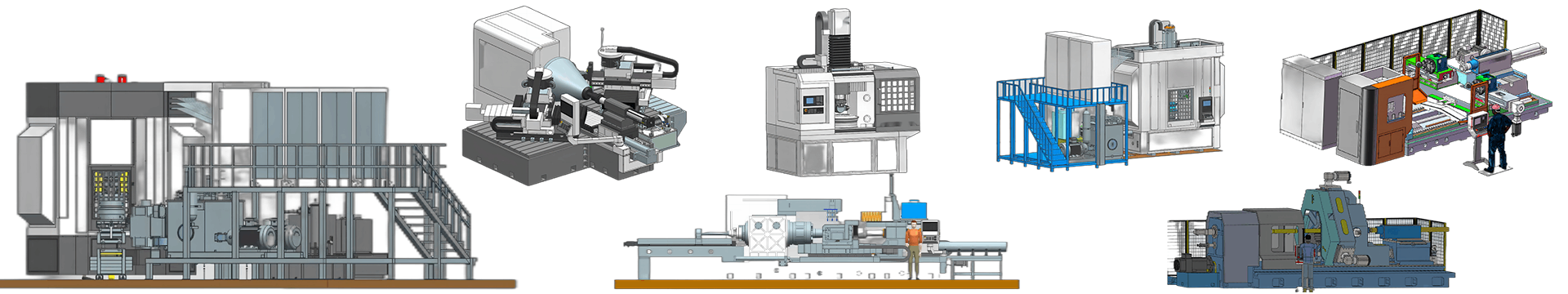

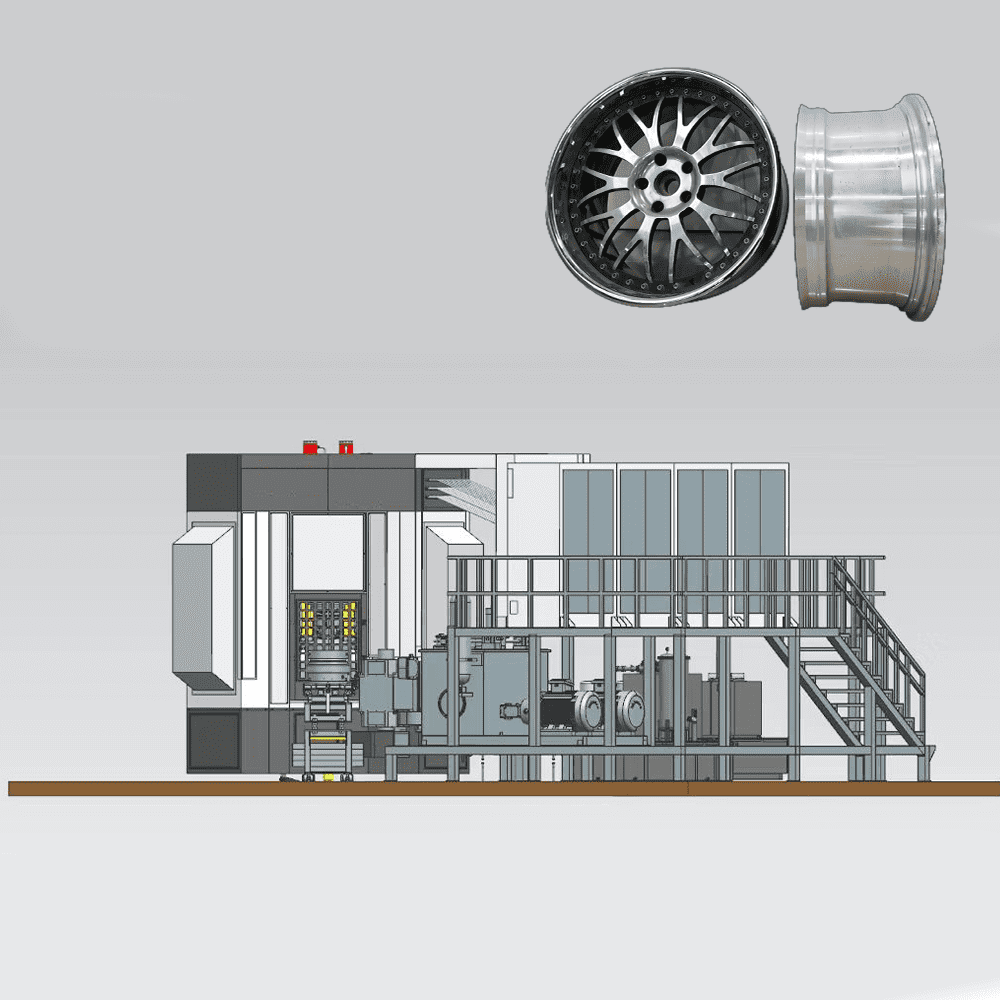

AC-1600SX Powerful Double Wheel CNC Spinning Machine

CNC Spinning Machine for Large Metal Spinning

|

Machine Name |

Powerful Double Wheel CNC Spinning Machine |

|

Model |

AC-1600SX |

|

Application Industry |

(can be modified) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours/7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

