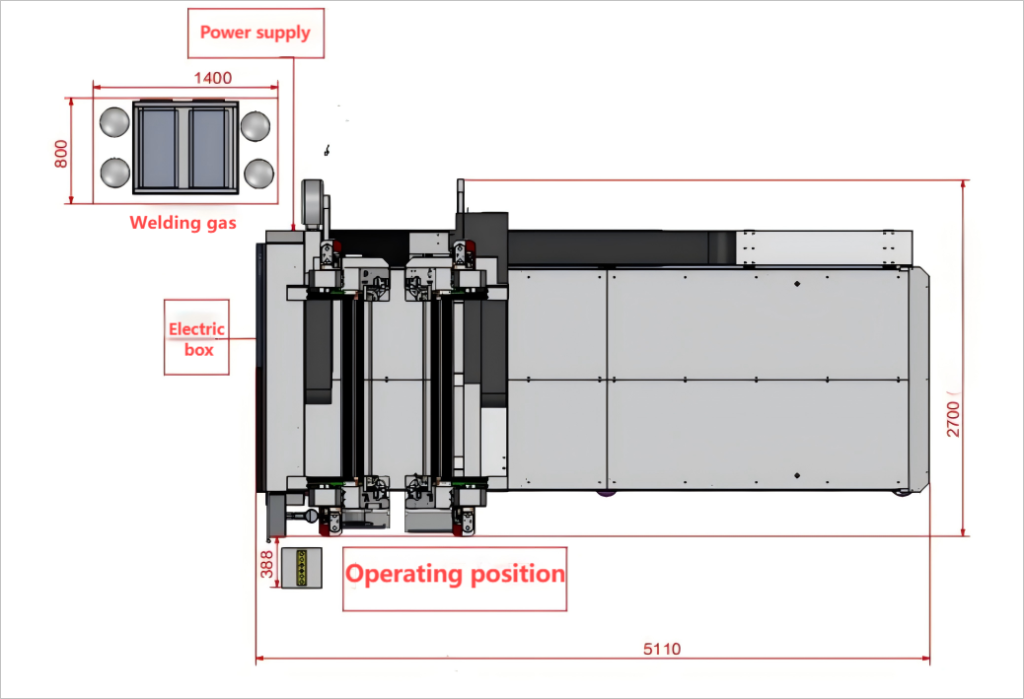

Machine structure intention

Rectangular duct can scan the position of automatic welding

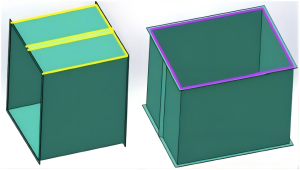

Positions where air ducts can be welded

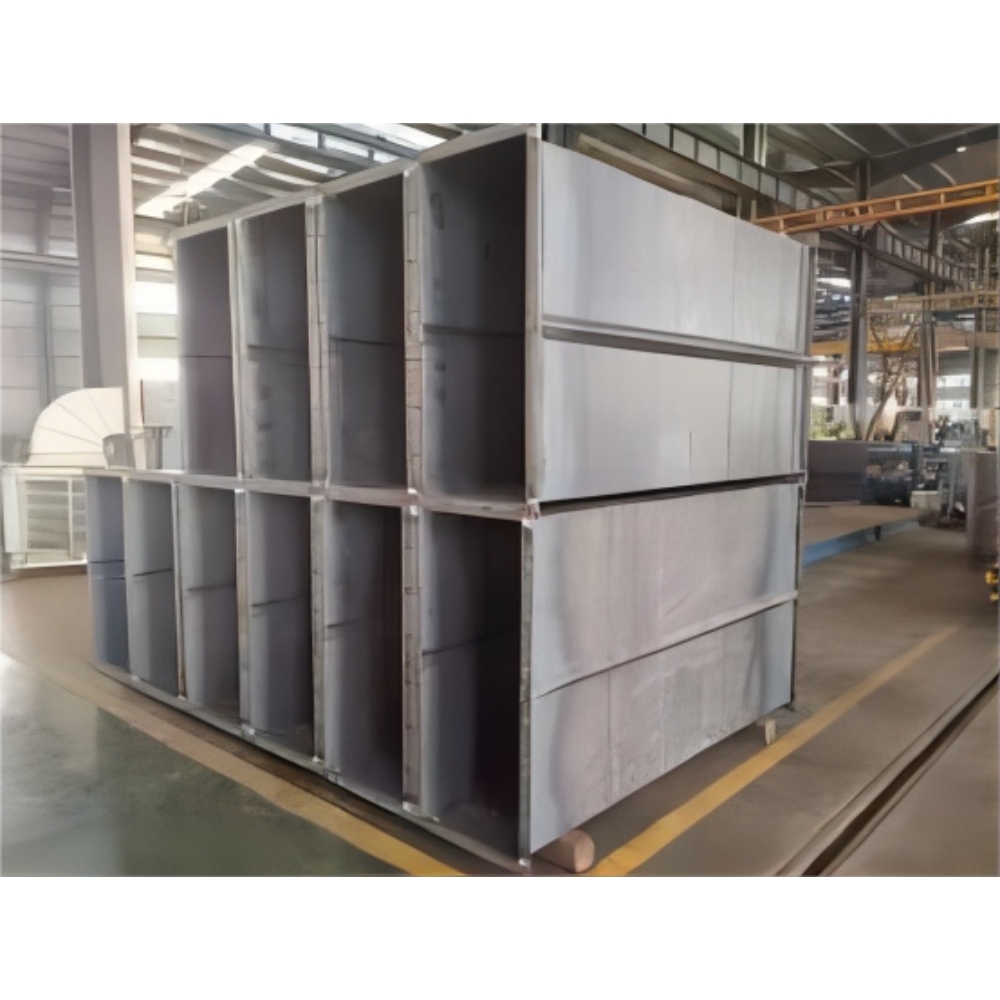

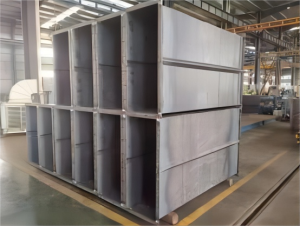

Common rectangular duct

- Inside the duct flange

- Outside the duct flange

- Outside the duct closure

Special shaped air duct

