Automatic Damper Frame Forming Production Line

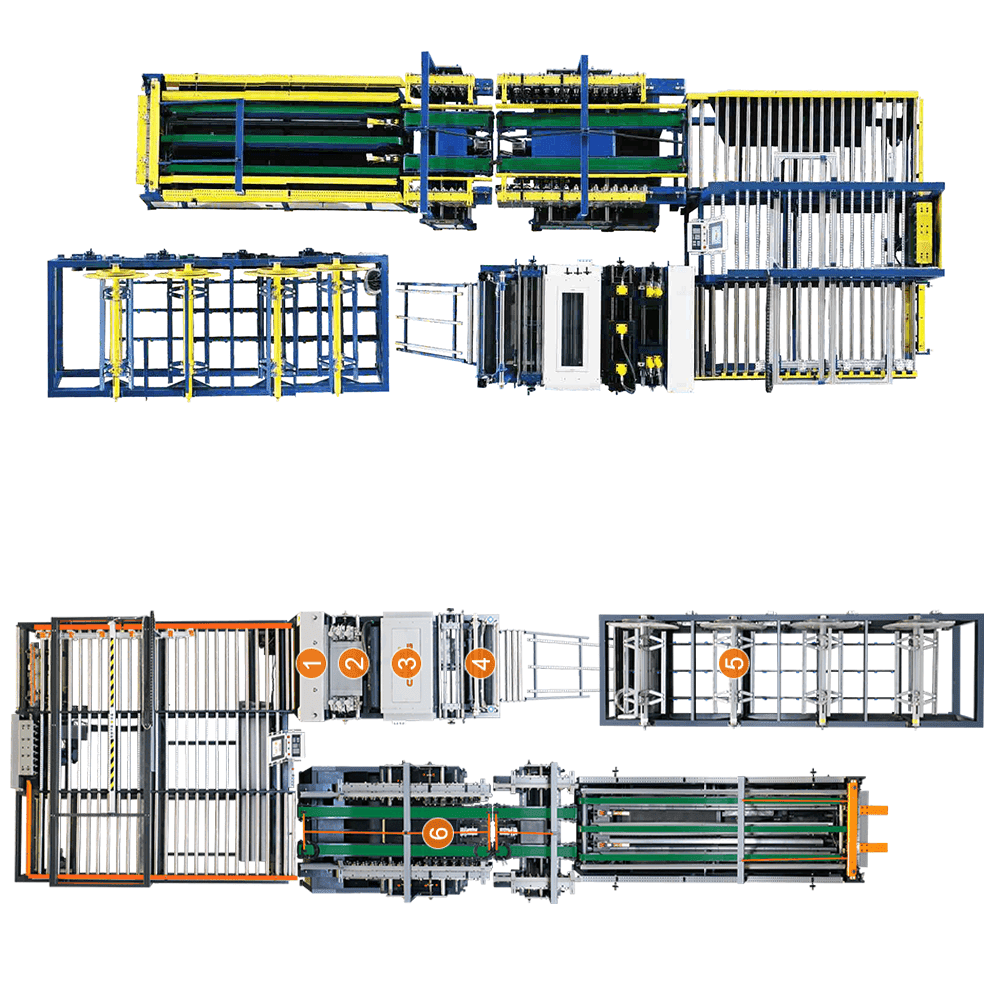

Automatic Damper Frame Forming Production Line For Damper

|

Machine Name |

Automatic Damper Frame Forming Production Line |

|

Model |

AC FF |

Relevant Files

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project