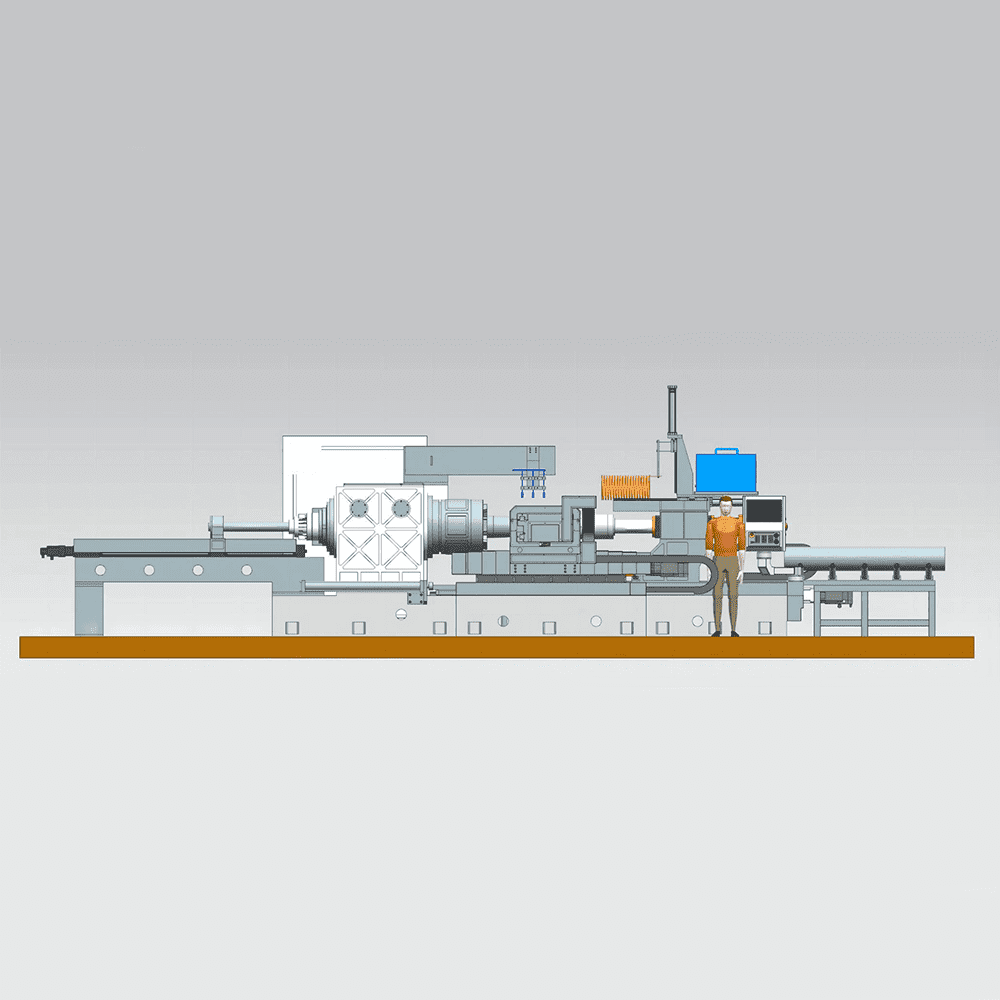

Altron’s AC-1600SX Powerful Double Wheel CNC Spinning Machine is a double roller metal spinning machine designed for large return workpieces! Due to its high precision and thrust, it is suitable for large diameter CNC spinning processing.