- Ducts with multiple arcs

- Embedded rectangular ducts

- Duct Connectors

The process of laser welding heterogeneous rectangular duct

Production Video Of Welding Air Duct

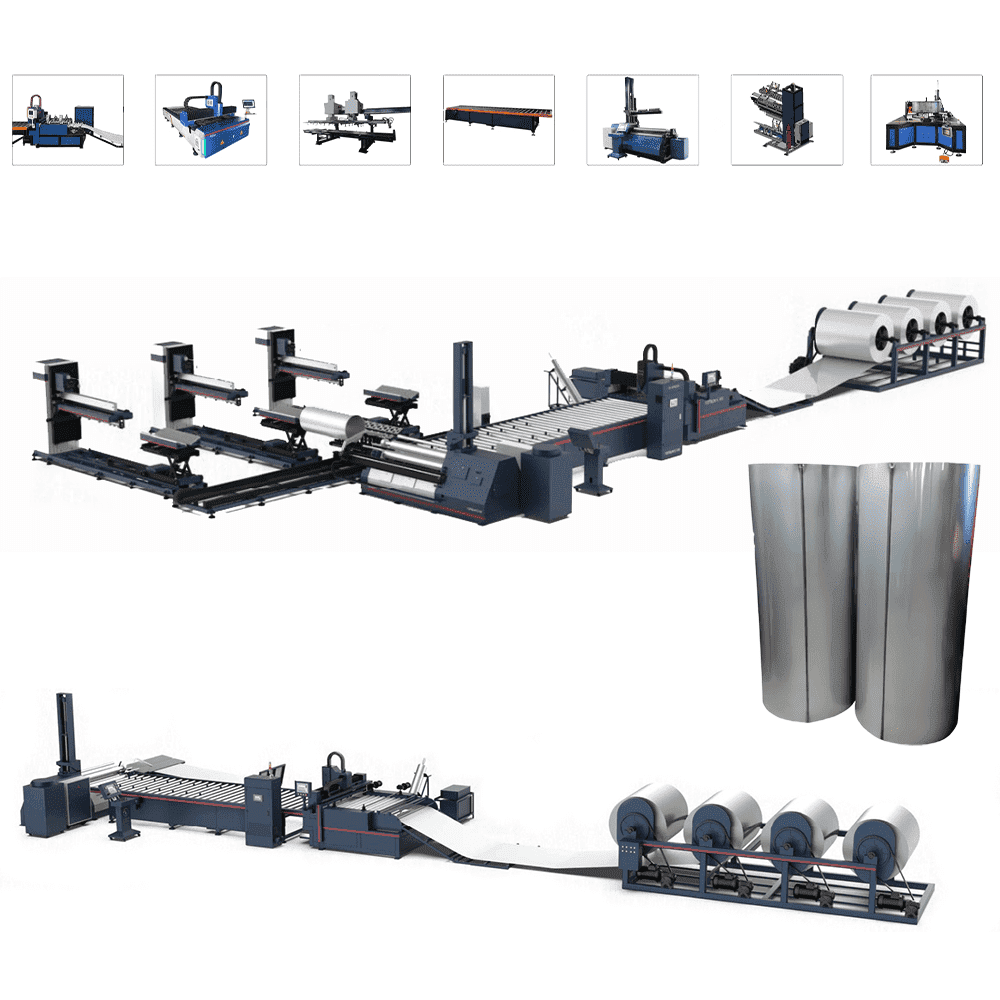

Rectangular Air Duct Production Machine:Robot Welding For Air Ducts, Angle Iron Flange Punching, Flange 4-Gun Welding;

There is a very important process link in the welding duct processing process! That