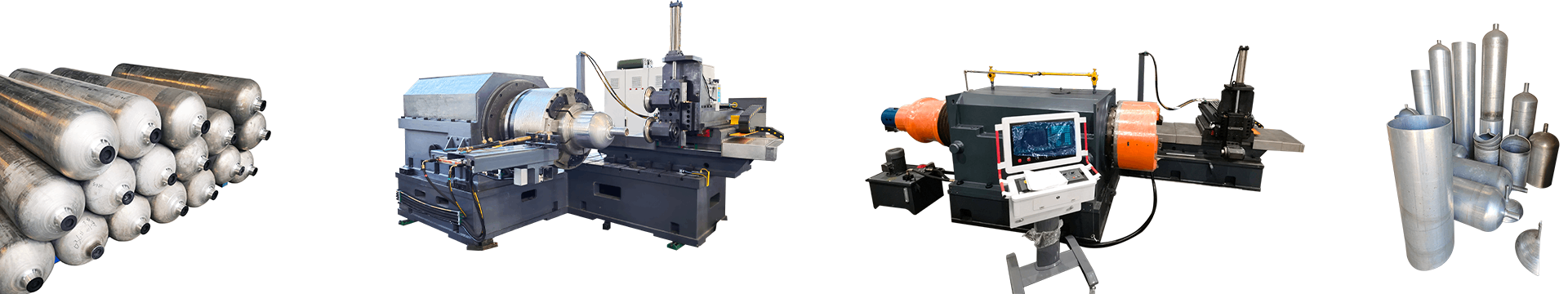

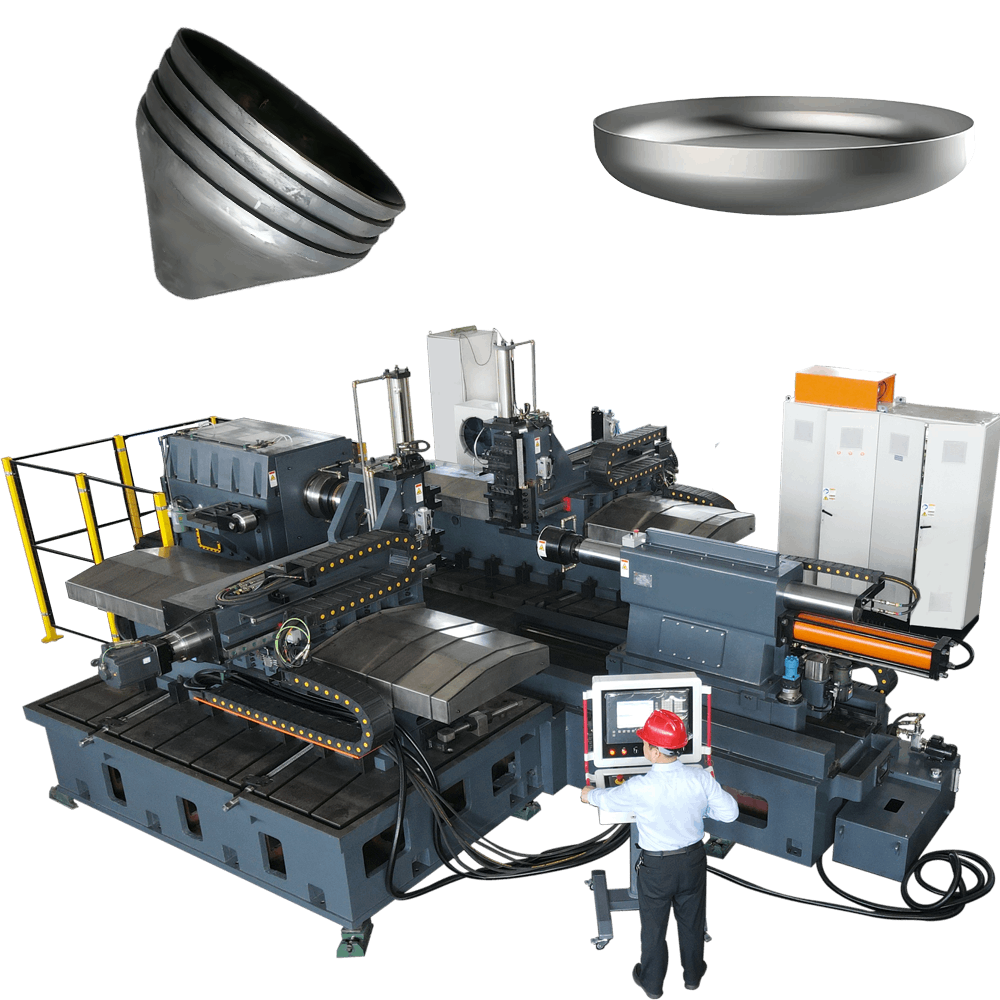

Necking CNC Spinning Machine AC-SK640

Necking Spinning Machine For Hydrogen cylinder

|

Machine Name |

Necking CNC Spinning Machine |

|

Model |

AC-SK640 |

|

Application Industry |

Hydrogen Cylinder, Gas Cylinders, Pressure Vessels,Cylindrical Tube Necking |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/Online Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

The Core Steps Of Metal Spinning Of Aluminum Alloy Hydrogen Cylinders

The inner liner of type III bottle is mostly made of aluminum alloy. At present, China generally uses flow forming + necking forming process.

Flow forming:

The strong spinning of aluminum tube is to put the shorter and thicker blank aluminum cylinder on the mold of the flow forming spinning machine and fix it. Rotate with the main axis of the machine tool, and use multiple sets of symmetrical spinning rollers to thin and stretch the blank to cause plastic deformation! The wall thickness of the blank is thinned, the inner diameter remains basically unchanged, and the axial extension is finally formed to meet the requirements of wall thickness and diameter size.

