CNC Metal Spinning Machine -Single Roller AC1600

Metal Spinning For Roof Fans & Indusrital Fans

|

Machine Name |

Single Wheel CNC Metal Spinning Machine |

|

Model |

AC1600:(diameter max Ф1670;aluminum-Max 10mm; carbon steel-Max 6mm) |

|

Application Industry |

(Aerospace, Aviation Weapons, Medical, Furniture, Lighting, Building, Fire, Musical Instruments, Automotive Parts, Pressure Vessel, Ventilation & Fans) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

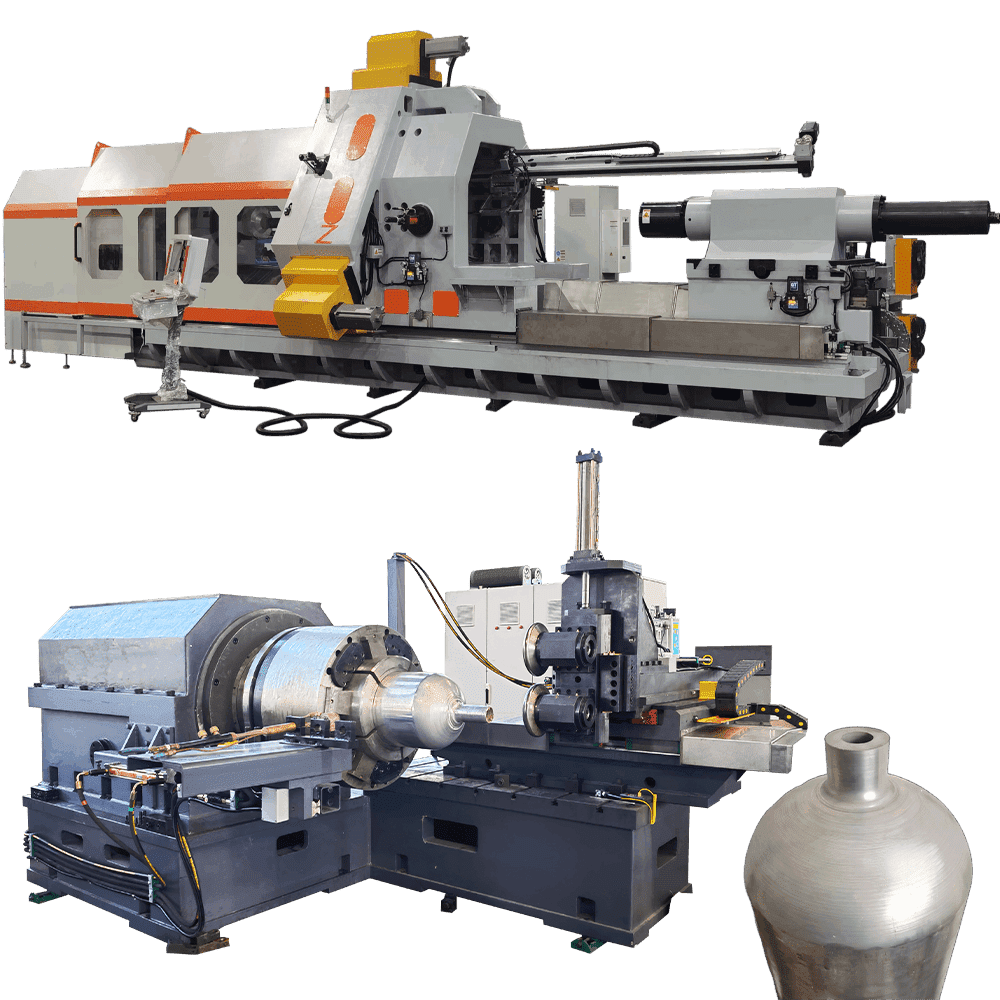

Single Roller CNC Metal Spinning Machine-AC1600 Introduction:

Single-Roller CNC Metal Spinning Machine-AC1600 was developed in 2009, and the first machine was sold to a fan manufacturer in Malaysia. After more than ten years of production and operation, the machine is currently in good condition, and only the lubricating bearings and other accessories have been replaced, which are lubricating wear parts! This is a CNC spinning machine with historical significance in spinning!

The machine has undergone multiple generations of upgrades and its performance is even better! AC1600 is widely purchased by industrial fan manufacturers; since the large batch of fan accessories are generally in the range of 1200mm diameter, that is, the disc material is about 1500mm diameter, this machine is very suitable for the production needs of actual fan factories:

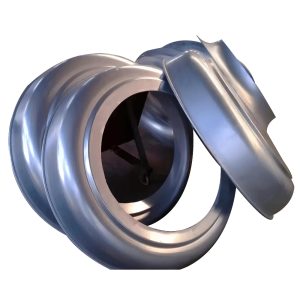

- Centrifugal Fans: Air Inlet Funnel, Impeller Shrouds;

- Axial Fan: Air Collectors, Guide Cover, Impeller Hub, Bell Mouth;

- Mixed Flow Fan: Impeller Hub, Impeller Shroud;

- Roof Fan: Rain Cap, Motor Cover, Roof Fans Shroud, Curb Cap,

And many more specially customized industrial fans, industrial air conditioning and ventilation accessories; the number of customized industrial fans is very small, and the use of CNC spinning industry can save a lot of mold costs and time costs.

