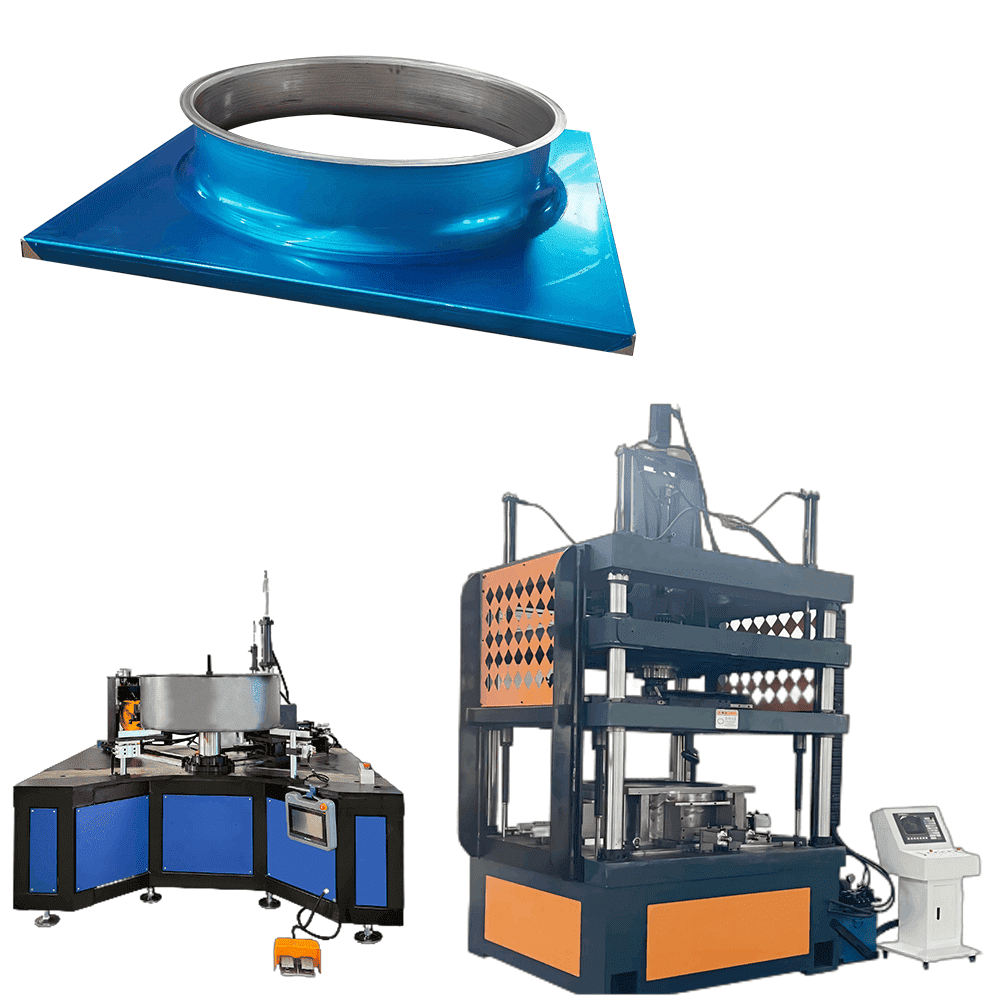

CNC Metal Spinning Machine for Funnel-Stainless Steel-Double Roller AC-D600

Metal Spinning for Funnel-Stainless Steel

|

Machine Name |

Double Roller CNC Spinning Machine |

|

Model |

AC-D600(diameter max Ф600;aluminum-Max 6mm; carbon steel-Max 3.0mm) |

|

Application Industry |

(Aerospace, Aviation Weapons, Medical, Furniture, Lighting, Building, Fire, Musical Instruments, Crafts, Automotive Parts, Pressure Vessel,) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

