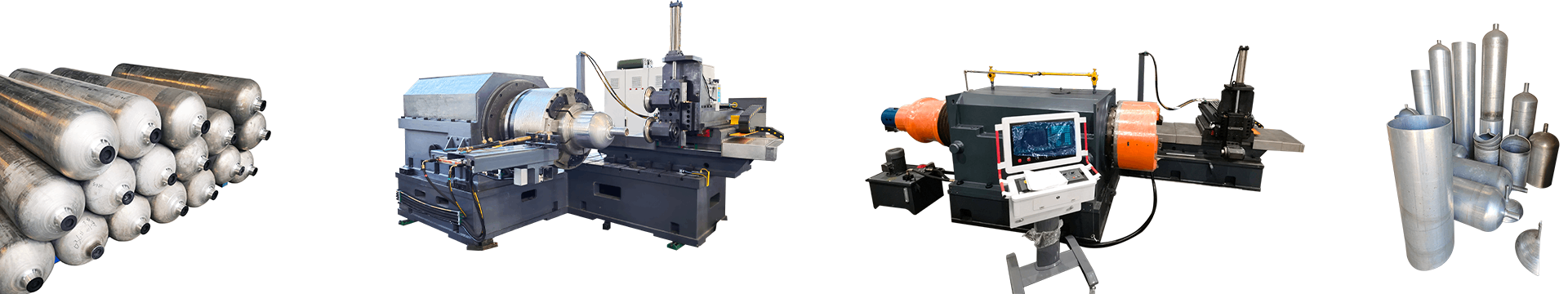

Necking CNC Spinning Machine AC-SK460

Necking Spinning Machine For Oxygen Cylinder

|

Machine Name |

Necking CNC Spinning Machine |

|

Model |

ACSK-460 |

|

Application Industry |

Hydrogen Cylinder, Gas Cylinders, Pressure Vessels,Cylindrical Tube Necking, Medicine, diving, automobile, etc. |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/Online Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

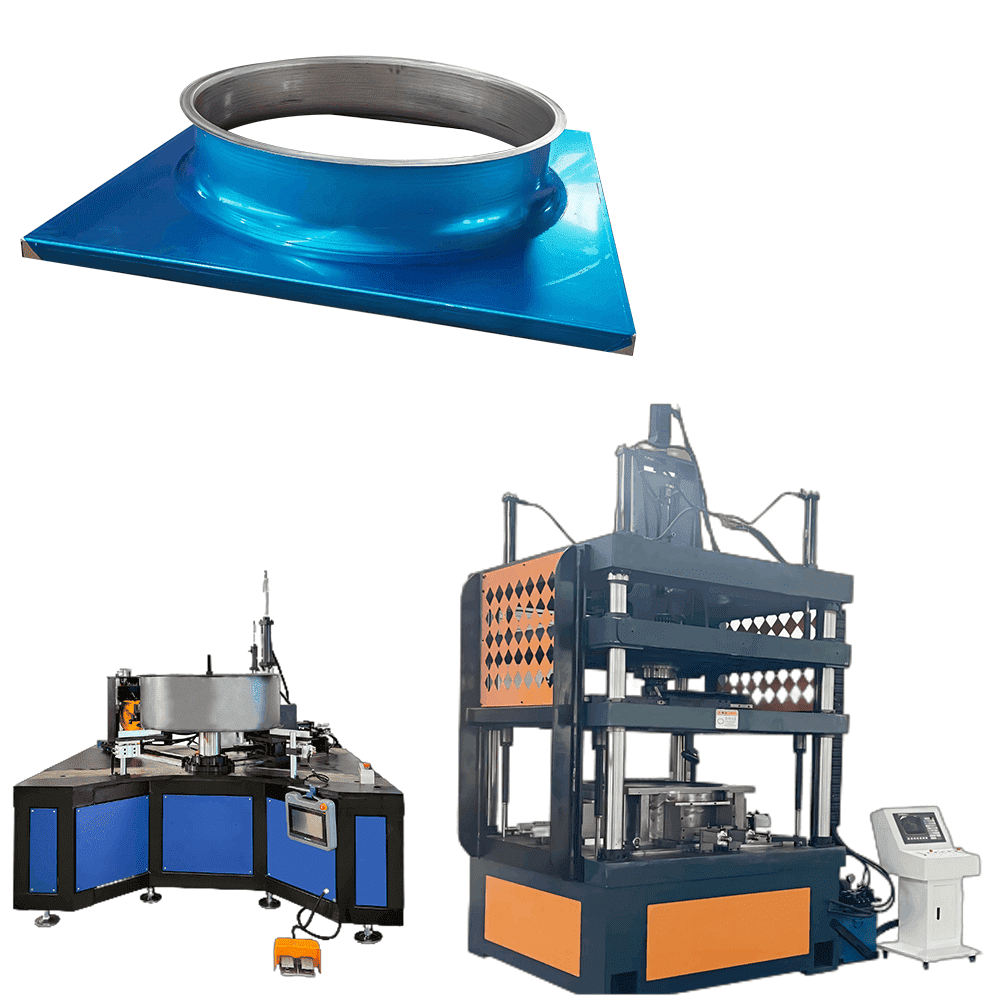

Seamless pressure vessel cylinders are mainly used in breathing, CNG, high-pressure gas transport cylinders and other fields.

