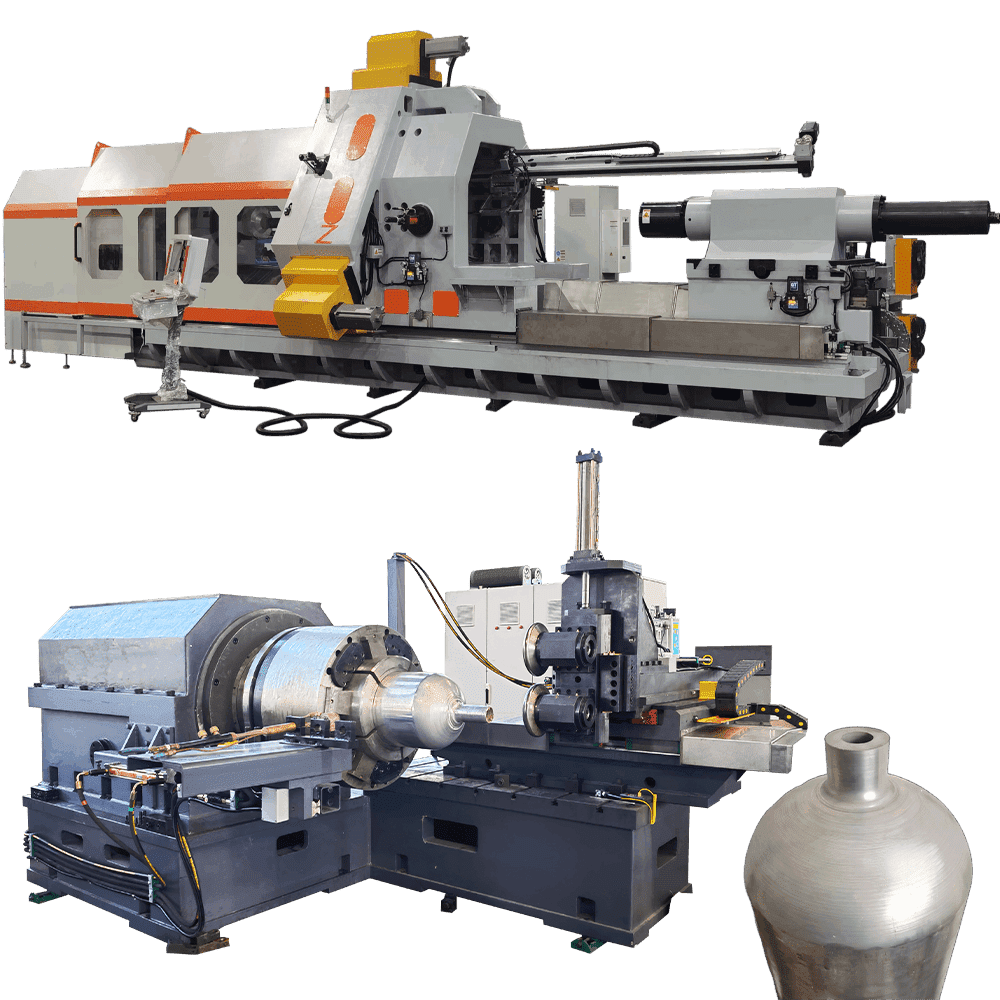

Multi-roller CNC Flow Forming Machines

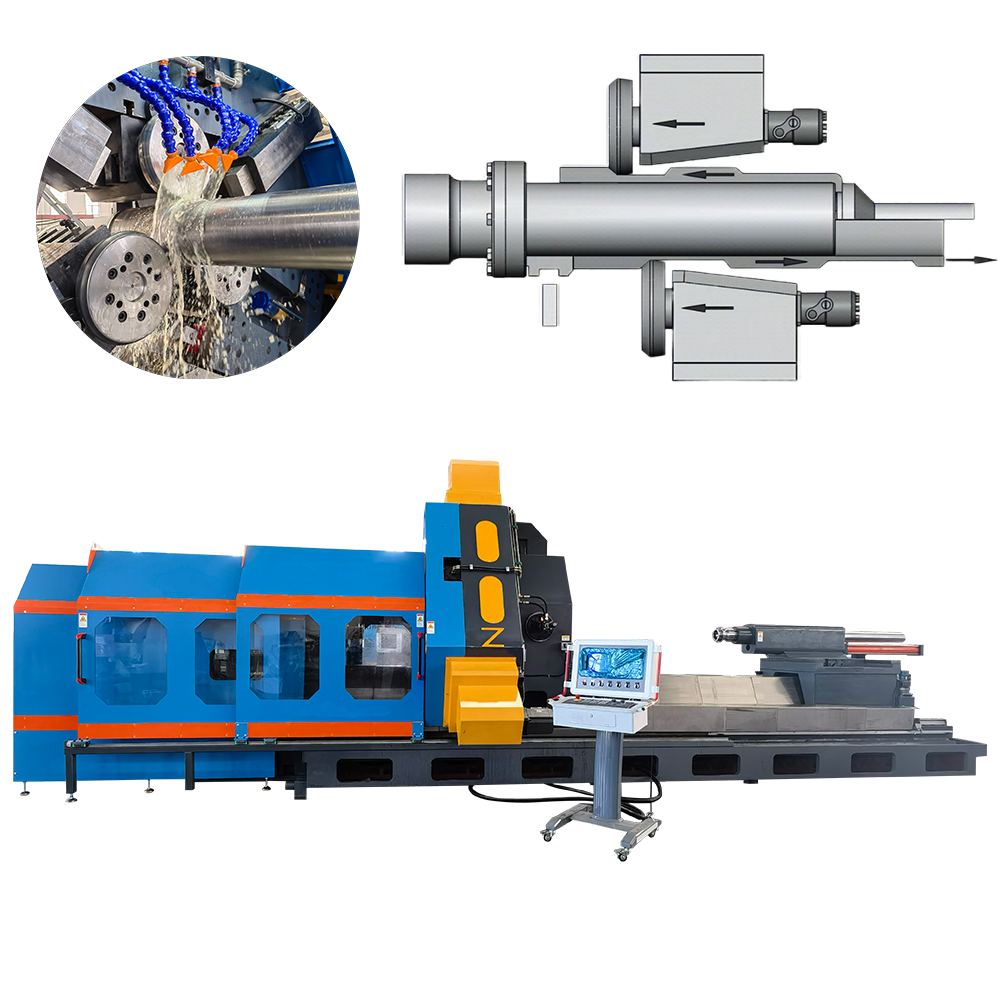

Altron's Multi-Roller CNC Flow Forming machine is equipped with an advanced Siemens CNC control system, an intuitive thrust data feedback interface and automatically programmable software-assisted functions that make it easier for operating engineers to operate the machine.