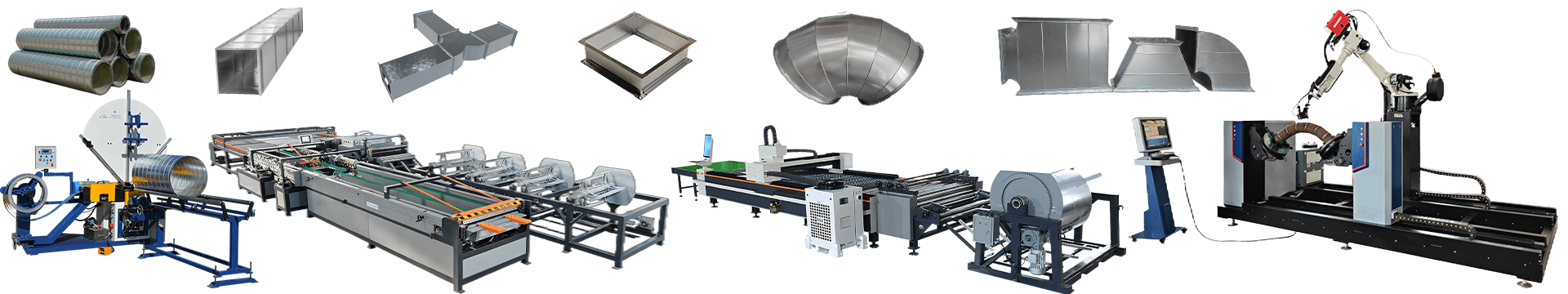

Air Duct A-Z Project:

1 Rectangular duct forming line

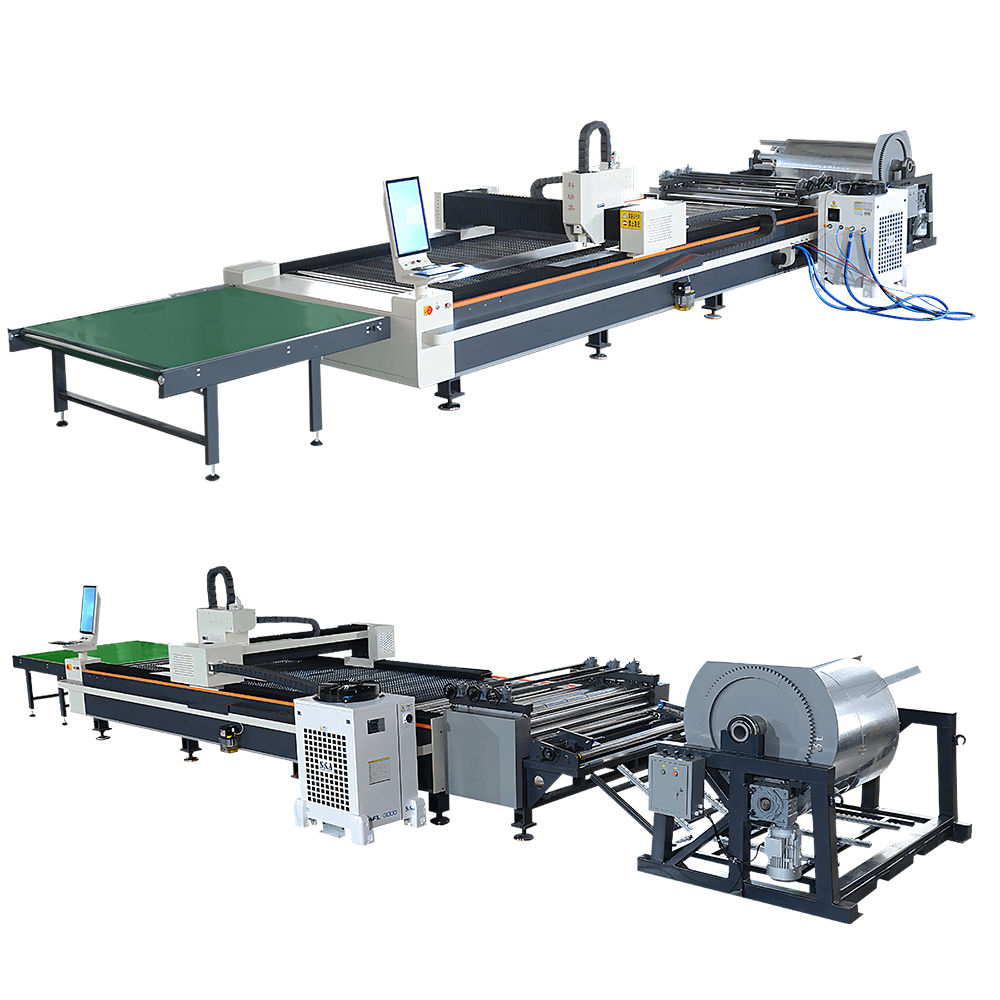

2 Continuous laser cutting production line

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Features of Automatic Damper Frame Forming Production Line