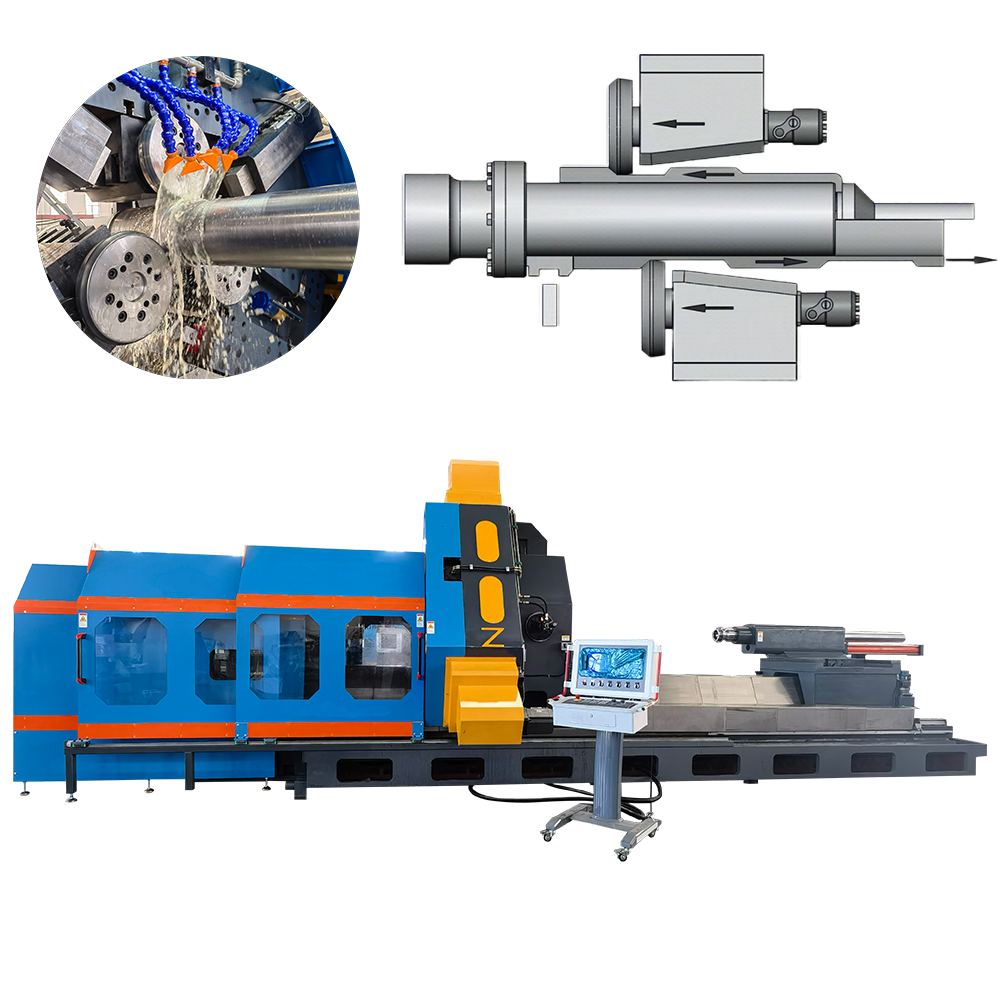

Altron’s Double Roller CNC Metal Spinning Equipment can spin aluminum alloy, carbon steel, stainless steel and other high-strength metal materials, and can spin round materials with a diameter of 620mm. The product length is 600mm Max. It is widely used in hardware, lamps, musical instruments, automobiles, fans, military and other fields, especially metal spinning of slender tubular parts, necking, and variable diameter spinning has great advantages.

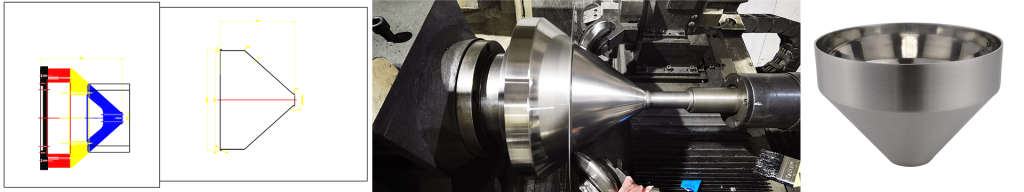

For example, stainless steel funnel metal spinning is composed of a taper from a small diameter to a large diameter and a straight barrel shape of a cylindrical surface.

The CNC system uses Siemens 808D, and 820D is optional. To improve the efficiency of metal spinning production, Altron has developed metal spinning software, which can realize the automatic production of G code programs from graphics, including the spindle speed S, feed speed F, fast positioning speed G0 F, etc. The production of this spinning machine is stable and reliable!

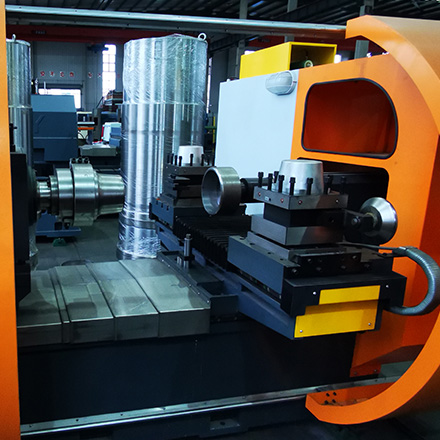

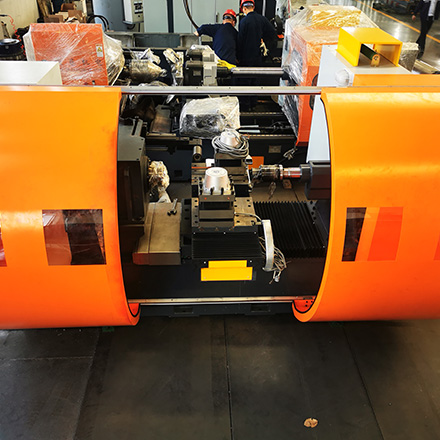

CNC Spinning Machine AC-D600 Structure Introduction:

Spindle unit:

The spindle structure of CNC spinning machine is designed to be heavy-duty for the spinning process; it is equipped with a 7.5kw motor, and the inverter is controlled by the Siemens system. The spindle box frame is integrally cast to ensure strength!

Frame:

HT250 has an integral casting body, which has good vibration resistance and stability, ensuring the stability of metal spinning.