Working Video Of Spinning Machine

Spinning Technology Solutions For The Roof Fnas

At present, Altron’s CNC spinning machines and other metal forming equipment are used by more than 300 industrial fan manufacturers. We have absolute experience in metal spinning and metal flanging for industrial fans!

Whether it is a customized CNC machine or a standard metal CNC spinning machine, we will use actual manufacturing experience to help customers evaluate the feasibility and success rate of the plan! We can help you complete more risk elimination before sales to ensure the smooth progress of your project!

This is an advantage that other CNC metal spinning machine manufacturers do not have! When you propose a new process manufacturing, we will test and verify it according to the actual situation!

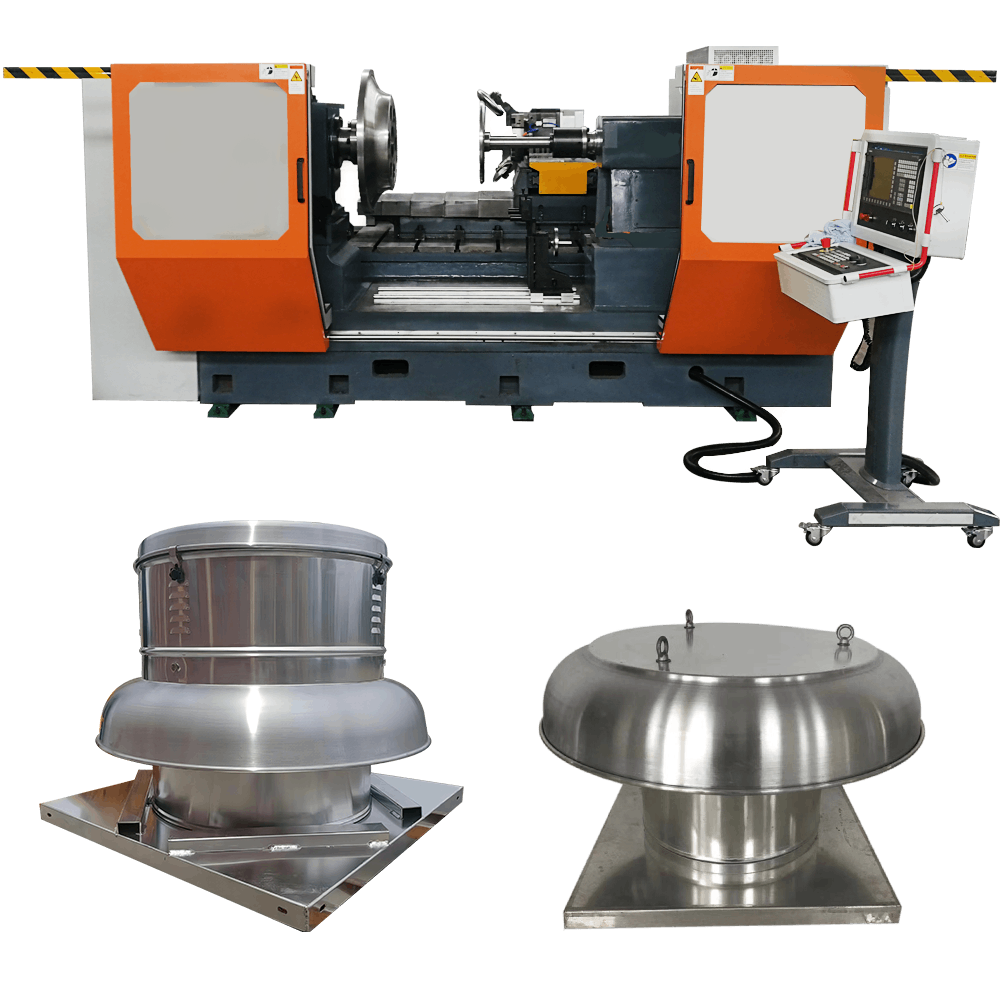

CNC Spinning For Roof Fan Manufacturing:

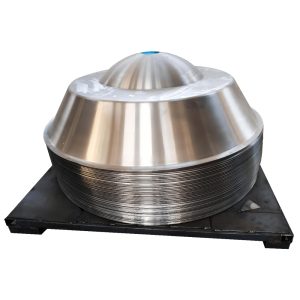

Most of the main materials of roof fans are aluminum or aluminum alloys. Most of the application environments are at high altitudes, so weight and strength are very critical!