4-Major Types Of Seamless Cylinders:

- Steel seamless cylinders,

- Aluminum alloy cylinders,

- Composite steel liner cylinders

- Composite aluminum liner cylinders

The traditional production method is to stamp the bottle shoulder and bottom, and then weld them with the tube blank or roll welding bottle body. Not only is the manufacturing process complicated and costly, but the product sealing and pressure bearing capacity are not ideal.

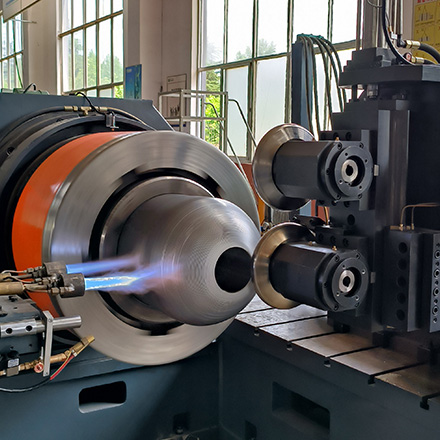

The spinning neck process has gradually become the core technology for the production of seamless cylinders. The spinning process for producing cylinders eliminates the defects of traditional cylinders in production, such as welds that cause reduced pressure strength and brittle cracks! The airtightness and pressure resistance parameters of cylinders manufactured by spinning have been greatly improved.

Advantages Of Oxygen Cylinder Spinning Process

- Increase the density of bottle body tissue and fiber tissue distribution, cold spinning bottle body thinning technology, the bottle body becomes stronger!

- Uniform wall thickness and reduce roughness, the spinning process can make the wall thickness uniform, the tolerance reaches ±6%, and the surface roughness value does not exceed 12.5µm!

- The spinning process improves the mechanical properties of the bottle body and withstands high pressure and impact!

- Bottle bottom thickness and enhancement: Through the hot spinning compression neck process, infrared temperature sensor temperature, auxiliary heating spinning ensures temperature control during the metal forming process, increases its thickness, and enhances the durability and safety of the bottle bottom