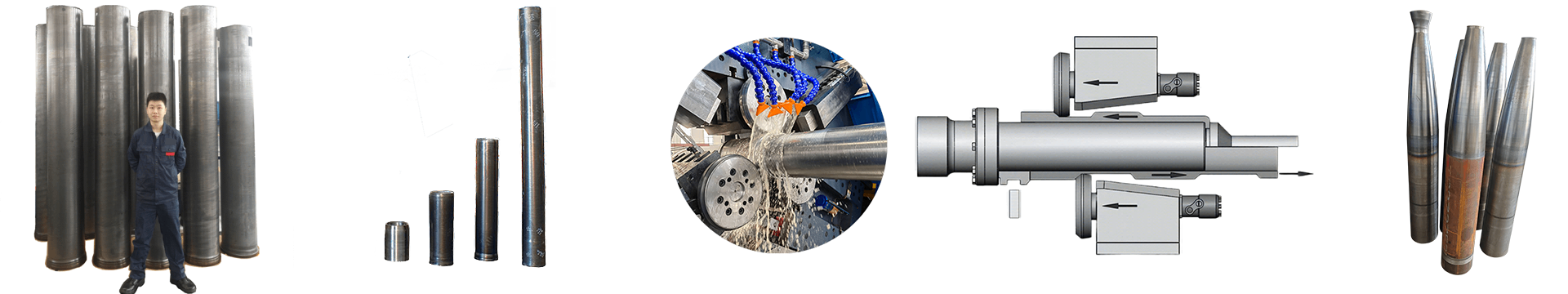

- Applications: military, spaceflight, aviation weapons, and other manufacturing industries

- Synchronizing spinning and stagger spinning

- Multi axes /multi-channel CNC control system

- Apple to carbon steel, alloy steel, stainless steel, nonferrous metal and other alloy material