is Welding. Whether it is welding rods or welding wires, attention should be paid to matching with the metal base material!

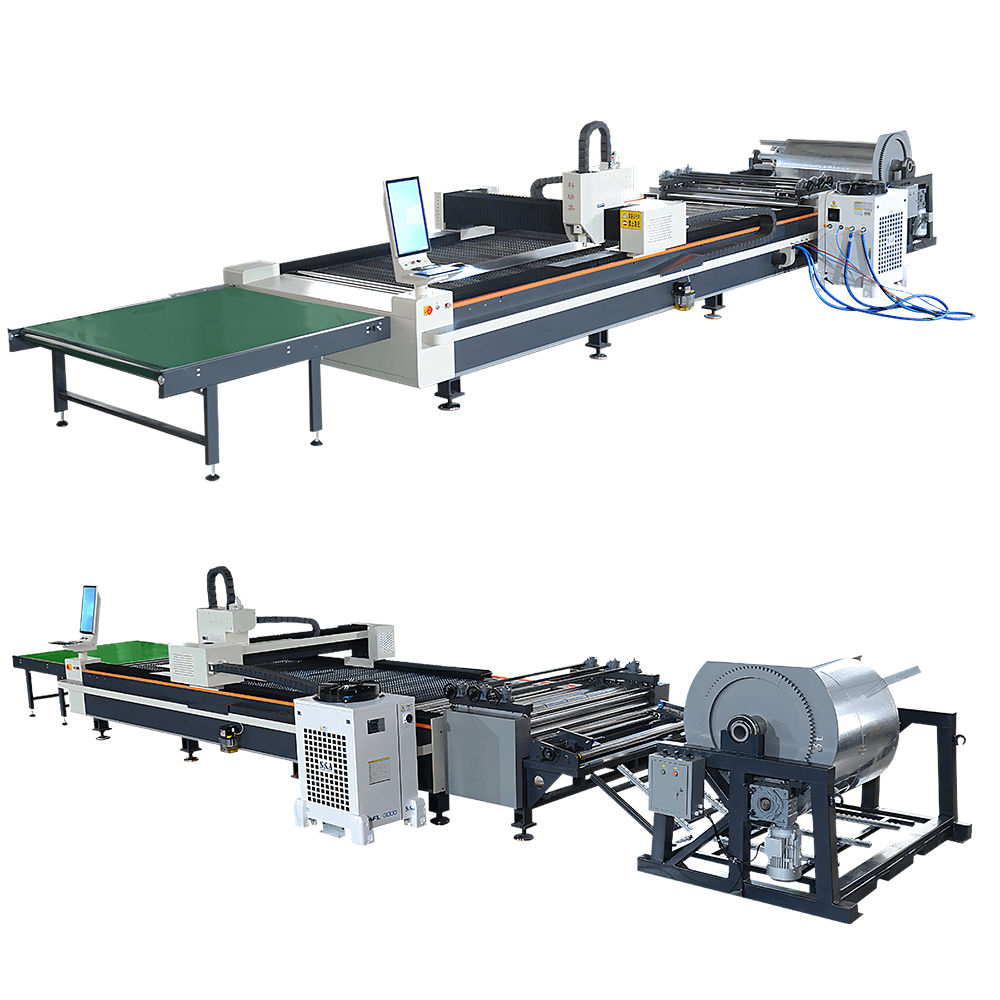

Before welding, clean the welding parts and surroundings of carbon steel ducts, stainless steel ducts, and galvanized sheet ducts; align the welding parts of the ducts to ensure that the weld gap is uniform or the misalignment meets the requirements.