Customized high precision CNC spinning machine video

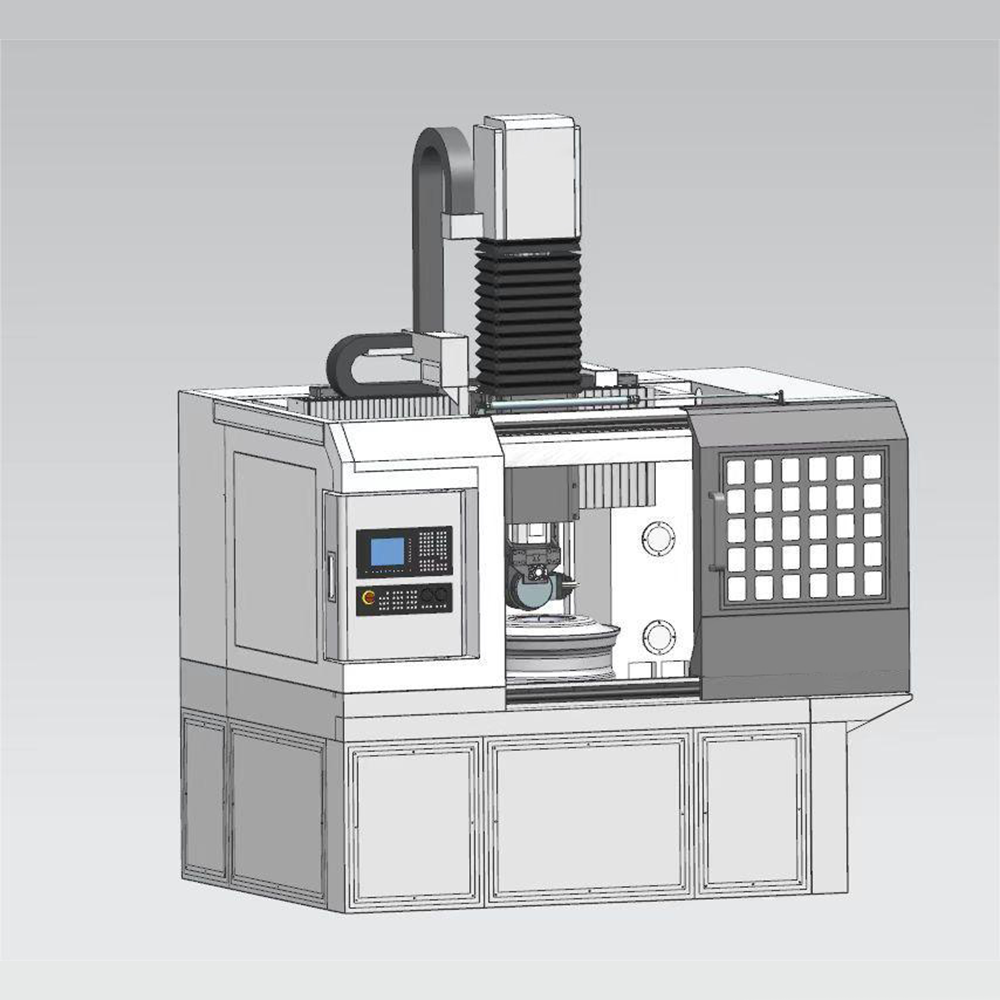

Main features of the machine tool

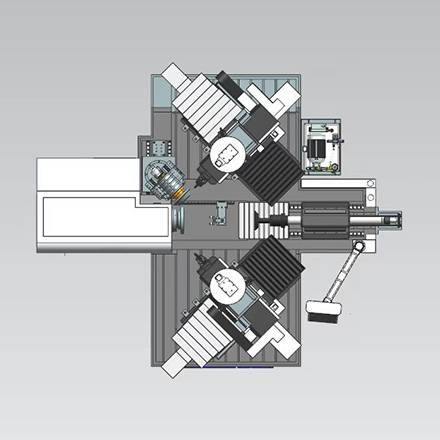

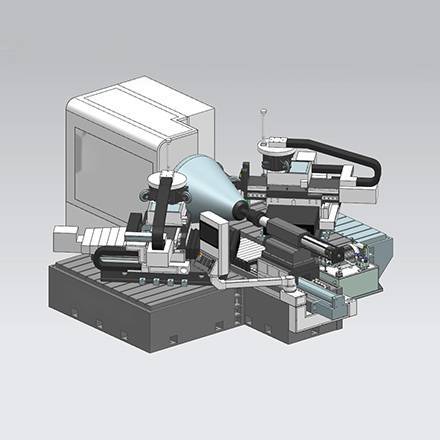

The AC-1600SX CNC powerful spinning center is a high-performance machine tool with a solid structure and superior design precision. It features a compact and optimized three-dimensional mechanical structure, combining high-strength castings for durability. The sliding table can be adjusted to optimize spinning strength, and the Siemens control system ensures powerful functionality and stability.

CNC Spinning Machine for Shape and Material

The CNC powerful spinning center offers a wide range of processing capabilities, including arc-shaped, conical, hemispherical, bullet-shaped, and complex curved surfaces with variable wall thickness. It can handle materials such as aluminum, copper, steel, and non-ferrous metals, enabling spinning, trimming, flanging, rolling, shaping, and even mandrel repairing. The full digital servo system allows for simple programming and offers strong applicability.