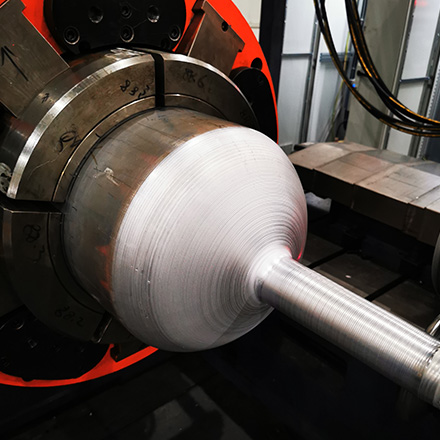

Necking Forming:

The necking of aluminum tube is to put the thinned and elongated cylinder into the necking spinning machine. The main axis is designed as a through-core main axis. The cylinder of the hydrogen cylinder is fixed and tightened on the main axis of the necking spinning machine. As the main axis rotates, the spinning roller radially extrude the tube. The motion trajectory is edited by the CNC system. After multiple spinning, the mouth of the hydrogen cylinder undergoes plastic deformation, the diameter gradually becomes smaller, and the mouth material will thicken with the proportion of the diameter change! Finally, the appropriate diameter of the mouth of the gas cylinder is formed.

Usually, different diameters need to be processed at both ends, and the finishing and threading are completed by the lathe process, and spinning usually only completes the forming work!