Combined with the customer’s customized duct requirements, select the appropriate welding process, among which argon arc welding or carbon dioxide gas shielded welding has the advantages of high welding quality, high efficiency, and small deformation! It is widely used. Among them, when welding more stainless steel air ducts, laser welding can be preferred, which is more efficient and the weld is more beautiful!

In order to reduce welding deformation or stress in the process of manufacturing metal air ducts, a reasonable welding sequence should be adopted. After welding, strict visual inspection or tool inspection should be carried out to ensure that the weld meets the requirements. Finally, the weld surface is treated to improve corrosion resistance.

If you encounter welding or forming problems during the manufacture of rectangular metal ducts, please contact Altron!

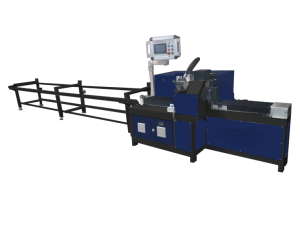

Angle Iron Punching Machine (servo)

Angle Iron Punching Machine Diagram

Angle Iron Punching Machine Parameters

Angle Iron Processing Range

| Angle Iron Specifications: | 30~50 MM |

| Angle Iron Thickness: | 1~5 MM |

| Angle Iron Materials: | Carbon steel, Stainless steel, Galvanized |

| Punching Type | 4.3 Tangent Hole, 9.5*13 MM, Long slot hole ( can be customized according to requirements) |

| Chamfer Type: | 45° bevel |

Angle Iron Punching Machine parameters

| Rated Total Power: | 10 KW |

| Power Supply: | 380/50 V/HZ |

| Max Operating Speed: | 700 mm/s |

| Punching Efficiency: | 6m angle iron: 60~80s per iron (varies according to the number of punching holes) |

| Programming Mode: | Automatic nesting |

| Control System: | 2 Axes self-developed |

| Repeat Positioning : | ±0.2 mm |

| Stroke: | A axis effective stroke 1000mm (Feeding) B axis effective stroke 420mm (discharging) |

| Transmission Mode: | Motor + Reducer + Ball Screw + Guide Rail Imported From Taiwan |

| Servo Motor : | 0.75KW HuiChuan |

| Low voltage Electrical: | Relay/contactor Schneider |

| Hydraulic System: | Oil tank capacity 360L, oil pump motor 11KW, high-speed air cooler, 7 sets of oil cylinders |

| Machine Weight: | 2500 Kg (Equipment footprint 7300*2000*1800 mm) |

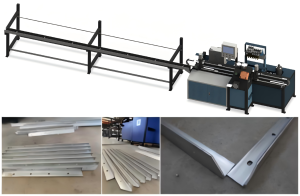

Duct Angle Iron Flange Automatic Welding Machine(4 Guns)

Angle Iron Flange Welding Machine Diagram

Angle Iron Flange Welding Machine Parameters

Duct Flange Processing Range

| Minimum Rectangular Flange: | 120×120*50 mm |

| Maximum Rectangular Flange: | 3500*1500*50 mm |

| Applicable Profile Thickness: | 1.0-5.0 mm (Customizable Thickness) |

Duct Flange Welding Machine Parameters

| Rated Total Power: | 25kw |

| Power Supply: | CNC 220V±10% 50Hz ; Welding machine 380V±10% 50Hz |

| Welding Equipment: | 4 welding power supplies + 4 welding guns + 4 wire feeders |