CNC Spinning Machine for Operating System

With the German Siemens SINUMERIK 828D multi-axis servo control system, the machine provides features like mandrel protection, automatic detection during startup, automatic lubrication, fault diagnosis, and overload protection. It enables axis linkage, linear and circular interpolations, and precise positioning through servo motor control and photoelectric encoder feedback.

In summary, the HYD-CNC1600SX CNC powerful spinning center offers a robust and efficient solution for a wide range of metal spinning applications. Its solid construction, precise design, and advanced control system make it a reliable and versatile machine tool in the industry.

| Project | Name | Unit | Parameter range |

| Processing capability | Range of machined hub diameters | English time | 14-26 |

| Spindle |

Servo spindle total power Spindle Revolution Spindle interface Tailstock spindle interface |

KW R/MIN DIN DIN |

150 50~800 variable speed DIN 55027 SIZE 15 DIN 55027 SIZE 8 |

| Roller |

Number of rotors Wheel diameter Maximum throat depth Roller mounting interface |

Of the project MM MM DIN |

2 380~400 60 DIN SIZE-6 |

| Spinning thrust |

The lateral thrust of the rotary wheel Wheel longitudinal thrust |

KN KN |

250 * 2 250 * 2 |

| The wheel moves |

Rotary wheel transverse machining speed Rotary wheel longitudinal machining movement speed The wheel advances the speed of movement laterally Rotary Wheel Longitudinal Fast Forward movement speed |

MM/MIN MM/MIN MM/MIN MM/MIN |

Max. 2000 * 2 Max. 2000 * 2 Max. 5000 * 2 Max. 5000 * 2 |

| Roller power |

Wheel lateral power Wheel longitudinal power |

Hydraulic Hydraulic |

Max. 20Mpa*2 Max. 20Mpa*2 |

| Roller stroke |

Wheel travel (X) Wheel’s longitudinal travel (Y) |

MM MM |

250 * 2 500 * 2 |

| Roller positioning |

Wheel lateral positioning accuracy Rotary wheel longitudinal positioning accuracy |

MM MM |

0.015 0.015 |

| Tailstock |

Seat travel Seat thrust |

MM KN |

700 100~250 |

| Hydraulic station |

Rated working pressure Hydraulic power |

MPa KW |

20 90 |

| Oil-cooled | Rated power | KW | 18.2 |

| Center distance | Center distance between top and bottom spindles | MM | 1460 |

| Return |

Spindle unload thrust Spindle discharge stroke |

KN MM |

50~200 100 |

| Equipment | Weight | Tons | 26 tons |

Product Details

| Parameter items | Unit | HYD-CNC1600SX double spin machine |

| Maximum disc diameter | Mm | 1600 |

| Distance between two centers (from spindle center to tail top center) | Mm | 1500 |

| Main motor | kW | 75 kw |

| X 1/x 2 Axis stroke | MM | 500 on one side |

| X 1/x 2 axis maximum thrust | Kn | 100 |

| X 1/x 2 axis maximum movement speed | Mm/min | 5000 |

| Z 1/z 2 Axis stroke | MM | 1000 |

| Maximum thrust on Z 1/z 2 axis | Kn | 100 |

| Maximum movement speed on z 1/z 2 axis | Mm/min | 5000 |

| Spindle speed | Rpm | 50-1200 CVT |

| Maximum tail thrust | Kn | 50 |

| Tail-top travel | Mm | 600 + 800 |

| Number of cutters (roller) | Pieces | 4 + 4/6 + 6 |

| Thickness of processed aluminum | Mm | 0.5-14 |

| Processing ordinary steel thickness | Mm | 0.5-8 |

| Stainless steel thickness | Mm | 0.5-6 |

| Spindle flange connection mode | GB | A2-11 |

| Machine weight | KG | 28000 |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The AC-CNC1600SX has significantly improved our production capabilities. The double wheel configuration has doubled our output without compromising quality. The machine’s CNC control system provides exceptional precision, and the servo hydraulic control ensures stable and accurate spinning. It has become an indispensable asset in our manufacturing process

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

As a wheel designer, I am impressed with the capabilities of the AC-CNC1600SX. Its double wheel configuration allows me to experiment with intricate designs and test prototypes efficiently. The CNC control system and programmable features offer unparalleled customization options, enabling me to achieve my desired wheel aesthetics and specifications. It’s a game-changer for our design team.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The AC-CNC1600SX has exceeded our expectations in terms of performance and reliability. Its CNC control system offers precise control, allowing us to consistently produce high-quality wheel hubs.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The machine’s fault alarm function has been a lifesaver, quickly alerting us to any issues and minimizing downtime. We highly recommend it to other wheel hub manufacturers.