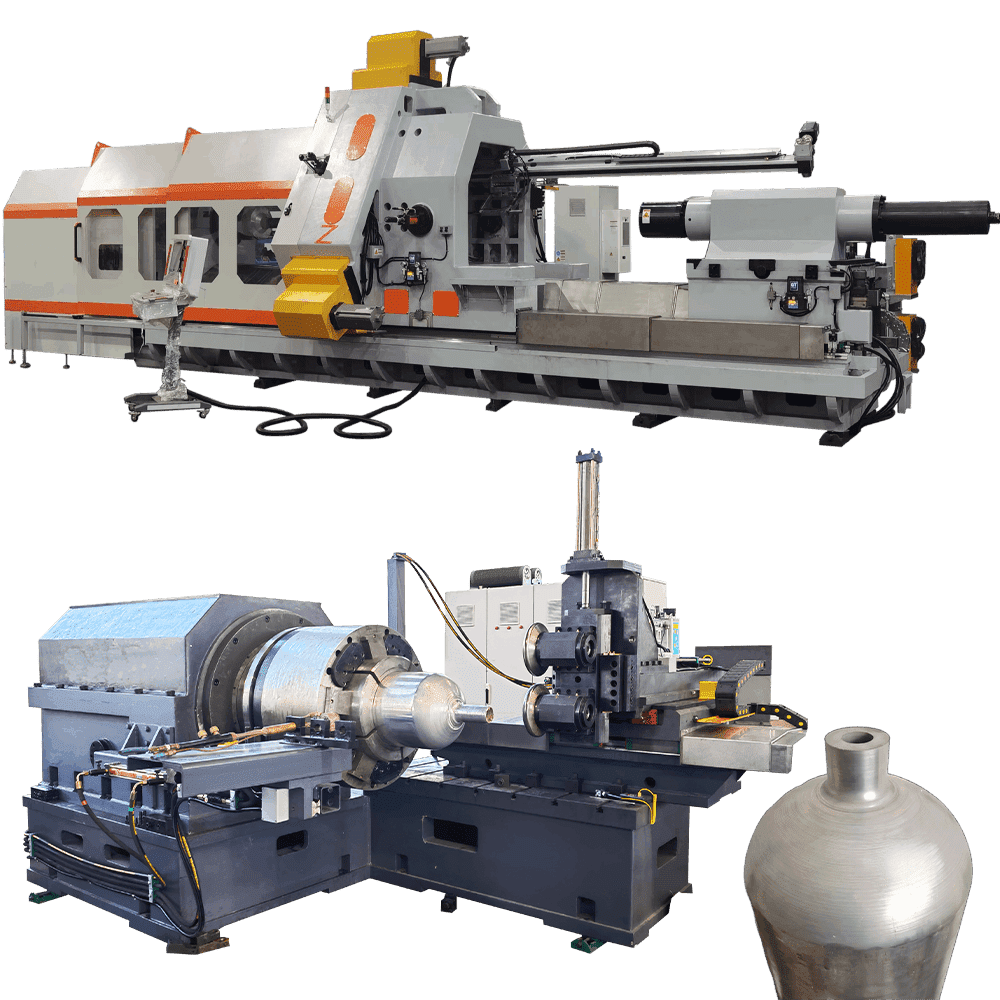

The Necking Process Of Hydrogen Cylinder

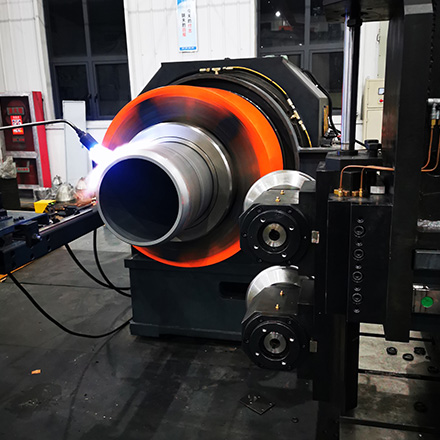

There are two types of neck shrinking processes for the inner liner of a hydrogen cylinder: normal temperature spinning and heated spinning!

Temperature control

- Heating range 250-350 degrees,

- Neck shrinking process uses heating intensity for compensation heating,

- Temperature detection instrument, usually infrared temperature measurement,

- The bottle mouth cannot be too hot, which affects the quality of the bottle body,

Spindle speed

Determined by the circumferential speed. The normal speed is 300 mm/min~450 mm/min. The larger the pipe diameter, the lower the spindle speed, while the smaller the pipe diameter, the higher the spindle speed. Taking the φ330 mm diameter aluminum alloy gas cylinder liner spindle neck as an example, the spindle speed is 350 rpm.