The spinning performance of metal aluminum is very stable. The tensile strength of aluminum is low, only about 230 MPa, but many application scenarios require strong working conditions; for example, aluminum alloy impellers need to run continuously at high speed. In this case, we should spin aluminum alloy materials during manufacturing and design. Many domestic industrial fans will use 3003 series or 5052 aluminum alloy materials.

For the shrouds of roof fans, 1060 or 1070 aluminum, commonly known as pure aluminum, is generally used. This accessory mainly guides the wind and is a non-moving part. The normal wall thickness is not less than 0.9mm, and the diameter of the roof fan data is about 1200!

Because aluminum roof fans are widely used in the United States, North America, Europe and other regions, the quality requirements for appearance are also high. During the spinning process, the factory generally removes the spinning oil manually before it is completed, and then performs manual surface polishing! (Aluminum has a low melting point. Long-term friction will cause aluminum powder to oxidize on the surface of the workpiece. At this time, adding a little diesel can achieve a very good finish effect.)

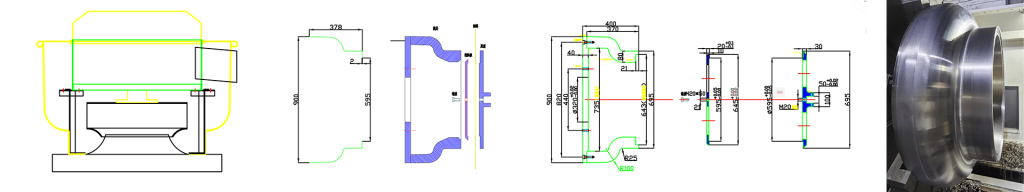

Design And Manufacture Of Spinning Molds For Aluminum Roof Fans

Spinning design and metal solution for upward-blowing roof fans: The bottom of the wind tube is a flange hole with a diameter of about 50-60mm, and the bottom is a flange hole;

If the diameter is processed by metal spinning with a disc, it must be processed by laser cutting or customized punching tooling in the later stage, which is very difficult and cumbersome, and the efficiency is greatly reduced!

The flange hole is cut before the spinning process and then the metal spinning process is performed, and the problem of demolding cannot occur. Due to the pneumatic demolding function of the conventional spinning machine, it is impossible to inject gas pressure between the mold and the product!

Solution: As shown in the figure,

- Design the bottom mold of the mold as a separate movable flange; the larger one needs to reduce weight while considering the pressure and positioning strength of the flange;

- Design a positioning groove between the disc flange on the tailstock pressure plate, place the disc on the tailstock stop, and design a quick locking mechanism in the middle flange to facilitate rapid production;

- Design a tapered guide at the main position of the mold so that the hydraulic tailstock will not be affected by gravity when moving forward, causing the flange hole of the accessory to be out of center with the outer diameter of the product;

- When the spinning process is completed, the blowing function and the retreat function of the tailstock cylinder work simultaneously to separate the roof fan shrouds from the spinning mold.

Other Cnc Spinning Roof Fan Parts

|

|

|

|

|

|

|

|

|

If you are planning or producing roof fans, please contact me and Joby engineers will give you a detailed plan.

Altron’s Factory Video

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| AC-800 | 800 | 400 | 600 | 40 | 20 | 18.5 | 50-1000 | 5 / 3 / 2 |

| AC-1000 | 1050 | 450 | 650 | 40 | 20 | 22 | 50-1000 | 6 / 4 / 3 |

| AC-1200 | 1250 | 480 | 800 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| AC-1400 | 1450 | 650 | 800 | 70 | 50 | 37 | 50-500 | 10 / 6 / 4.5 |

| AC-1600 | 1650 | 680 | 800 | 80 | 50 | 37 | 50-500 | 10 / 6 / 4.5 |

| AC-2000 | 2000 | 750 | 1250 | 140 | 100 | 55 | 20-400 | 14 / 10 / 7 |

| AC-2500 | 2500 | 800 | 1750 | 200 | 140 | 90 | 20-300 | 14 / 10 / 7 |

| AC-3000 | 3000 | 900 | 2000 | 200 | 160 | 115 | 10-250 | 14 / 10 / 7 |

Machine Configuration Parameters

Technical index

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The AC2000 Single Wheel CNC Spinning Machine has transformed our metal spinning process. Its precise control and repeatability have allowed us to achieve exceptional results with ease. Highly recommended!

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The AC2000 has exceeded our expectations in terms of efficiency and versatility. Its user-friendly interface and adjustable tooling options have made component shaping a breeze. We are thrilled with the exceptional results we have achieved

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

Thanks to the AC2000, we have been able to streamline our metal spinning operations. Its robust construction and comprehensive safety features ensure a secure working environment, while its maintenance-friendly design has reduced our downtime. An excellent investment for our manufacturing facility

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We are extremely impressed with the performance of the AC2000 machine. It offers outstanding stability and accuracy, resulting in flawless shaping of cylindrical components. Our productivity and product quality have significantly improved.