| Clamp Positioning: | 4 sets of devices |

| Welding Gun Module: | 8 sets of control devices |

| Operation Speed: | 6000mm/min |

| Welding Gun Lifting Distance: | 100mm |

| Welding Efficiency: | 1 per 10 seconds |

| Control Motor: | 12x drive motor-Hechuan servo drive |

| Repeat Positioning Accuracy: | ±0.2mm |

| Welding Power Supply: | Megmeet or Panasonic |

| Reducer & Running Track: | Planetary Reducer & Taiwan |

| Built-In Air Pipe | High temperature Sanis |

| Machine size: | 5200*2700*1600mm (With unloading device) |

|

Total Power

|

Power Supply

|

Repeat positioning precision |

Welding Efficiency

|

|

16kw

|

380v/50hz

|

+/-0.05mm

|

8-15mm/S |

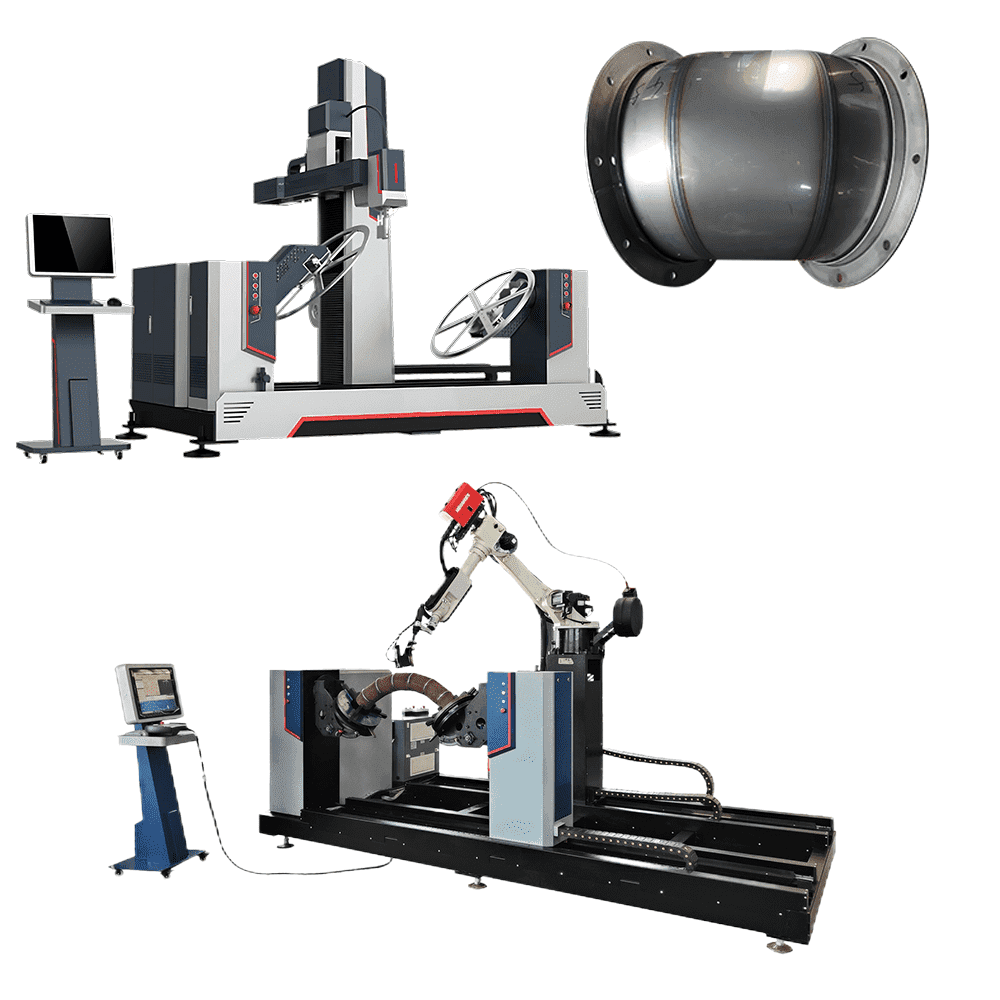

Robot Air Duct Laser Welding Robot Parameters

- Workpiece material: stainless steel/galvanized sheet

- Material thickness: 0.6 – 2 mm

- Processing stroke: 200×200 – 1500×2000 mm height 1250 mm

- Welding type: laser welding

- Welding methods: horizontal welding, vertical welding, 2D sensor laser positioning

- Overall dimensions:5100*2100*3000 mm length, width and height)

-

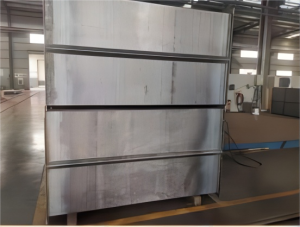

Welding effect of rectangular air duct

Rectangular duct flange welding effect

Rectangular duct connection effect

Welding Effect

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.