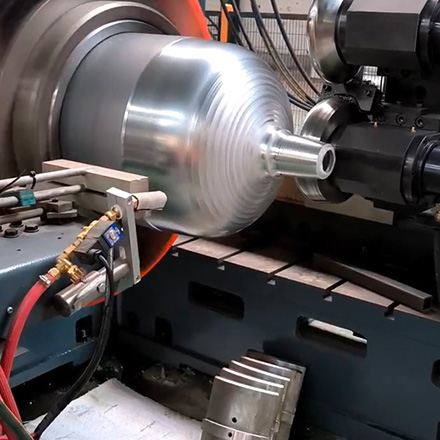

Axial spinning feed

The axial feed distance of each spinning pass is controlled at 3 mm to 10 mm. Taking the spinning of the inner shell of an aluminum alloy gas cylinder with a diameter of 330 mm as an example, the axial feed distance of each pass is selected to be 8mm.

Spinning roller swing angle

The rotary wheel swing angle is 0°~90°. The rotary wheel angle of the conventional neck shrinking CNC spinning machine is fixed, and the angle is changed by mechanical design!

Taking the spinning neck of the inner liner of the φ330 mm aluminum alloy gas cylinder as an example, the fixed angle is 80°; the data of the angle can be determined according to the specific shape of the gas cylinder of different shapes and sizes, and the shape and trajectory of the neck shrinkage determine the effect of the mouth forming.

Neck Forming Video Of Aluminum Alloy Hydrogen Cylinder Liner

The AC-SK series neck spinning machines are designed for large diameter hydrogen cylinders made of 6061 aluminum alloy.

Configuration

Standard Configuration

- SIEMENS CNC 840/828D

- SIEMENS Servo Motor & Drive

- Spindle SIEMENS Servo Motor & Driver

- Apex Servo Reducer

- Heavy Load Double Nut Servo Driven

- High Strength Casting Turret Seat

- High Strength Ductile Iron Sliding Table

- High Rigidity Heavy Spindle Structure

- Spinning Wheel with Hydraulic Motor

- Large Flow Circulation Cooling System

- Heavy Load Roller Guide

- Self-developed Spinning CAD

- CNC System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- The Grinding Head Device

- Customized Manufacture for Hot

- Auto Loading & Unloading Mechanism

- Double Wheel Feeding Slide

| Model No. |

Machining Dia. Range (mm) |

Forward Length (mm) |

Clamping System |

Clamping Force (KN) |

Feed Thrust (KN) |

| ACSK460 | ≤460 | 3000 | disc spring | 120 | 90 |

| ACSK640 | ≤640 | 3500 | disc spring | 150 | 110 |

| Model No. |

CNC System (KN) |

Power (KW) |

Heating Mode |

Operating Weight (KG) |

| ACSK460 | 828D | 110 | natural gas + oxygen | 23000 |

| ACSK640 | 828D | 135 | natural gas + oxygen | 26000 |

Machine Configuration Parameters

Technical indicators

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The ACSK Series machine has revolutionized our cylinder liner production. It delivers high productivity and exceptional product quality, exceeding our expectations

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

We are extremely satisfied with the ACSK Series equipment. Its smooth operation and reliable functionality have significantly improved our manufacturing process

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The ALTRON FB machine from the ACSK Series has transformed our cylinder liner production. The CNC dividing punching and excellent product compatibility have resulted in superior homogeneity and compatibility

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The integration of the SIEMENS control system and programming software V4.0 has made operating the ACSK Series machines effortless. It offers precise control and exceptional repeatability, enhancing our manufacturing efficiency