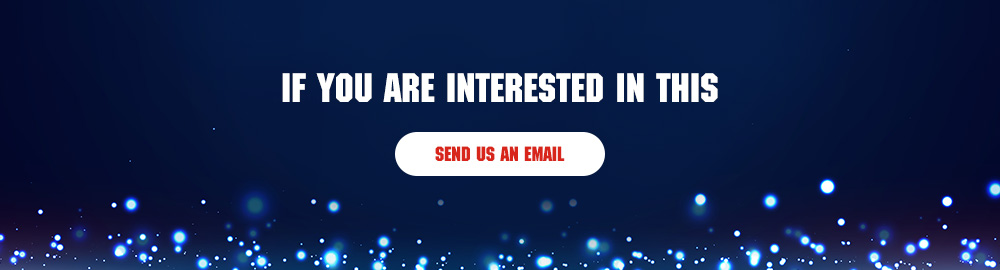

CNC Metal Spinning Machine -Double Roller AC-D1600

Spinning Machine For Metal Forming Solutions

|

Machine Name |

Double Roller CNC Spinning Machine |

|

Model |

AC-D1600(diameter max Ф1850;aluminum-Max 14mm; carbon steel-Max 8mm) |

|

Application Industry |

(Aerospace, military weapons, medical, furniture, lighting, construction, firefighting, musical instruments, handicrafts, auto parts, pressure vessels) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

CNC Metal Spinning Machine – Double Roller AC-D1600 has been installed and used in many aerospace engine manufacturers’ factories. This dual-drive spinning machine is very comprehensive in the field of large-diameter spinning. It only needs to reasonably increase the configuration and mechanism to easily process high-precision parts.

Among the workpieces processed by large-diameter CNC spinning, few products can be processed by standard machines, and generally need to add auxiliary mechanisms. The time and process of changing the process of large-diameter workpieces are very troublesome, and it is not easy to form industrialized mass production! We will try our best to reduce the process and save production costs.

Altron provides high-quality CNC spinning machine customization solutions for the market. The following will be detailed according to the customization of different structural components:

CNC Spinning Machine Working Video

Customized CNC spinning machine

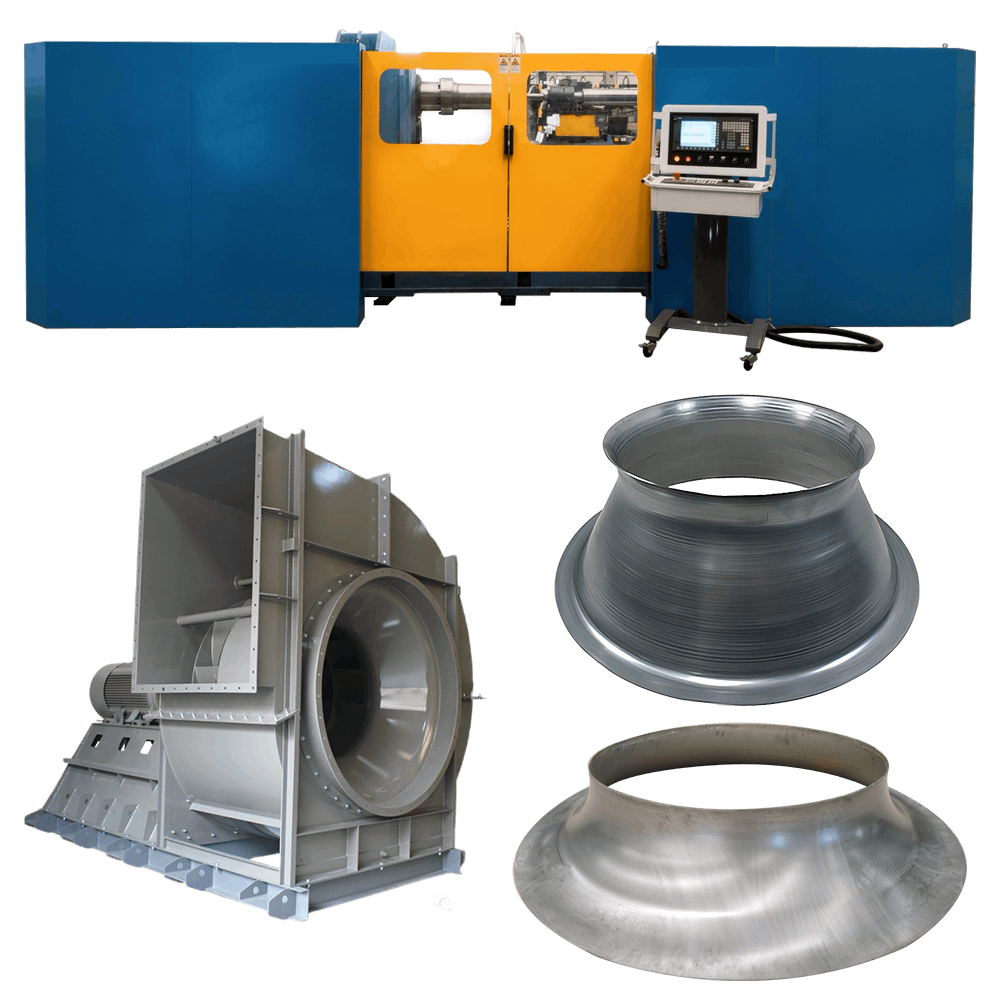

Altron’s CNC spinning machine mainly divided into two categories: electrical and mechanical. The mechanical part has 6 items: spindle box, frame, tailstock, slide, support mechanism, turret; the electrical part has 3 parts: operating system, cooling system, heating system.

Detailed description of the customization of each mechanical part…

Mechanical part of CNC spinning machine:

Spindle box:

The spindle structure of the CNC spinning machine is the main core part of the CNC spinning machine. It not only needs to drive the bulky metal mold, although the spinning mold has been lightened, but due to the diameter factor, almost all molds over 1500mm weigh more than 5-6TD; it also needs to bear the deformation support force of the material; the thrust of the drive shaft; the thrust of the tailstock hydraulic cylinder;

There are 9 conventional spindles and 4 heavy-duty special spindles at present; they have all been tested and improved, and have been tested by the market! Excellent performance in all aspects!

Frame:

The design of CNC spinning frame is strictly in accordance with the machine tool design standards. The overall casting structure has reasonable rigidity, strength and seismic resistance. The aging treatment of the frame is very strict, otherwise there will be serious deformation in the subsequent processing process.

The processing technology must go through: multiple roughing, semi-finishing, finishing, and the intermediate process needs to go through aging treatment, annealing to remove stress, vibration to eliminate stress and other processes;

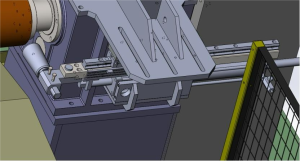

The frame is designed with T-slots to facilitate the movement of the slide on the machine tool. The slide movement auxiliary mechanism can be added to allow the spinning slide to easily change the angle and position.

At present, our company has 600-3800mm spinning machine models of frames to choose from;Single roller, Double reoller ,Shrink roller spinning mechanism, a total of more than 30 types of the metal spinning machine Frame!

Tailstock

The function of the tailstock is mainly determined by the customer’s product:

- For products with longer diameters, it is not necessary to design the frame very long, and a side-shifted tail top structure can be used.

- Hemispherical products can use a double tail top structure. When the front half is spun, a small diameter tail top is used. After the front section of the spinning is completed, the large tail top is ejected to increase the contact surface of the tailstock to prevent the spinning workpiece from shifting.

- When spinning thin-walled parts in a necking barrel, a servo tailstock is required. Its main function is to follow the movement of the spinning rollers, improve efficiency, and prevent wrinkles during the metal spinning process.

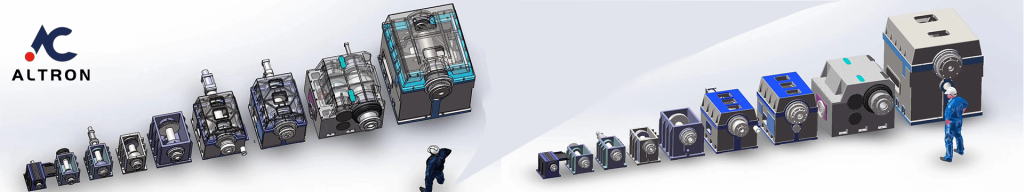

Slide

The slide is the core of the spinning machine. The thrust and precision diameter it generates determine the precision and quality of the product; it is mainly divided into two categories: light spinning and heavy spinning.

|

|

- Light spinning: mainly for thinner materials, the feed speed needs to be fast, and the speed ratio of the reducer connected to the motor cannot be too large;

- Heavy-duty spinning: On the contrary, facing high-hardness and thick metal sheets, a considerable thrust is required, the speed ratio of the reducer is high, and the feed speed is relatively slow. This requires a trade-off, large thrust, slow feed, ordinary spinning, small thrust, fast feed!