It mainly completes the processing of fire damper, pressure regulating damper, damper outer frame and the blanking of smoke exhaust damper. The production line can automatically complete uncoiling, leveling, notching, punching, shearing, flange forming (including TDF flange 35 and angle iron flange 30, 40, 50), square folding and forming automatically.

Advantages of Automatic Damper Frame Forming Production Line

- Fully functional, can complete all the holes and cutting corners on the housing of volume damper, change the traditional processing methods by punch machine manually, improve production efficiency, ensure the products consistency.

- Reduce labor, just need 2 workers to operate the machine.

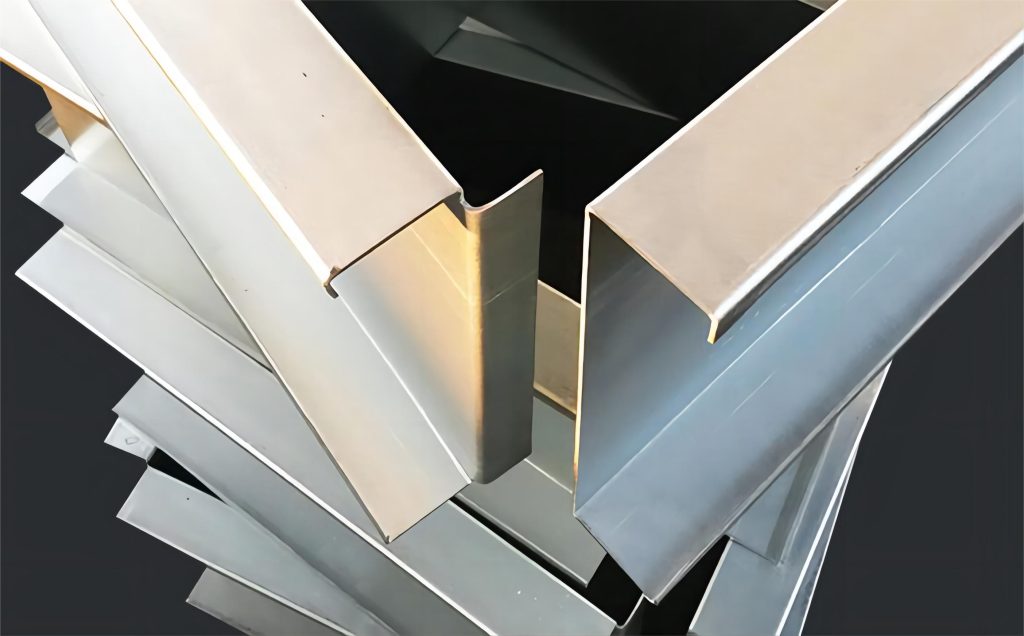

- You can also input various specifications, not only can make the “口” type, you can also complete a variety of shapes, such as the “L”type and monolithic type etc according to the actual situation of customers.

- The same machine can complete the volume damper forming for TDF flange and angle steel flange, fully realized that one machine for multi functions.

The Forming Effect Of The Damper

Video of Automatic Damper Frame Forming Production Line

| Model No. | Thickness (mm) |

Max. Sheet Width (mm) |

Max. Feeding Speed (m/min) |

Power (KW) |

Dimension (L×W×H) |

Max. Coil Gross Weight (KG) |

| AC FF | 1.5-2.0 | 450 | 8 | 31 | 22000×1600×1500 | 3000 |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Damper Frame Forming Production Line in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our forming process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise forming results consistently. We highly recommend this machine to anyone in need of reliable and high-quality Forming

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Damper Frame Forming Production Line has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we forme materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise forming results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.