Tailstock:

Integrally cast, the movement is carried out by two-stage hydraulic cylinders, with a stroke of 400mm+700mm. To adapt to the weight of different top plates, the tailstock is designed with a central fine-tuning mechanism, which can easily adjust the coaxiality with the main shaft.

Spinning work slide:

The horizontal slide and main connecting parts are made of QT450 castings; strong rigidity and good vibration resistance.

The X-axis adopts a fixed slider reverse mounting structure to increase the table utilization rate and effectively increase the product size. The ball screw and linear slide rail are both heavy-duty products to improve the rigidity and life of the equipment.

Spinning tool turret:

The left and right slides are equipped with electric CNC heavy-duty turrets, and 12 different spinning wheels or tools can be installed according to needs.

X, Z axis power motor:

The power adopts Siemens Germany 1FL6 series servo motor and V70 drive system, with stable and reliable performance. Motor power: 15NM 2500 RPM

Metal Spinning Equipment for Stainless Steel Funnel

Stainless steel funnel is a very common metal accessory. Food, medical, powder, medicine, and other canning industries all need to use hoppers. Stainless steel hoppers are generally used in industries with higher requirements, such as the canning environment of medicines. They must be made of 316 food-grade stainless steel!

Products with loophole shapes are very suitable for metal spinning, and are suitable for two metal forming processes: shear spinning and pull spinning.

Key points of metal spinning of stainless steel funnel:

Mold design:

The mold core must be made of CR12 or higher hardness materials; especially in the case of spinning stainless steel, the mold must undergo a heat treatment process, and the hardness must reach 58-62° to ensure stable production!

Selection of spinning tool wheels:

- For the conical part, a spinning tool wheel with a smaller R should be selected to ensure the fit between the material and the mold core;

- For the straight barrel part, the pull-up spinning process is suitable, and a spinning tool wheel with a larger R should be used to ensure uniform thinning of the material and prevent the material from thinning too quickly and cracking.

Spinning process:

- Taper shear spinning must fit the material tightly to the model. The reference data can be obtained through the shear spinning calculation formula to set the gap between the spinning roller and the mold. The hardness of stainless steel is relatively high, which will be about 0.2-0.3mm smaller than the theoretical calculated value.

- If the front cone does not fit the mold, the rear straight barrel part cannot be spun, and the support of the bottom is very important.

- If you encounter a higher barrel shape, you need to use the hot metal spinning process to increase the ductility coefficient of stainless steel and reduce the hardness! Improve production stability.

Solutions to cracks in the metal spinning process:

- Check the synchronization of the spinning rollers;

- Check the runout of the spinning rollers and whether there are scratches on the surface;

- Check the runout of the mold and whether there are other impurities attached to the mold surface;

- Measure the gap between the spinning roller and the mold;

- Slightly polish the edge gap of the laser-cut disc;

- Whether the raw materials are of the same brand and manufacturer;

- Cool the spinning oil to prevent the mold from heating up too much, causing the mold to expand and the gap to become smaller! Then

- the spinning tool will compensate the appropriate data in the positive direction!

Stainless steel funnel hot spinning video

If you plan to produce stainless steel funnels or encounter unsolvable technical problems when spinning stainless steel, please contact me and Joby engineers will give you a detailed plan.

Altron’s Factory Video

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- Two Turrets Tool Setting Simultaneously

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| ACD-600 | 600 | 260 | 1100 | 40 | 20 | 18.5 | 50-1000 | 6 / 4 / 3 |

| ACD-800 | 1300 | 400 | 1600 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| ACD-1200 | 1650 | 500 | 800 | 80 | 50 | 37 | 30-500 | 10 / 6 / 4.5 |

| ACD-1600 | 1800 | 600 | 1000 | 120 | 70 | 45 | 30-450 | 14 / 8 / 5.5 |

| ACD-2000 | 2000 | 750 | 1250 | 140 | 100 | 75 | 30-400 | 14 / 10 / 7 |

| ACD-2500 | 2500 | 850 | 2050 | 200 | 140 | 132 | 10-300 | 30 / 20 / 15 |

| ACD-3500 | 3500 | 950 | 2550 | 300 | 140 / 200 | 200 | 10-300 | 40 / 25 / 20 |

Machine Configuration Parameters

Technical index

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The Double Wheel CNC Spinning Machine has revolutionized our spinning operations. The accuracy and surface quality it delivers are truly outstanding. We can handle large blanks up to 2500mm in diameter with ease, and the results are always precise.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

We are extremely satisfied with the performance of the Double Wheel CNC Spinning Machine. It has exceeded our expectations in terms of accuracy and surface finish. The symmetrical distribution of spinning force and pressure to the spindle provides excellent shock protection, ensuring consistent and reliable spinning results.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The machine’s versatility allows us to work with long and thin goods as well as cone-shaped products, expanding our product range. The combination of the SIEMENS control system and the user-friendly programming software makes operation seamless. It has been a game-changer for our spinning operations

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The machine has been used for 3 months. The effect is very good, and I am satisfied with it. I will buy another one soon.