Support mechanism

Determine whether it is light or heavy load according to the thickness of the product, and increase the reserve by 40% according to the actual material yield strength to ensure the stability of mechanical properties:

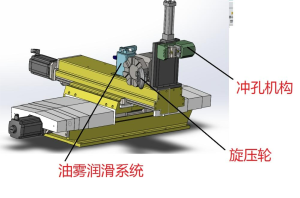

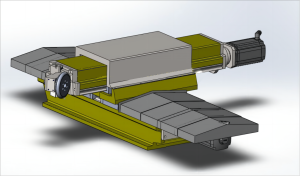

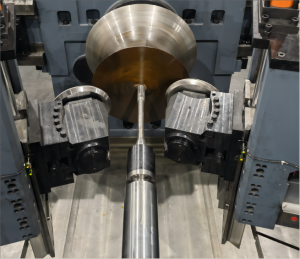

Heavy-duty CNC spinning machine support mechanism

|

|

Light-duty CNC spinning machine support mechanism

|

|

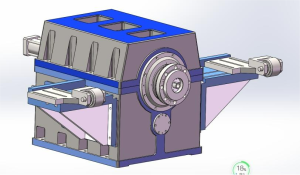

Turret

Altron generally purchases external turrets for light spinning machines, which are divided into 6-station and 8-station;

For heavy-duty spinning machines, we will use self-developed turrets: 2+2 symmetrical metal spinning layout; 1+4 main spinning and auxiliary metal spinning layout;

|

|

Electrical part of CNC spinning machine:

Our conventional CNC spinning machine is equipped with 828D; light CNC spinning machine uses 808D; special metal spinning machine, or machine over 2500mm will choose 840D;

It will be more based on the actual needs of the system software! When large-scale spinning machine processing needs to see data feedback, the function of 840D will be more comprehensive.

CNC spinning machine cooling system:

Altron will add cooling equipment according to actual needs. According to the use environment, use process, and temperature control, equipment with different functions will be installed in different areas:

- Air conditioning cooling in the electrical cabinet,

- Cooling machine in the spindle box,

- Lubrication cooling of the spinning roller,

- Mechanical water cooling system with heating device,

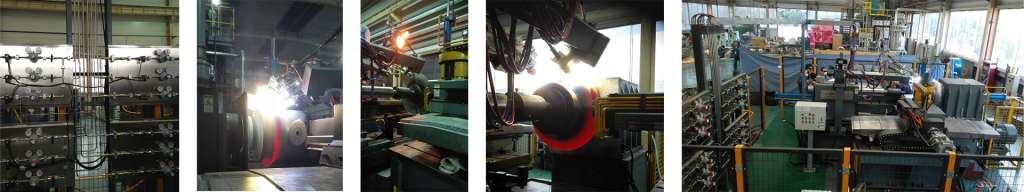

Heating system of CNC spinning machine:

When the metal is spun on thicker materials with higher hardness, an automatic heating system needs to be added, commonly known as hot metal spinning:

The price deviation of domestic and German gun nozzles, valves, etc. is large, depending on the scope and requirements of stable control of the metal spinning heating process;

Altron’s Factory Video

Altron provides customized CNC Metal Spinning Machine. All spin machines with diameters less 3800mm have successful cases & customer factories for visits .

please contact me and Joby engineers will give you a detailed plan.

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- Two Turrets Tool Setting Simultaneously

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| ACD-600 | 600 | 260 | 1100 | 40 | 20 | 18.5 | 50-1000 | 6 / 4 / 3 |

| ACD-800 | 1300 | 400 | 1600 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| ACD-1200 | 1650 | 500 | 800 | 80 | 50 | 37 | 30-500 | 10 / 6 / 4.5 |

| ACD-1600 | 1800 | 600 | 1000 | 120 | 70 | 45 | 30-450 | 14 / 8 / 5.5 |

| ACD-2000 | 2000 | 750 | 1250 | 140 | 100 | 75 | 30-400 | 20 / 12 / 7 |

| ACD-2500 | 2500 | 850 | 2050 | 200 | 140 | 132 | 10-300 | 30 / 20 / 15 |

| ACD-3500 | 3500 | 950 | 2550 | 300 | 140 / 200 | 200 | 10-300 | 40 / 25 / 20 |

Machine Configuration Parameters

Technical Specification

Ball screw rod

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The Double Wheel CNC Spinning Machine has revolutionized our spinning operations. The accuracy and surface quality it delivers are truly outstanding. We can handle large blanks up to 2500mm in diameter with ease, and the results are always precise.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The machine’s shock protection system ensures smooth and stable operation, even during demanding tasks. It has greatly enhanced our productivity and allowed us to expand our capabilities. We highly recommend the double wheel spinning machine.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The machine’s versatility allows us to work with long and thin goods as well as cone-shaped products, expanding our product range. The combination of the SIEMENS control system and the user-friendly programming software makes operation seamless. It has been a game-changer for our spinning operations

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We are extremely satisfied with the performance of the Double Wheel CNC Spinning Machine. It has exceeded our expectations in terms of accuracy and surface finish. The symmetrical distribution of spinning force and pressure to the spindle provides excellent shock protection, ensuring consistent and reliable spinning results.