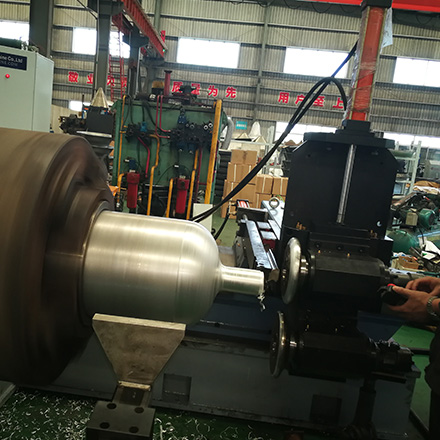

Video Of Necking Spinning Machine For Oxygen cylinder

Altron’s Gas Cylinder Metal Neck Spinning Case

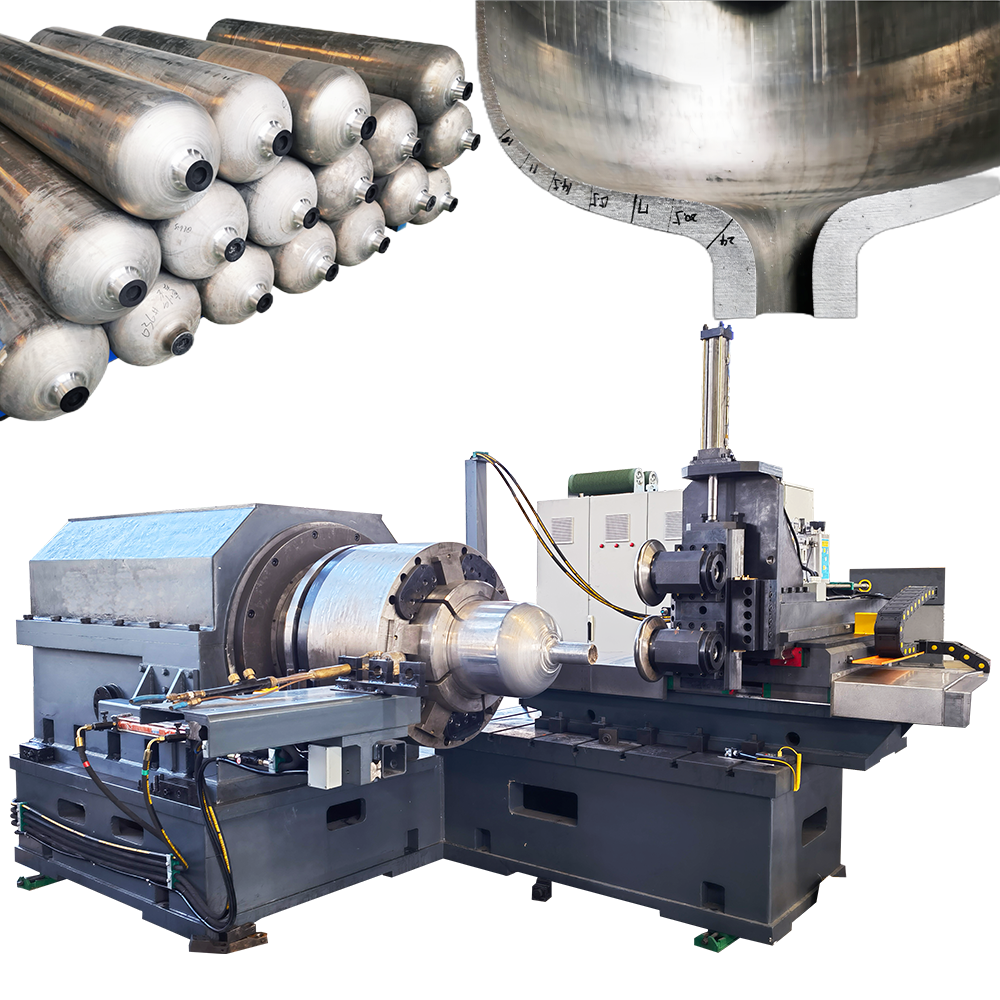

CNC Neck Spinning Machine Assembly Area

|

|

How to use Flow Forming & Necking Machine to make hydrogen cylinders

The whole process of aluminum alloy gas cylinder liner production

Configuration

Standard Configuration

- SIEMENS CNC 840/ 828D

- SIEMENS Servo Motor & Drive

- Spindle SIEMENS Servo Motor & Driver

- Apex Servo Reducer

- Heavy Load Double Nut Servo Driven

- High Strength Casting Turret Seat

- High Strength Ductile Iron Sliding Table

- High Rigidity Heavy Spindle Structure

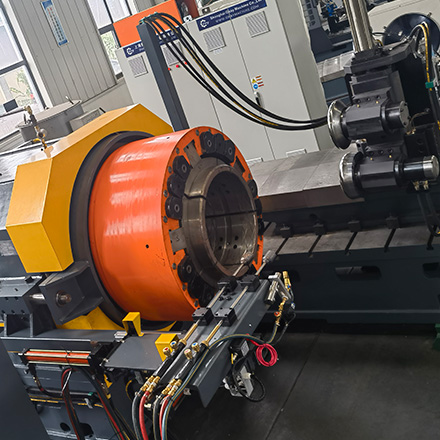

- Spinning Wheel with Hydraulic Motor

- Large Flow Circulation Cooling System

- Heavy Load Roller Guide

- Self-developed Spinning CAD

- CNC System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- The Grinding Head Device

- Customized Manufacture for Hot

- Auto Loading & Unloading Mechanism

- Double Wheel Feeding Slide

| Model No. |

Machining Dia. Range (mm) |

Forward Length (mm) |

Clamping System |

Clamping Force (KN) |

Feed Thrust (KN) |

| ACSK460 | ≤460 | 3000 | disc spring | 120 | 90 |

| ACSK640 | ≤640 | 3500 | disc spring | 150 | 110 |

| Model No. |

CNC System (KN) |

Power (KW) |

Heating Mode |

Operating Weight (KG) |

| ACSK460 | 828D | 110 | natural gas + oxygen | 23000 |

| ACSK640 | 828D | 135 | natural gas + oxygen | 26000 |

Machine Configuration Parameters

Technical indicators

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The ACSK Series machine has revolutionized our cylinder liner production. It delivers high productivity and exceptional product quality, exceeding our expectations

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

We are extremely satisfied with the ACSK Series equipment. Its smooth operation and reliable functionality have significantly improved our manufacturing process

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The ALTRON FB machine from the ACSK Series has transformed our cylinder liner production. The CNC dividing punching and excellent product compatibility have resulted in superior homogeneity and compatibility

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

The integration of the SIEMENS control system and programming software V4.0 has made operating the ACSK Series machines effortless. It offers precise control and exceptional repeatability, enhancing our manufacturing efficiency